Group

Group

Click RELEASE VIDEO and follow the data protection notices.

Paris: a city expanding

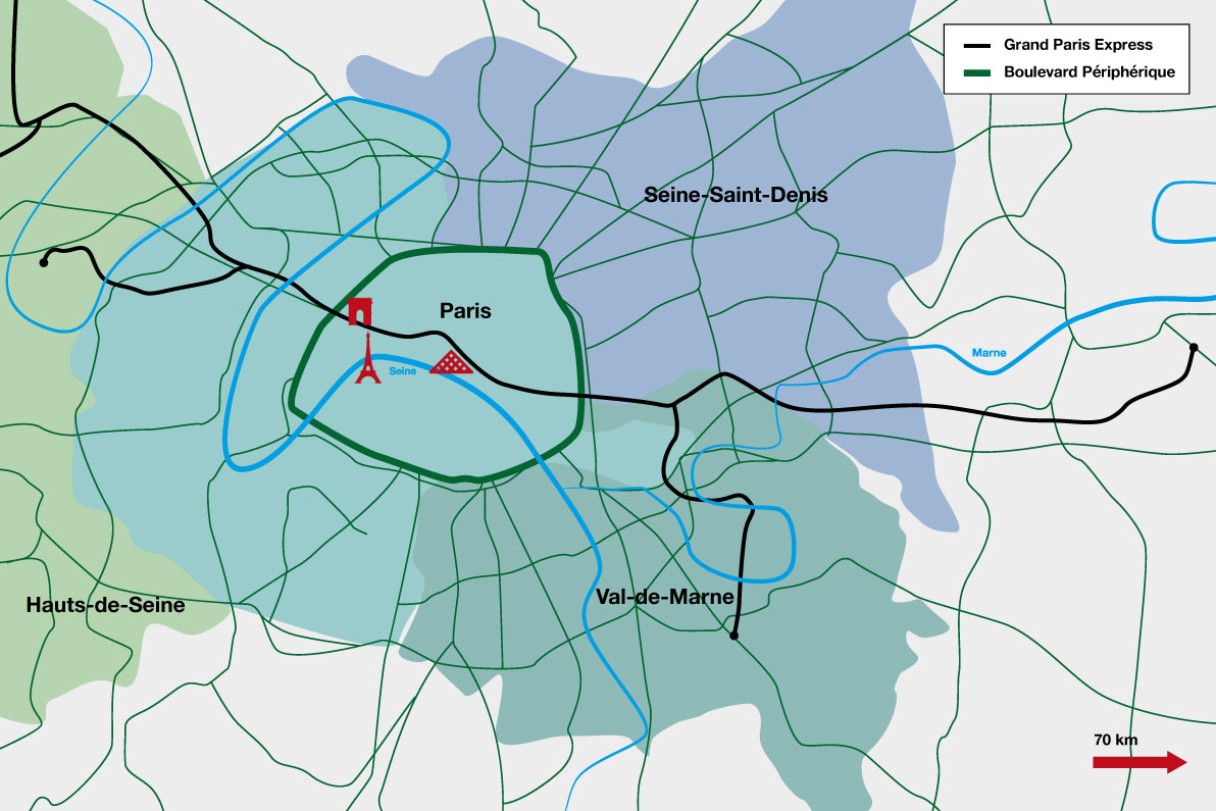

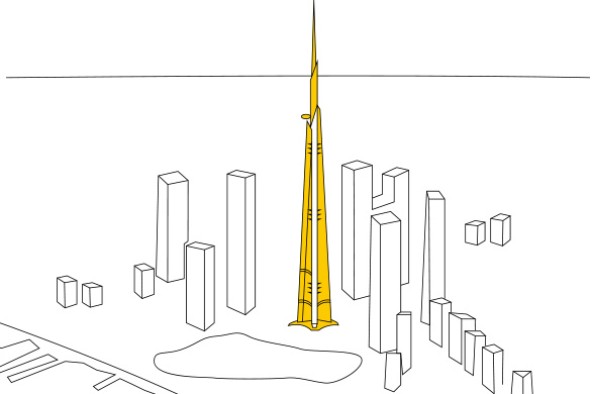

Around the site, it’s a daily frenzy, with motorcycles jostling for space, car horns honking, and the Eiffel Tower shrouded in smog. This doesn’t worry Philippe Schalbart. He has just left the permanent traffic jam on the Boulevard Périphérique, the overcrowded city ring road. “I would prefer to take the train to work”, the engineer says. “But I live outside Paris. And the rail links there are not good.”

This is set to change, and Philippe Schalbart is helping to make it happen. As Technical Director at construction firm Eiffage, his current workplace is a large construction site in the Parisian district of Batignolles, between the Arc de Triomphe and Montmartre. Portacabins, construction vehicles, machinery, materials – everything is crammed into the tightest space. Two Liebherr tower cranes rise around a shaft: a 630 EC-H 40 Litronic and a 280 EC-H 16 Litronic. It descends deep below ground, where an almost six kilometre long tunnel is being built, taking the Paris metro line 14 out to the northern suburbs.

Schalbart’s construction site is the first stage in implementing the “Grand Paris Express”. This new superlative metro line will make local travel easier in Paris, and prevent gridlock. Sixty-eight new stations are planned. They will function as nodes of urban development and economic growth, as Paris aspires to attain a leading position among world cities.

This video is provided by Google*. When you load this video, your data, including your IP address, is transmitted to Google, and may be stored and processed by Google, also for its own purposes, outside the EU or the EEA and thus in a third country, in particular in the USA**. We have no influence on further data processing by Google.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

The ground is like Swiss cheese

“Our tunnel consists of three parts”, Schalbart explains. “The first section links Gare Saint-Lazare with Pont Cardinet, where we are standing. Our tower cranes have already transported all the concrete components for the casing down below ground, and the tunnel is finished. Now drilling is proceeding further out of the city.”

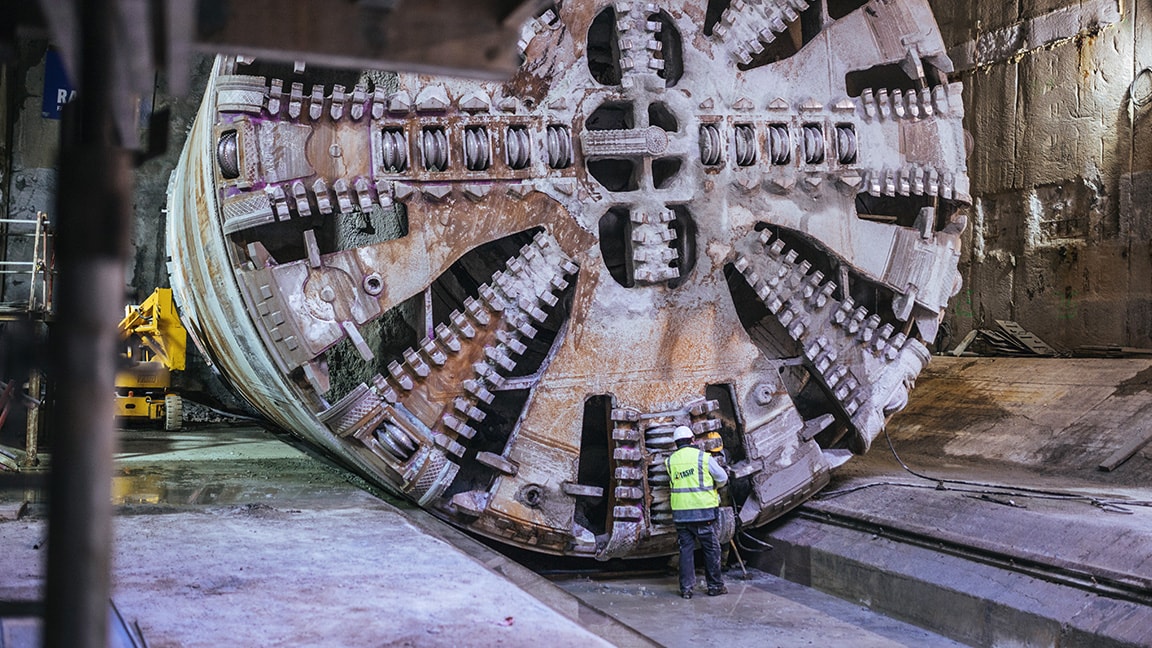

Building the Grand Paris Express is a very special challenge for the tunnel experts. “Paris is rightly compared to a Swiss cheese, because the ground is full of holes everywhere”, Schalbart adds.

At a depth of up to 35 metres, the gigantic tunnel boring machine has to pass beneath an existing railway line, another metro line, and a sewer. It eats its way forward at a rate of between two and four centimetres per minute. “Just from Pont Cardinet to Porte de Clichy, we excavated 84,000 metric tons of demolition waste and earth”, Schalbart says.

The construction project of a century

Grand Paris is approaching with big steps. Construction sites are everywhere. In the center as well as on the periphery. Cranes and construction machines from Liebherr are currently in use in at least eigth locations.

Location 1

Find out more

Location 3

Find out more

Location 5

Find out more

Location 7

Find out more

Location 2

Find out more

Location 4

Find out more

Location 6

Find out more

Location 8

Find out more

Faster to the destination

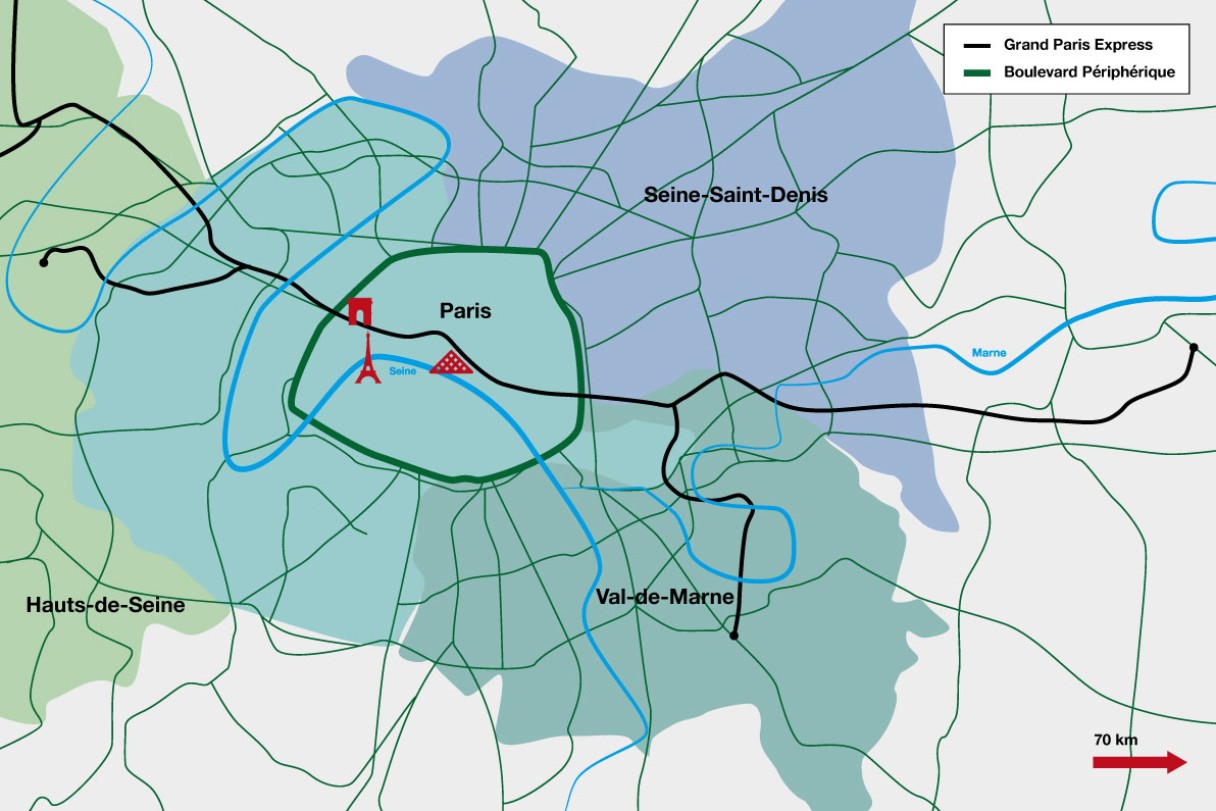

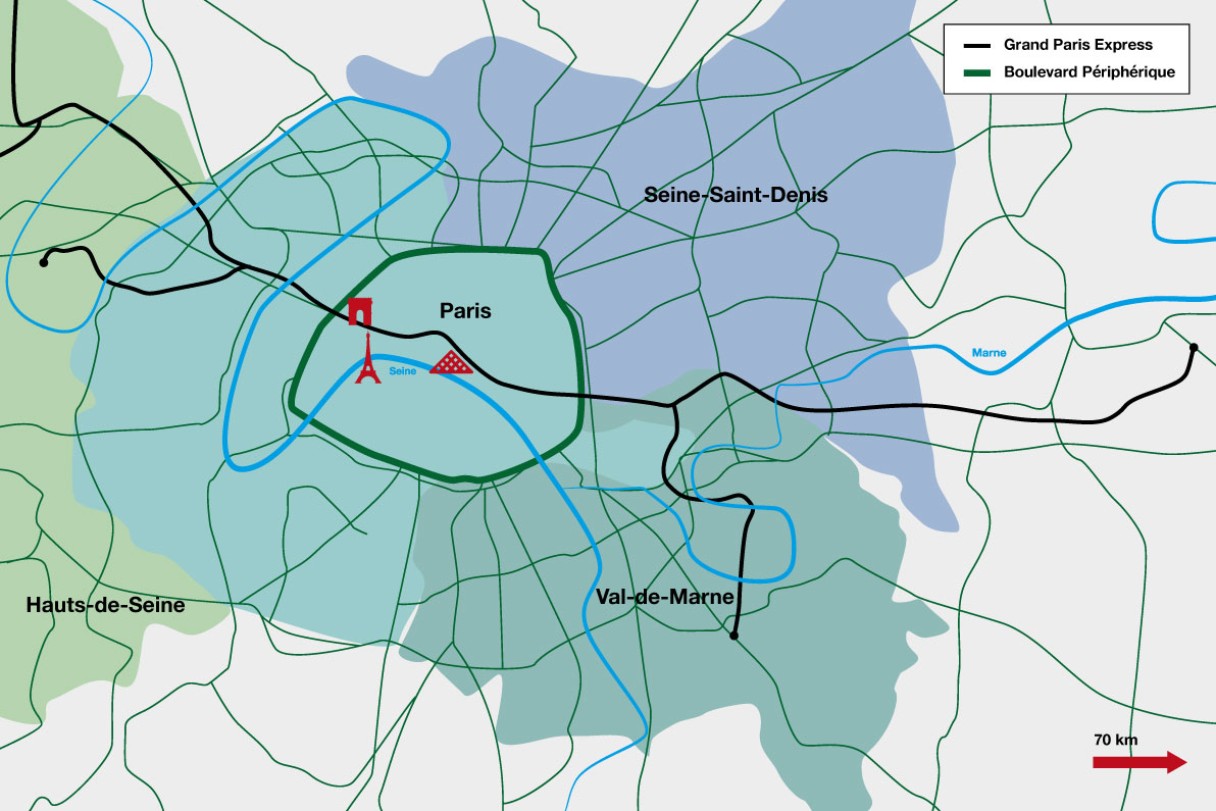

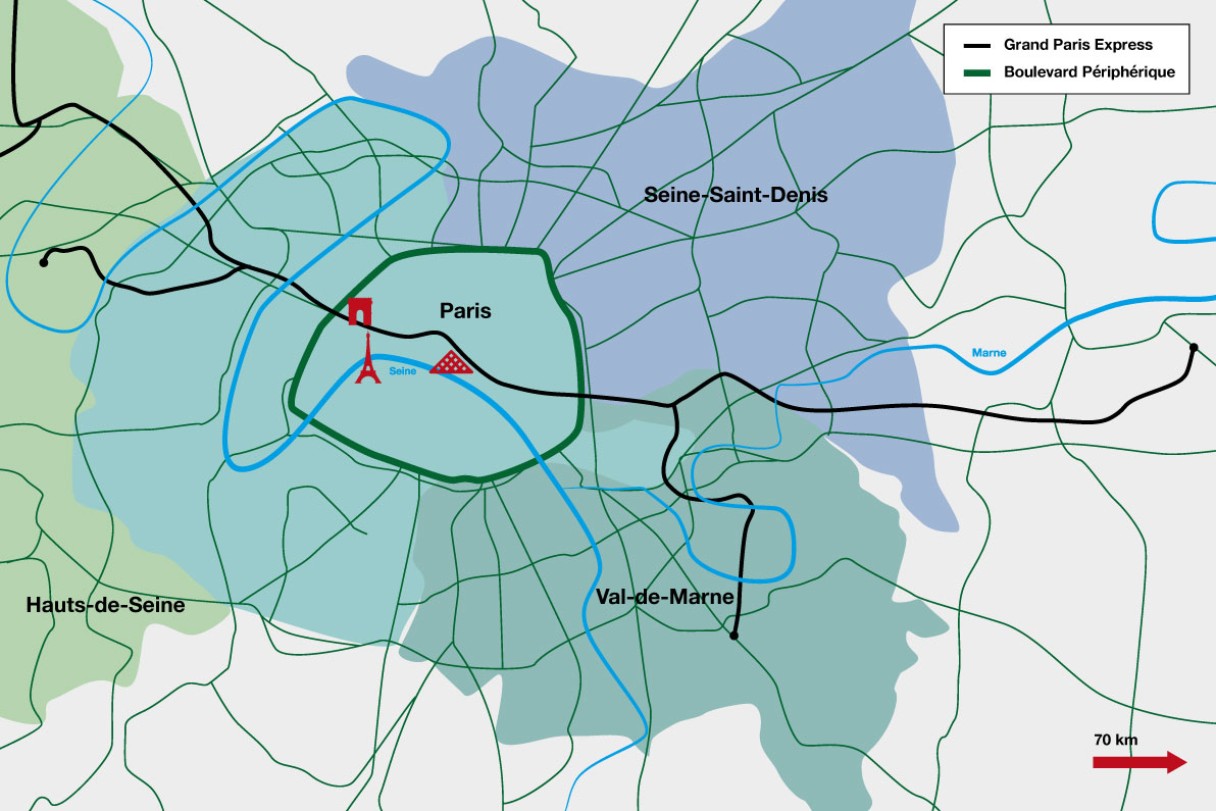

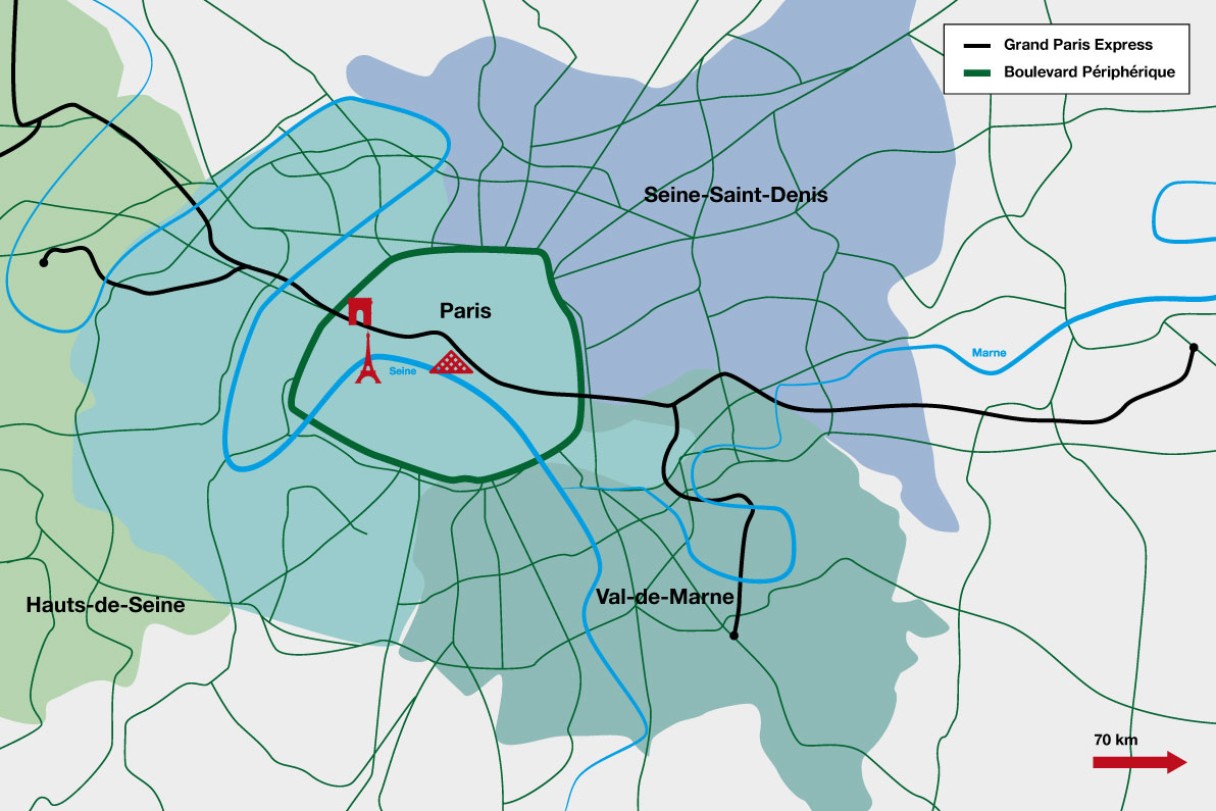

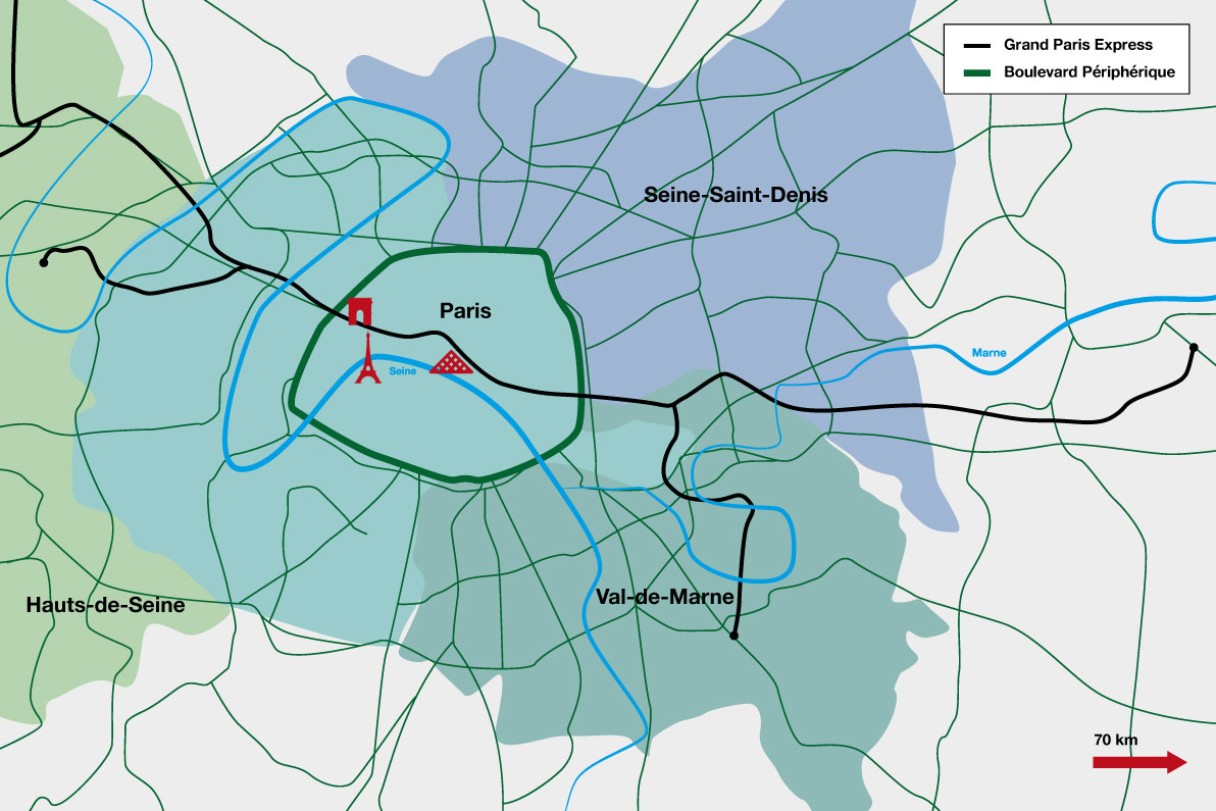

It is also about time that Paris moved beyond its borders. The city on the Seine is currently still the smallest of all major world cities. Only 2.2 million people live intra muros, as Parisians say, in an area of just 105 square kilometres. Extra muros – beyond the city gates – the population is twice or three times as large. Since the 1960s, a motorway ring road – the Boulevard Périphérique – has constricted the capital. With more than 21,000 inhabitants per square kilometre, the centre of Paris is almost as densely populated as Mumbai or Shanghai. So it is no wonder that people like Philippe Schalbart have to deal with the daily struggle of chronically congested streets.

It was France’s former president Nicolas Sarkozy who launched the Grand Paris project, completely by surprise, in 2007. Its goal is to catapult the city of museums into the top ranks of global megacities. The engine of this great transformation is the Grand Paris Express – comprising four new fully automated regional subway lines and the extension of two existing metro lines. By 2030, the planned lines will double the current public transport network from 200 to 400 kilometres, linking the suburbs around Paris with each other and with the city itself.

This video is provided by Google*. When you load this video, your data, including your IP address, is transmitted to Google, and may be stored and processed by Google, also for its own purposes, outside the EU or the EEA and thus in a third country, in particular in the USA**. We have no influence on further data processing by Google.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

A workplace with a view

On the Paris metro construction site, Thomas Brun confidently steers his tower crane over the shaft. From the cab 70 metres up in the air, he enjoys a unique panoramic view. The Eiffel Tower, the Arc de Triomphe, Notre-Dame cathedral, golden domes, Montmartre hill and the Sacré-Cœur church, the Seine river... But the crane operator is fully focused on the ground below him. On the hook of his 630 EC-H 40 Litronic, with millimetre accuracy, he manoeuvres three arch bricks over the shaft, before lowering the 21 metric ton concrete load. His colleagues then load the components for the tunnel walls onto a train that rolls them into the tunnel shaft. Soon this will become part of metro line 14. Brun pauses for a moment, leans back, and points to the neighbourhood around him. Other construction sites border on “his” construction site. “I can see how new buildings are springing up in this district”, says the 36-year-old.

Lifting with zoom

The large urban construction site, with its cordon of cranes, requires a special site architecture: “I can swing over the crane to my right, because I’m so high up”, Brun says. “If my crane was lower, I would get in the way of a third crane. The height of my crane was calculated exactly, taking all construction sites and cranes in the surrounding area into account.” When Brun transports heavy loads, he doesn’t just rely on his eyes. At a distance of 70 metres, he prefers to use the camera system at his side. The screen gives him an optimal view of the hook: “I can zoom in on the load, which means I can position it even more precisely.”

It is lunchtime. Thomas Brun’s shift is ending. Before he climbs down to the ground, he points to the north. “I live over there, behind the new Palais de Justice”, he laughs. “It’s great that I can play a part in modernizing my own neighbourhood.” In the future, he plans to leave his car at home more often, and definitely travel on the new line 14 that he and his colleagues are building.

Underground construction site – clearing the way for the new metro

The world's largest construction sites

Paris is not alone in aspiring to the superlative. Around the globe, people are fascinated by construction sites of breathtaking dimensions. They are beacons of world-class engineering ingenuity.

Saudi Arabia: from supertall to megatall skyscrapers

Saudi Arabia is reaching for the stars. On the west coast, the Jeddah Tower is currently under construction. At 1,007 metres, it is set to eclipse the Burj Khalifa, currently the world's tallest building at 828 metres. To put this in context: the Eiffel Tower, until 1930 the world's tallest man-made structure, is just 324 metres tall. The Jeddah Tower will house offices, residential space and a hotel. It is scheduled for completion by the end of 2019.

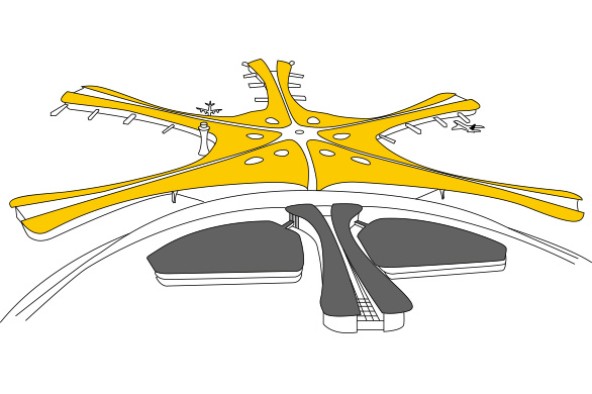

China: the world's largest airport

China's aviation industry is developing rapidly. 46 kilometres south of Beijing, the Beijing-Daxing airport is under construction. Initially, the passenger volume will be 45 million a year. However, with a maximum capacity of 100 to 130 million passengers, it could become the world's largest airport. To put this in context: with around 65.9 million passengers in 2016, Paris Charles-de-Gaulle Airport was in 10th place.

Everything gets used

It’s a good thing that at noon today, traffic out of the city is moving. Three trucks from Paris are taking demolition waste from the Grand Paris construction sites to Paprec, a recycling company situated on a dock on the Seine, north-west of Paris. An unloaded barge is moored on the wharf. Abdesslam Mouadni has been awaiting its arrival. He is sitting in his LH 24 M Industry Litronic. With its 12-metre reach, the mobile material handling machine quickly swings round to the giant demolition waste dump, moves its clamshell grab into the pile, and a short time later swings round again and drops its load into the waiting barge. Meanwhile his colleague, in a wheel loader L 546, heaps new demolition waste onto the pile.

Versatile in sustainability

“A lot is happening. The Grand Paris construction project is in full swing and all the demolition waste comes to us,” Mouadni says cheerfully. For him and his machine, there is plenty of work to do. But because the spoil heaps at Paprec are getting wider and higher by the day, they limit the space for manoeuvring. “This is where the new agile material handling machine really comes into its own”, says Mouadni.

This video is provided by Google*. When you load this video, your data, including your IP address, is transmitted to Google, and may be stored and processed by Google, also for its own purposes, outside the EU or the EEA and thus in a third country, in particular in the USA**. We have no influence on further data processing by Google.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

The demolition waste can come

Meanwhile, plant director Maxime Antonini is standing by the sorting machine. He is monitoring work on the conveyor belt, where his staff are sorting plaster and wood out of the demolition waste. “Our company has the most advanced sorting facility in the whole of France”, the engineer says with pride. “Every year, we recycle 200,000 metric tons of refuse, demolition waste and bulky waste. We can re-use 60 to 75 percent, depending on the material.” Paprec subsequently sells some of its recycled output as secondary building materials.

The Grand Paris Express is expected to generate as much as 43 million metric tons of demolition waste, or 33 million cubic metres – enough to dam an entire river. According to Antonini, this means excellent growth prospects for firms like Paprec over the next 20 years. There is no doubt about it: Grand Paris is building for the future – in every single phase of this historic large-scale construction project.