Made with Liebherr

Renowned old towns and spectacular buildings, important communication infrastructure or just places for sport and leisure – Liebherr cranes are very much in demand for construction, modification and refurbishment work. So we can certainly also say: Made with Liebherr.

Toboggan run in low country

There are around two dozen indoor ski slopes for skiers and snowboarders on the European mainland. One of them is located at Bispingen, 50 kilometres south of Hamburg in the centre of Lüneburg Heath. In this winter simulation, which is called “Snow Dome” and features a 300 metre piste, winter sports fans can practise their Alpine skills and prepare themselves for their winter holidays even in northern Germany, which is predominantly flat. Even tobogganing is possible there.

The building for the very first winter sports arena in northern Germany was erected sixteen years ago to make this winter experience possible. The work involved several Liebherr construction machines. They included six LTM cranes provided by Austrian contractor Felbermayr. This small fleet of mobile cranes from the group outlet in Bautzen, Saxony (Germany) worked on the structural steelwork for the building for more than six months. Pillars, trusses and supports comprising a total of 3,500 tonnes of steel were used in the job. One of the cranes on the site was a brand new LTM 1095-5.1. Equipped with a hydraulic swing-away jib, at the time the crane, which you can see in the photograph second from the left, was absolutely essential for assembly work where there was little freedom of movement between sections which had already been completed. As an aside, the Dutch, who have one of the flattest countries in Europe, have the most indoor facilities for Alpine winter sports.

Spanning the Rhine with no supports

Even from a distance, travellers will immediately notice the unusual pylon that makes up part of the Lower Rhine Bridge near Wesel. This special landmark in the flat Lower Rhine landscape looks like an upside-down Y. The 130 metre pillar is the central element of this bridge design. The river crossing is known as an asymmetric cable-stayed bridge and allows the busy Rhine shipping traffic to continue to flow smoothly, meeting the demands for a bridge with no supports.

In addition to a Liebherr 280 EC-H 16 Litronic top-slewing crane, a powerful lattice boom crane from our plant in Ehingen was also involved in the construction of the massive pylon. The LG 1750 delivered plenty of power to the site, enabling it to position several 75 tonne steel blocks at a great height to complete the imposing pillar structure. The fact that this mobile crane, which is still in production, completed its job in just one day at the time, was very important as the high-water peak of a major flood was approaching from the south and reached the Lower Rhine just days later. It left the set-up area for the crane at the foot of the pylon under several metres of water for a lengthy period of time.

Lead-up to the Olympics

In the lead-up to the 2012 Olympic Games held in London, the idea of a cable car over the River Thames, which had first been conceived in the 1990s, was reprised. The aim was to link the Millennium Dome, the Olympic venue in Greenwich on the south bank of the river, with the sporting arena at the Royal Victoria Docks on the other side. The timetable for completing the cable car was drawn up in great haste and was extremely ambitious. Initially, the plan was to use a large mobile crane right next to the river, but this was abandoned due to structural problems with the surface of the bank. A new crane set-up area 120 metres away, however, meant that a significantly more powerful machine was required.

A Liebherr LR 11350 crawler crane from Weldex based in Scotland finally delivered the capacity and power required in the capital. The massive crane reached over the large distance from the site with its imposing 180 metre boom length, divided between the main boom and the lattice jib and using a total of around 1,000 tonnes of ballast. However, the lattice jib reached into the airspace and appeared on the radar of the nearby City Airport. This resulted in lots of interruptions on the site. Furthermore, the much-vaunted fog in London created even more delays in what was a very tight schedule to start with. Finally, a decision was made to continue the work at night. Lucky for us because it enabled us to produce this stunning night-time panoramic photograph. It shows our crawler crane hoisting the final large component weighing 71 tonnes onto the pillar and completing the 90 metre helical pylon. The illuminated buildings in the City of London and the bright Millennium Dome create a sparkling background for it.

Noiseless in Dresden old town

Radeberg-based contractor Krandienst Kunze e.K. sent its Liebherr MK 88 Plus mobile construction crane to Dresden old town to replace glass elements in a shopping arcade. The conditions in the area around the Frauenkirche include narrow streets, requiring sensitive hoists from the atrium over a line of buildings thirty meters high and a high density of local residents. So it was an absolutely ideal job for an MK 88 Plus operating in electric mode. Hardly had the hydraulic outriggers been extended and the vehicle levelled, something happened which was extremely unusual for a crane job – complete silence. The diesel engine had been shut down and from then everything was carried out using site electricity, even the remainder of the set-up process for the MK. The heavy current cable carried on the crane was connected to the power distributor box on the site and the elegant extension mechanism for the tower and boom were started using the remote control. 15 minutes later, the compact MK was fully erected with its boom at an angle of 30 degrees. Only for the first few hoists was the MK 88 Plus controlled from the infinitely height-adjustable elevating cab to keep a close eye on the building topography. After that, everything was done by remote control so that the operator was with the installation team on the roof, close to the removal and installation location for every one of the 800 kilogram glass elements. That made communication and a view of the load much easier. And it also meant that the job in the old town could be completed successfully with maximum safety and with pretty much no noise.

Wooden cupola becomes new salt storage facility

In Switzerland, there is a statutory supply order for salt. Schweizer Salinen AG, owned by all the Canton’s and the Principality of Liechtenstein, produces almost all the country’s requirement of salt of all types at its three sites. One of them is Saline Riburg near Rheinfelden, around ten kilometers west of Basel. Its storage capacity was expanded around ten years ago with a large new facility after an extremely snowy winter and problems with the supply of winter salt. A Liebherr LTM 1055-3.1 mobile crane took care of the panelling of the massive cupola structure. Around 1,300 cubic meters of timber were required to build the dome which has a diameter of 120 meters and a height of 32 meters. The wooden structure, which at the time was the largest wooden cupola in Europe, can hold over 100,000 tonnes of salt.

The ultimate salt barrel

Schweizer Salinen produce up to 600,000 tonnes of salt every year. In addition to table salt and salt types for industry, agriculture and pharmacy, the Alpine state also requires a great deal of winter salt. Enormous warehouses such as the Saldome2 at Saline Riburg in the Canton of Aargau are used to store enormous stocks of this important material. A Liebherr mobile crane was involved in the construction of the wooden cupola.

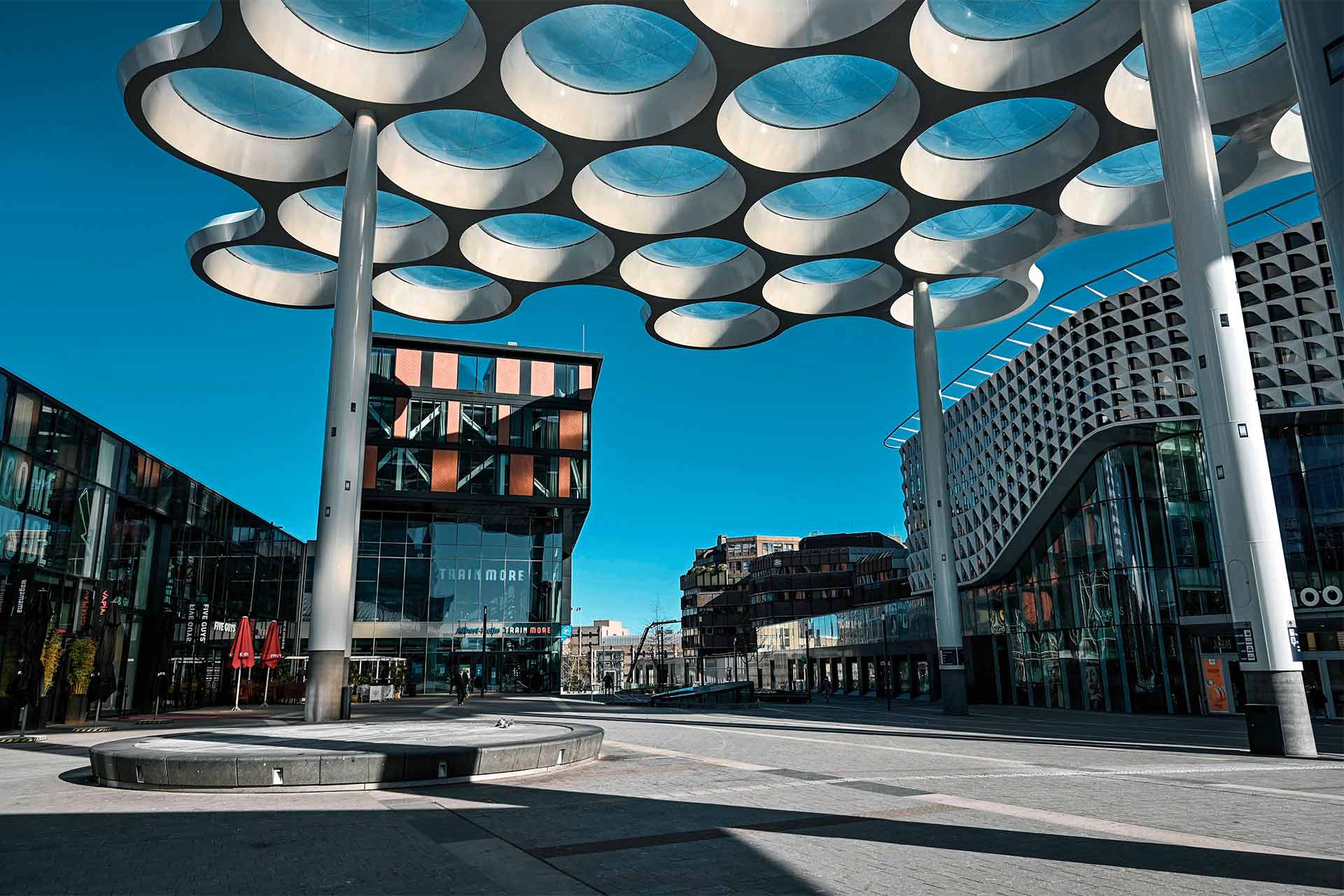

8-axle crane at the new station

Utrecht station is the largest railway station in the Netherlands. It handles around 195,000 passengers and 1,500 trains every day. First opened in 1843, it has been extended and refurbished several times. The station itself was recently reopened in 2016 after extensive building work and the area around the station has been completely restructured, with the work finishing in 2020. One striking feature is the new roof on the station square – which is where an LTM 1450-8.1 from crane contractor Heijkoop was in action in May 2018. The constricted site conditions on what is now the station square posed a minor challenge. A 1000 EC-H tower crane was dismantled whilst site operations continued. Fitted with a luffing jib and 134 tonnes of ballast, the components of the tower crane were hoisted out of the new roof of the station square. The slewing ring with the crane jib, weighing in at around 27 tonnes, was the heaviest load for the 450 tonne crane.

Modern Dutch architecture

An LTM 1450-8.1 played a major role in the construction of the new railway station in Utrecht in May 2018. The station will handle around 1,500 trains every day.