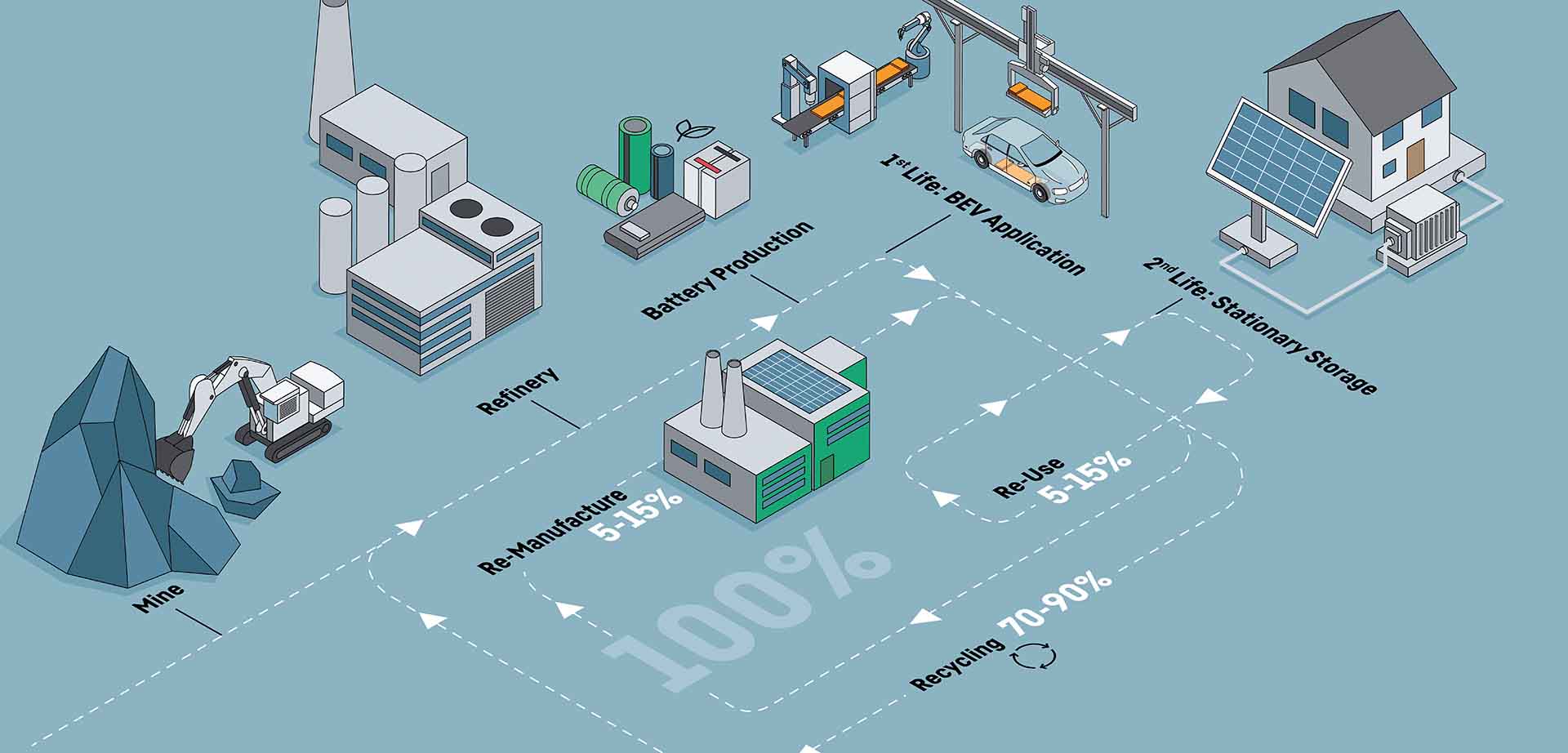

Non-destructive disassembly of battery packs

Sustainability goals and increasing raw material prices are making the recycling of batteries from electric vehicles an increasingly pressing issue for the automotive industry. To recover the valuable raw materials and components from the battery packs, they must be disassembled and sorted at the end of their service life. Automated processes provide a basis for economic dismantling while minimizing the hazards to employees from high-voltage equipment. Liebherr-Verzahntechnik GmbH uses its tried and tested automation technology for this and is working with research and industry to develop scalable, flexible solutions for the automotive and recycling sectors.