Service without borders

Minus 27 degrees! These February days in Mockfjärd are bitterly cold. It's good that the timber processing machinery here in deepest central Sweden has been tried and tested in snow and frost, as even at polar sub-zero temperatures, trucks carry on bringing their loads of pinewood logs to the Moelven Dalaträ sawmill. This is where the roundwood is sawn up for further processing into windows, interior panels and flooring. The unloading of the trucks and handling of the logs just has to keep going – at all times.

Conny Lind is fully aware of this. This morning, he is using his L580 LogHandler XPower® to grab the logs from the timber transporter and place them like pick-up sticks on the conveyor belt, which rumbles loudly under the frosty load. It transports the timber directly to quality control and processing.

No room for delay

Shortly after eight o'clock, the service icon lights up on his machine. After 1,000 operating hours, the machine reports it is advisable to carry out a service and replace any worn parts. "Tomorrow would be a good time for a service", thinks Conny Lind to himself, as the schedule indicates that it will be a quiet day in terms of incoming log deliveries. The day after tomorrow, on the other hand, large deliveries from Swedish forests are scheduled. All the machines will have to be up and running then.

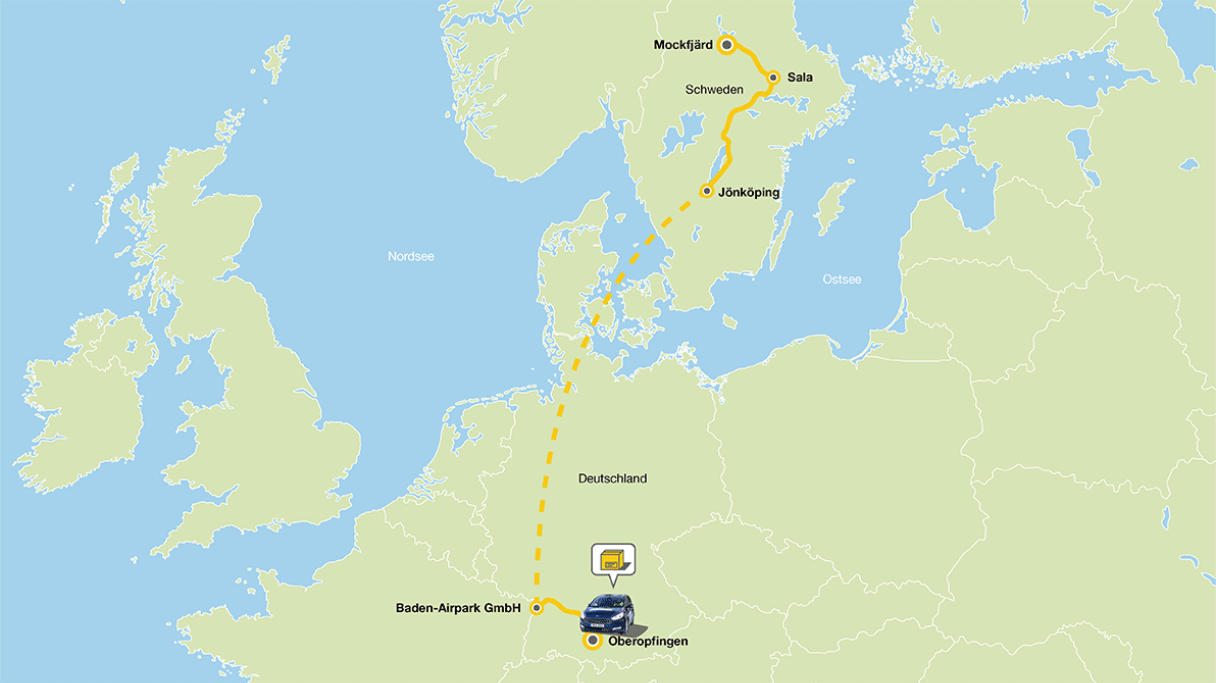

Shortly after ten o'clock, Conny Lind telephones his Liebherr partner in Västerås, 160 kilometres away. The dealer immediately checks the availabilities in the system and the relevant service engineer is put on standby for tomorrow. All that is needed now is to get hold of original spare parts. The ball is now in the court of the central spare parts warehouse for the Earthmoving Equipment division. That is almost 1,800 kilometres away in Germany, or to be precise, in Oberopfingen near Memmingen. 37 minutes later, at 10:37, the purchase order flashes up on the warehouse management system there.

A hundred thousand items – countless options

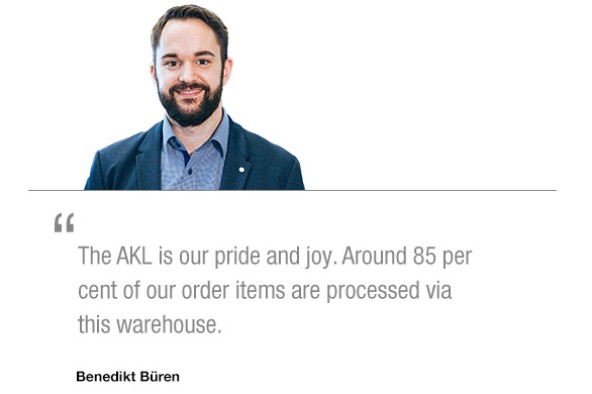

"Logistics is when everything runs precisely to plan." And that is precisely why Benedikt Büren finds his job so fascinating. He is Head of Service at Liebherr-Logistics GmbH. His workplace is the logistics centre in Oberopfingen, the central spare parts warehouse for Liebherr's Earthmoving Equipment division and Components division, which is located directly on the A7 autobahn. You can't miss it. The warehouse covers an area of over 47,000 square metres, has space for over 90,000 pallets and handles spare parts logistics, with 122,000 containers in the automated small-parts warehouse. "From here, Liebherr supplies around 122,000 items to customers all over the world", explains Büren.

A service package for an L 580 LogHandler XPower®: the order has just come in from Sweden. Benedikt Büren looks at the screen in the control room of the spare-parts warehouse: "It's already being processed", he says. The service package for the sawmill in Mockfjärd is one of up to 2,000 consignments which leave Oberopfingen every day for destinations worldwide.

Ordered today – dispatched today

"Depending on the delivery location, we can get deliveries underway on the same day for orders received before 17:30", says Büren. What makes this possible is the high degree of automation. It starts with information and data transfer and extends as far as the physical transportation of the goods. "Our aim", says the logistics specialist "is to ensure the maximum possible availability of spare parts." For the customer, this means maximum machine availability and the shortest possible downtimes during maintenance and service intervals.

The fact that the right package can be at the right place at the right time is largely down to the automated small-parts warehouse, known as the “AKL” for short. "The AKL is our pride and joy. Around 85 per cent of our order items are processed via this warehouse", says Büren. The service package for Sweden is constantly on the move from the moment the order is received: sophisticated conveyor technology takes it for commissioning, final checking and order-specific labelling and then on to dispatch, where in the afternoon it is handed over to the overnight express. The name fits perfectly for the Swedish package: Time matters – the clock is ticking. In Baden-Baden, the plane to Jönköping is already waiting.

"However, the handover to the carrier is far from being the end of the process for us", says Benedikt Büren. The Sales Order Tracking system, SOT, provides Liebherr and the sales and service partners with continually updated "live" information about precisely where the package is on its route to the customer. "This ensures that everything goes to plan – even for remote deliveries to the middle of the Swedish forest."

Consignment tracking

Always knowing precisely where a delivery is – "live" and in real time. Tracking and tracing (or “track and trace”, for short) is the term logistics specialists use to refer to the consignment tracking of packages and load units both internally within a company and externally. It provides the maximum possible transparency along complex supply chains. This information can be used to optimise flows of goods and processes and to reduce unused capacity, for example by making the planning of incoming and outgoing deliveries as exact as possible.

Tracking refers to tracking the flow of goods from "source to destination", while tracing refers to tracing back from the end customer to the point of primary production.

Liebherr has developed a technology of its own for this purpose: sales order tracking or “SOT" for short. Sales and service partners can use it to view the status of processing of their open and completed spare parts orders from anywhere and at any time.

In the right place at the right time

Sala, a good hour's drive north of Stockholm in the Swedish province of Västmanland, 6:40 am. Björn Lundin has made himself a coffee and is checking the order situation on his laptop. Today, the Liebherr service engineer has the service for the L 580 LogHandler XPower® in Mockfjärd on his schedule. The order is showing green in the Sales Order Tracking system. He can get started. Lundin now knows that the courier service dropped off the service package from Oberopfingen in his works vehicle during the night. It takes him just under an hour and a half to reach the Moelven Dalaträ sawmill in Mockfjärd. An hour and a half northwards through the deep snow and bitter cold of a Swedish winter.

Always available

Lundin is well aware that "machine availability is a must in the timber industry". "The equipment simply has to work – even under extreme conditions." Regular maintenance and servicing are therefore vital. "And if something should unexpectedly break down at some point, we can be on site to repair it within two hours."

Success according to schedule

At shortly before half past eight, Lundin has already opened the bonnet of the L 580 LogHandler XPower®. He carries out the maintenance step by step: replaces sealing rings and filters – working his way through the service package, completing everything according to schedule. The fact that in the L 580 LogHandler XPower®, as in all its construction machines, Liebherr manufactures all the key components itself, from the diesel engine and the hydraulic system to the steel structure, is very beneficial when it comes to servicing, says Lundin. "The layout of the machine is service-friendly, and all the maintenance points are always very easy to access. This makes my job easier, saves time and minimizes maintenance costs."

Servicing that makes money

The Liebherr service engineer is consequently welcomed with open arms by Peter Funk, the CEO of Moelven Dalaträ: "We process 280,000 cubic metres of wood a year at our site here. Keeping machines operating is vital for ensuring that we have the necessary capacity. Regular maintenance intervals are the key to this", says Funk. "So servicing is not an inconvenient cost factor. On the contrary, it helps us make money."

Once Björn Lundin has closed the bonnet of the Loghandler XPower® and stowed his tools away in his Sprinter, he notifies the Liebherr system via his laptop that the service chain has been successfully completed. Meanwhile, Conny Lind is already back at work in his Loghandler XPower®. He's ready for the next timber delivery.