BluRoX: Innovative vacuum perlite insulation

The future is circular

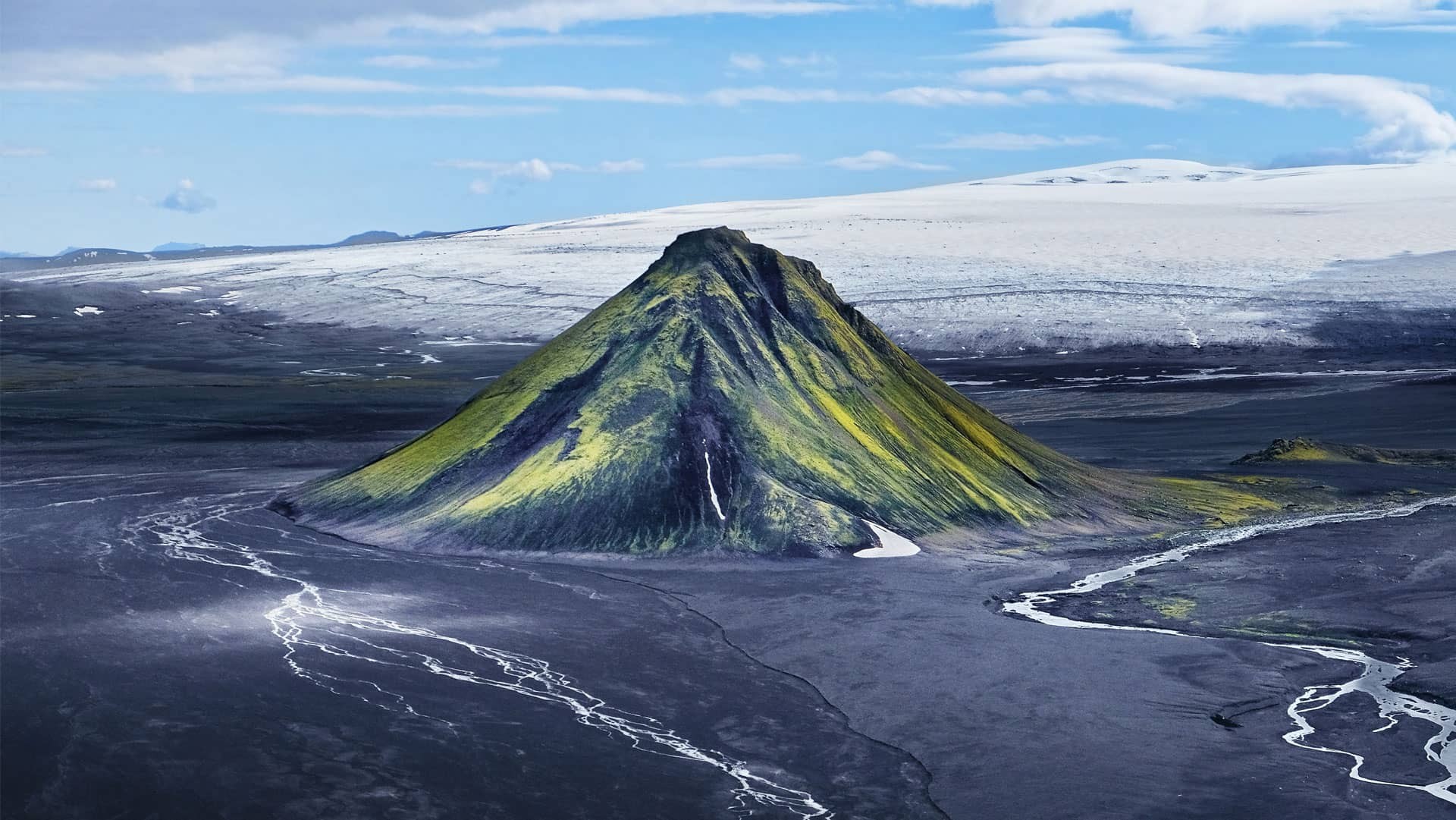

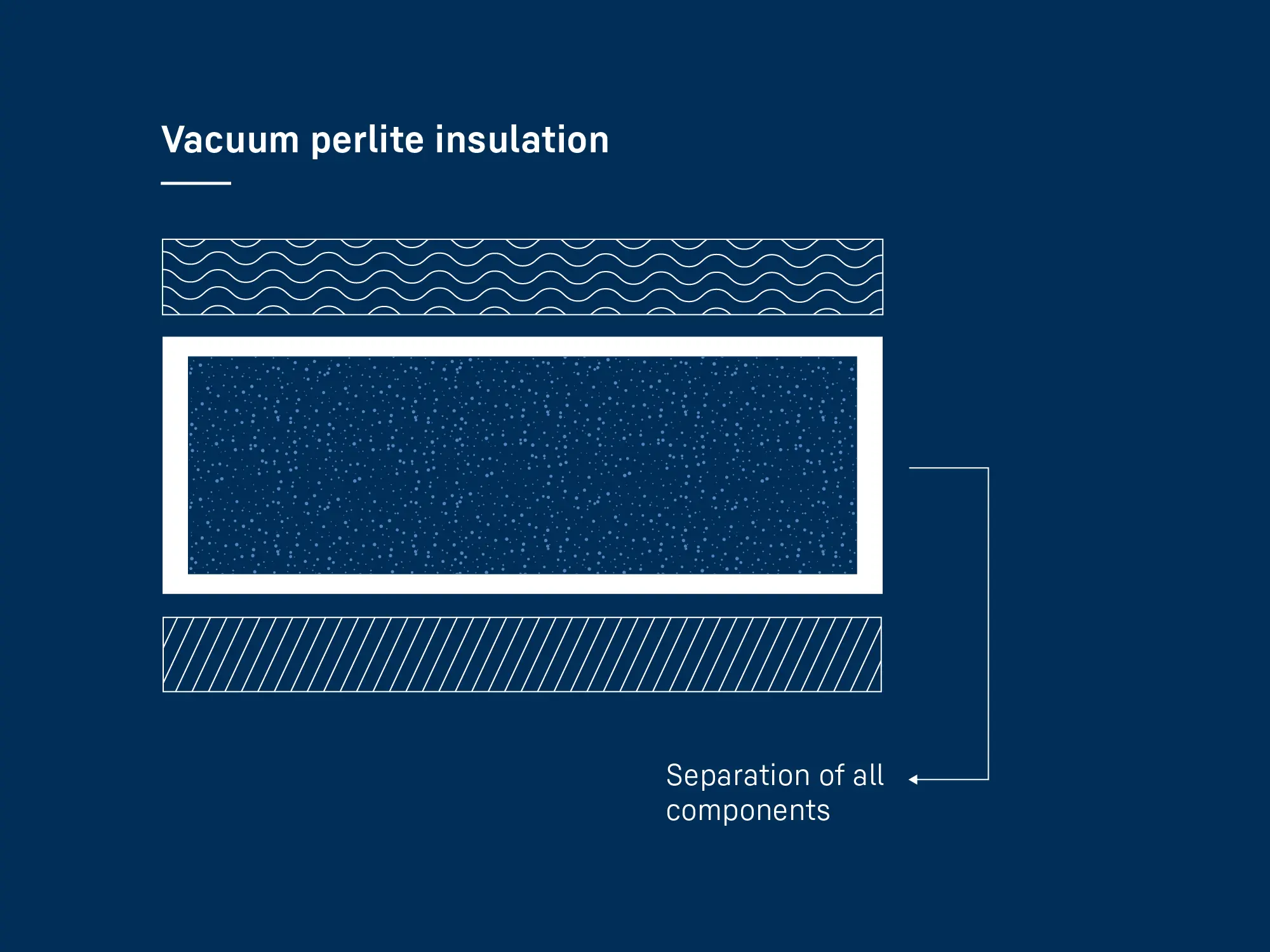

Our vacuum perlite technology is an innovation that will transform refrigeration and freezing. Introducing BluRoX. Instead of conventional polyurethane (PU) foam, this innovative technology uses a more effective form of cold insulation: a vacuum. Finely ground lava stone, known as perlite, stabilises the vacuumed components.

The Cradle to Cradle Certified® Certification

Cradle to Cradle Certified® is a prestigious certification standard for products designed for the circular economy. It evaluates products in five areas: material health, material reutilisation, renewable energy, water stewardship, and social fairness. Products are rated for their commitment to sustainability and continuous improvement.

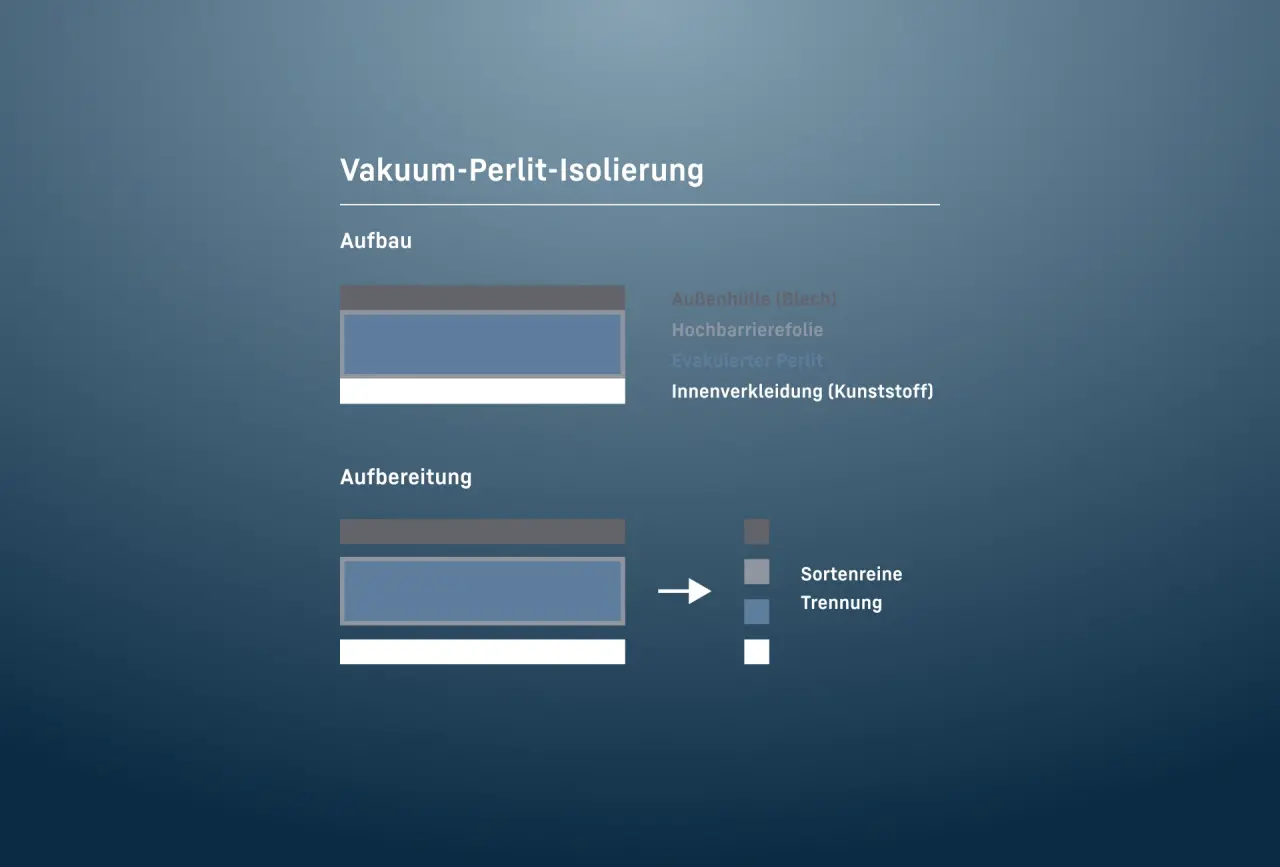

- Outer shell material

- High-barrier foil

- Evacuated perlite

- Interior lining

The outer casing is made of galvanized sheet metal, featuring a white lacquered exterior and a coated inner layer. These materials provide a sturdy structure for the appliance, support the white finish, and serve as the contact point for the door seal magnet.

The outer casing is made of galvanized sheet metal, featuring a white lacquered exterior and a coated inner layer. These materials provide a sturdy structure for the appliance, support the white finish, and serve as the contact point for the door seal magnet.

10 years in the making – Meet some of the people behind the revolutionary freezer in our FNXa 522i film.

About EcoVadis

We use EcoVadis to quantify our progress in the areas of corporate responsibility and sustainability. Our commitment to a holistic corporate strategy has now been rewarded: The EcoVadis gold medal and our position in the top 3% of all the award-winning companies makes it clear that we are facing up to ecological, social and ethical challenges.

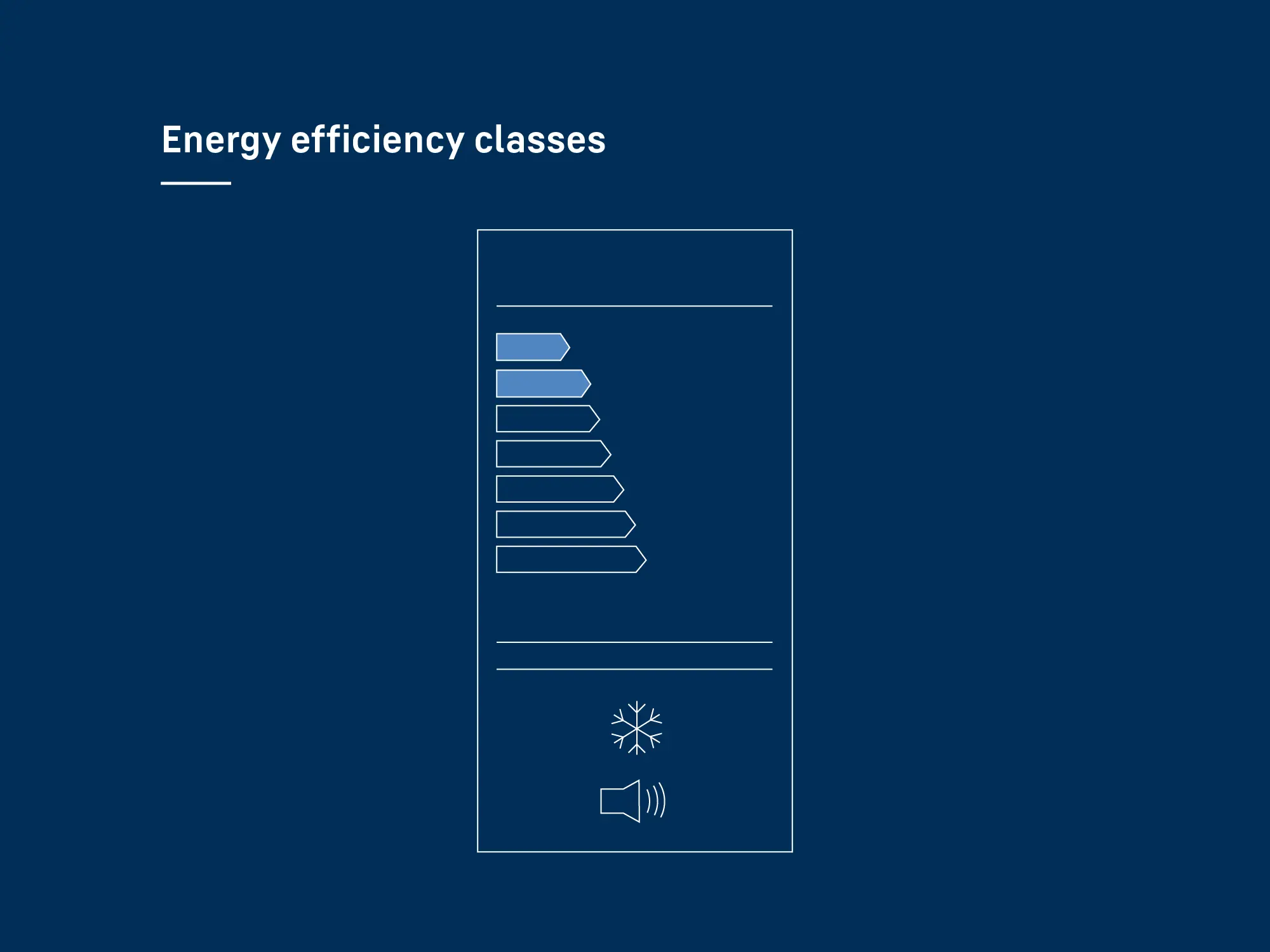

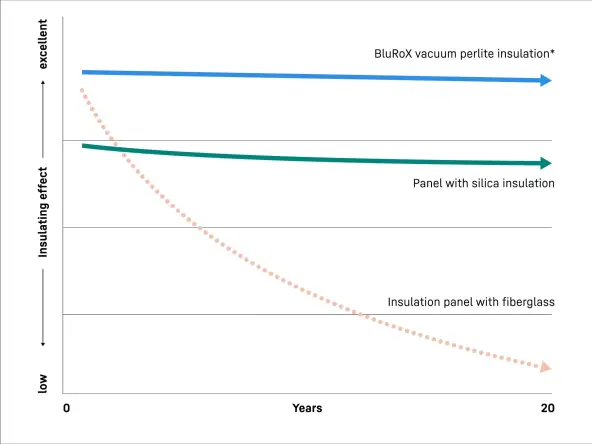

Efficiency of vacuum insulation over time

Our refrigeration appliances should work energy-efficient as long as possible. Therefore we use only durable vacuum insulation panels which age very slowly. For example: Our patented BluRoX insulation technology or vacuum insulation panels made of silica.

*The thermal conductivity of the evacuated perlite in BluRoX is higher than that of other vacuum panels. However, since the entire device is constructed solely from vacuum insulation, the overall insulating effect of the device is better.

The thermal conductivity values were determined through long-term measurement series with various samples in Liebherr's laboratories.

The FNXa 522i - The first Cradle to Cradle Certified® freezer

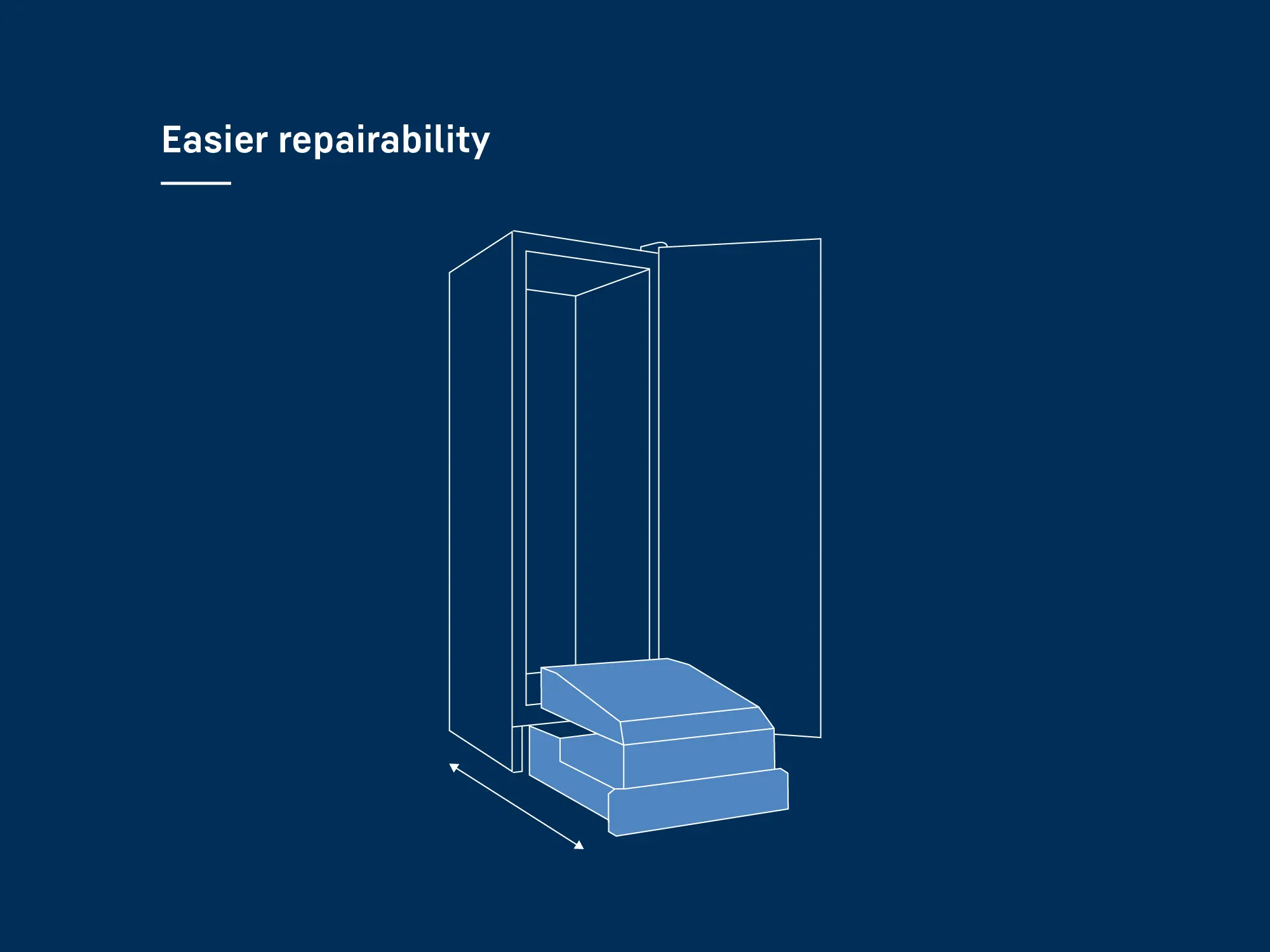

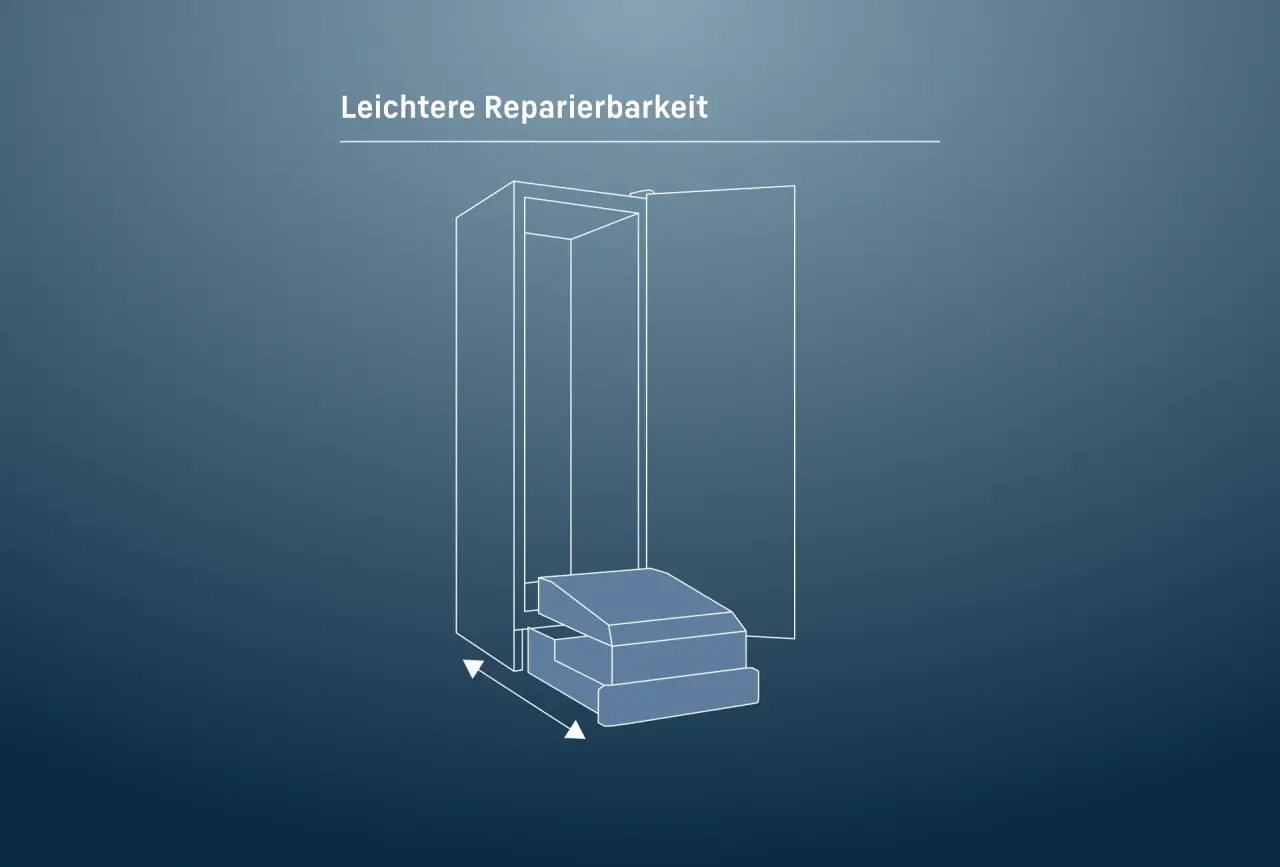

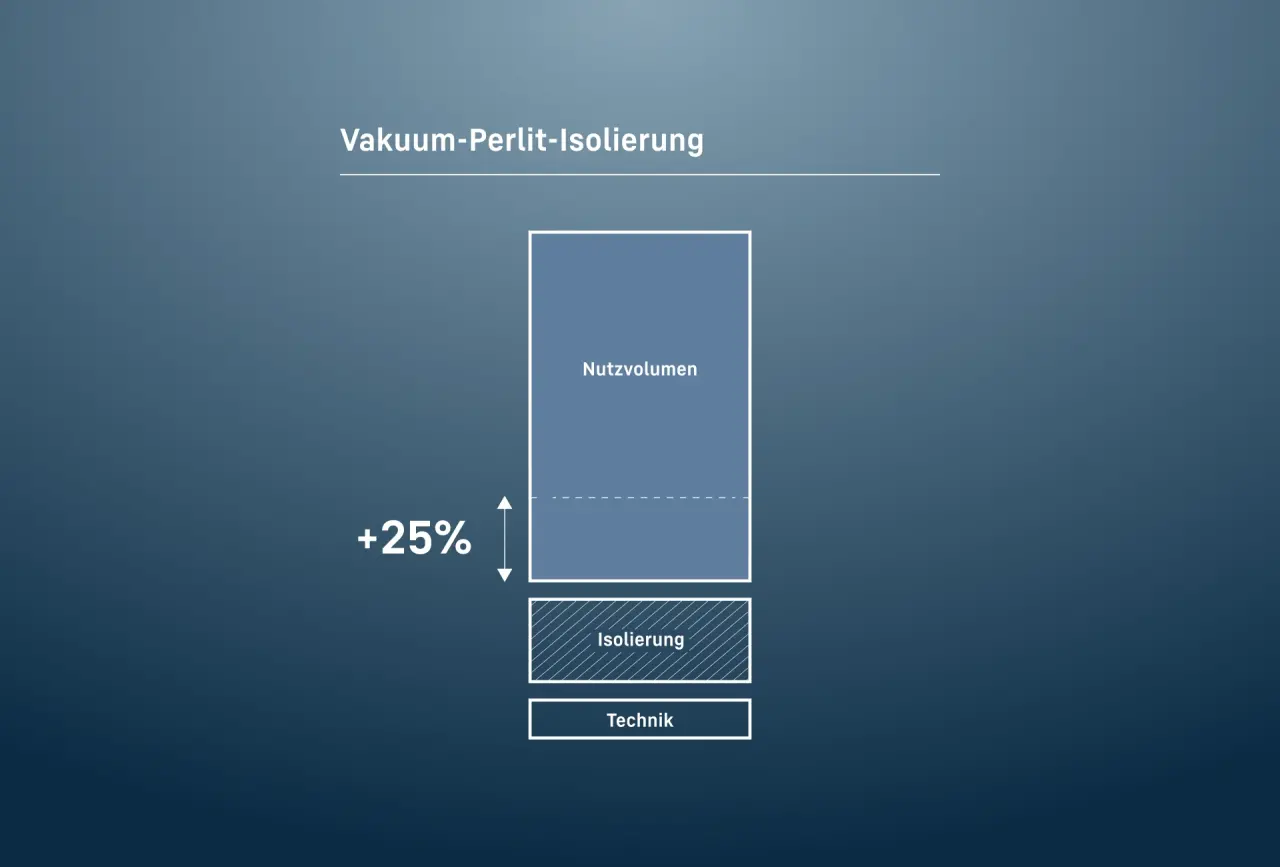

The Liebherr FNXa 522i freezer is coming and will be available 2026. Born from volcanic rock and over a decade of innovation, is unique in the market. It unites all the benefits of our BluRoX technology, ensuring unmatched energy efficiency (Class A) and up to 30% more storage. The base cooling module cassette ensures easy maintenance. Its circular design allows each component to be reused, earning the Cradle to Cradle Certified® Bronze certification. Our freezer is built for the eco-conscious consumer and steps towards a future that is not linear – but circular.

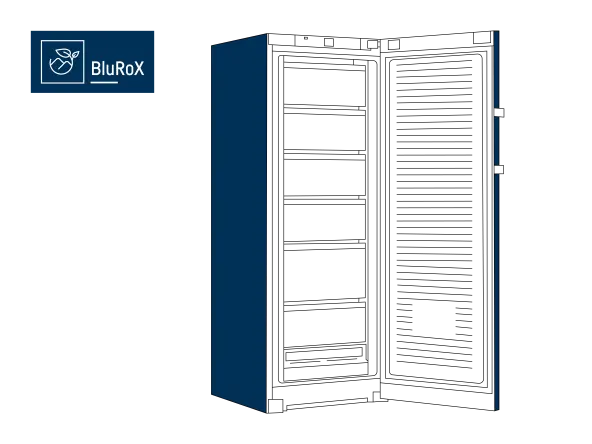

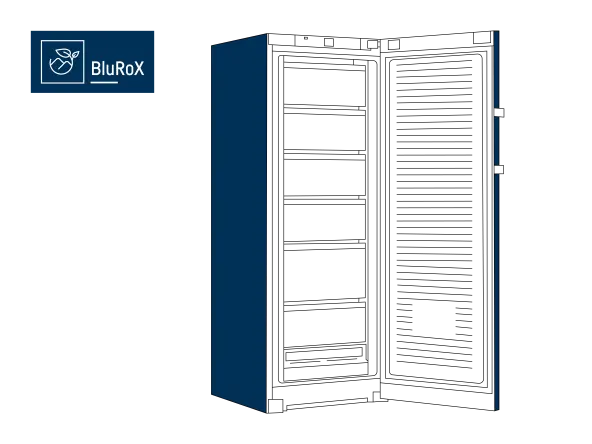

FNb 505i – our first freezer with BluRoX

BluRoX is already available – in the door of our FNb 505i freezer. The groundbreaking vacuum perlite technology offers an unprecedented and extremely efficient cold insulation. Thus, freezers can achieve top values in energy efficiency. In addition, the materials in the door can be sorted and reused at the end of their service life.

Exterior dimensions: height/width/depth - 165.5 / 59.7 / 65.5 cm

165.5 / 59.7 / 65.5 cm

Total volume - 238 l

238 l

Made in Germany

Our superior products offer premium quality, cutting edge design, and innovative features that best fit your lifestyle. The use of high quality materials, perfectly detailed finishes, and elite cooling components are combined with the latest production processes, resulting in an outstanding cooling product.

| Scope 1: | |

| Direct greenhouse gas emissions generated locally by the activities that an organisation owns or controls. | 1,428t CO2 eq. |

Scope 2: | |

| Indirect greenhouse gas emissions resulting from purchased energy. | 0t CO2 eq. |

| Total annual withdrawal (2022) | 12,319 m³ | Third-party fresh water. |

| Total annual discharge (2022) | 11,683 m³ | Discharge to third-party (without onsite pre-treatment) - only applies to the water use for hygienic purposes (toilets, hand washing) and/or in kitchens. |

| Total annual consumption (2022) | 636 m³ | The water contained in the painting system* is cleaned, evaporated and put back into circulation. Fresh water needs to be added from time to time to compensate the evaporated water - the system operates without wastewater. *The painting system is not part of the production process of all BlueRoX appliances -and will be phased out for all production processes at the complete production facility. |

| Water quantity by use cycle stage of BluRoX appliances | No water consumption in manufacturing-processes of BluRoX appliances. No water consumption in use stage. | |

| Physical risk Ochsenhausen: (Baseline water stress) | medium-high (20-40%) | Reference: AQUEDUCT Water Risk Atlas |

Materials

Materials used in refrigerators and freezers come into contact with food and must therefore meet specific criteria. At Liebherr, we ensure compliance with food safety standards.

We are committed to continuously increasing the proportion of recycled materials in the future.

Where do we stand?

Currently, we are unable to procure sufficient quantities of recycled materials for plastics and glass that meet these requirements. In the case of steel, the recycled content could not be reliably demonstrated by our suppliers.

About EcoVadis

We use EcoVadis to make our progress in the area of corporate responsibility and sustainability measurable. Our focus on a holistic corporate strategy has now been rewarded: being awarded the EcoVadis gold medal and being ranked in the top 3% of all award-winning companies clearly shows that we are tackling environmental, social and ethical challenges.

Freshness technologies

Energy efficiency

Excellent design

German engineering

Made in Germany

Our superior products offer premium quality, cutting edge design, and innovative features that best fit your lifestyle. The use of high quality materials, perfectly detailed finishes, and elite cooling components are combined with the latest production processes, resulting in an outstanding cooling product.

CO2 emissions (2022)

| Scope 1: | |

| Direct greenhouse gas emissions generated locally by the activities that an organisation owns or controls. | 1,428t CO2 eq. |

| Scope 2 | |

| Indirect greenhouse gas emissions resulting from purchased energy. | 0t CO2 eq. |

Water consumption (2022)

| Total annual withdrawal (2022) | 12,319 m³ | Third-party fresh water. |

| Total annual discharge (2022) | 11,683 m³ | Discharge to third-party (without onsite pre-treatment) - only applies to the water use for hygienic purposes (toilets, hand washing) and/or in kitchens. |

| Total annual consumption (2022) | 636 m³ | The water contained in the painting system* is cleaned, evaporated and put back into circulation. Fresh water needs to be added from time to time to compensate the evaporated water - the system operates without wastewater. *The painting system is not part of the production process of all BlueRoX appliances -and will be phased out for all production processes at the complete production facility. |

| Water quantity by use cycle stage of BluRoX appliances | No water consumption in manufacturing-processes of BluRoX appliances. No water consumption in use stage. | |

| Physical risk Ochsenhausen: (Baseline water stress) | medium-high (20-40%) | Reference: AQUEDUCT Water Risk Atlas |

Materials

Materials used in refrigerators and freezers come into contact with food and must therefore meet specific criteria. At Liebherr, we ensure compliance with food safety standards.

We are committed to continuously increasing the proportion of recycled materials in the future.

Where do we stand?

Currently, we are unable to procure sufficient quantities of recycled materials for plastics and glass that meet these requirements. In the case of steel, the recycled content could not be reliably demonstrated by our suppliers.

Innovative BluRoX technology from Liebherr

benefits both people and the environment

The basis: a revolutionary product design

Unlike the familiar vacuum insulation system with vacuum panels inside foam elements, the vacuum perlite technology in BluRoX appliances consists of a complete, stable 3D vacuum element.