The best of all worlds

They say that all roads lead to Rome. And the same applies to sustainable development and climate-friendly technology. An openness to technology of all kinds is a must in order to address the diverse requirements of commercial vehicle transport, on construction sites, mines or off-road. This is where the future lies.

Jürgen Appel, head of technology coordination, Liebherr-International AG

No shortcuts to climate action

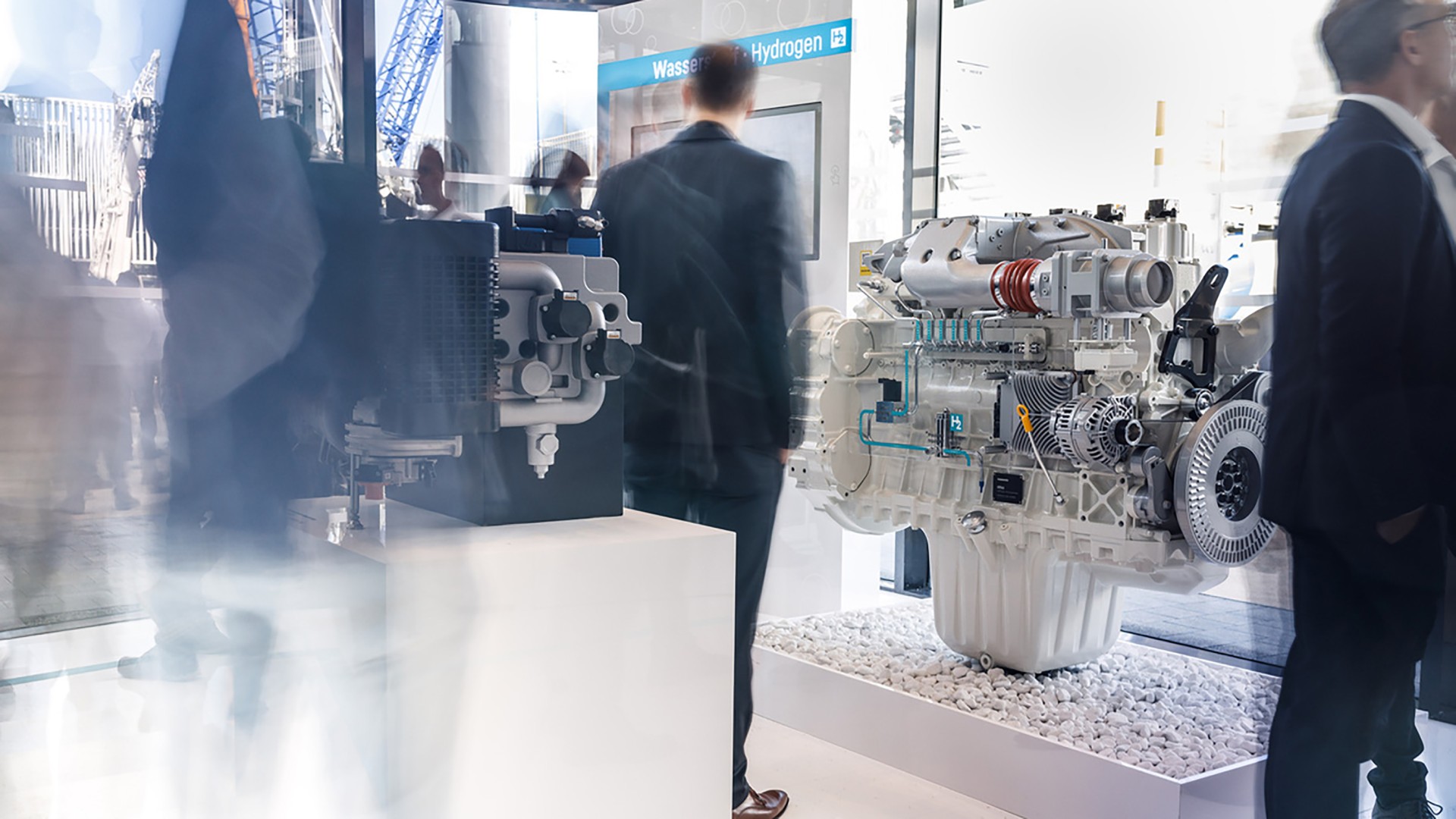

Climate protection at the touch of a button would be great. Unfortunately, however, an instant feel-good shift from fossil combustion engines to sustainable carbon-free or at least carbon-neutral drives is still a long way off, especially for certain types of construction machinery. “A compact wheel loader for horticultural use will have different requirements than a 100-ton crawler excavator used in mining sites at altitudes of 5,000 m in the Andes. In other words, developing drive concepts calls for a great many and different skills,” says Jürgen Appel, head of technology coordination at Liebherr-International AG.

Future to the power of three

Liebherr is pursuing a three-part approach to its technology:

1. Increasing the efficiency of existing drive systems

2. Electrification

3. Alternative fuels for combustion engines

Liebherr’s path to the energy transition

Liebherr equipment and components are playing an important role in the global transition to a decarbonised economy. The Group’s contributions include ship and mobile cranes for the construction of offshore and onshore wind farms, construction machines for smart city and rail network expansion, or with material handling technology for recycling valuable materials.

It must be said that many of the Liebherr machines that will play a key role advancing energy transition are designed for high power requirements and continuous operation, and are therefore based on a powertrain using fossil fuels. As this makes them major emitters of CO2, Liebherr has accelerated the development of low-emission and zero-emission technologies across its wide range of products, making significant progress along the way. “In the interests of future generations, we are continuing to invest heavily in innovations that are good for our customers and the environment alike,” explains Jürgen Appel. “In doing so, we are focusing on a comprehensive increase in efficiency.”

Seeing the big picture

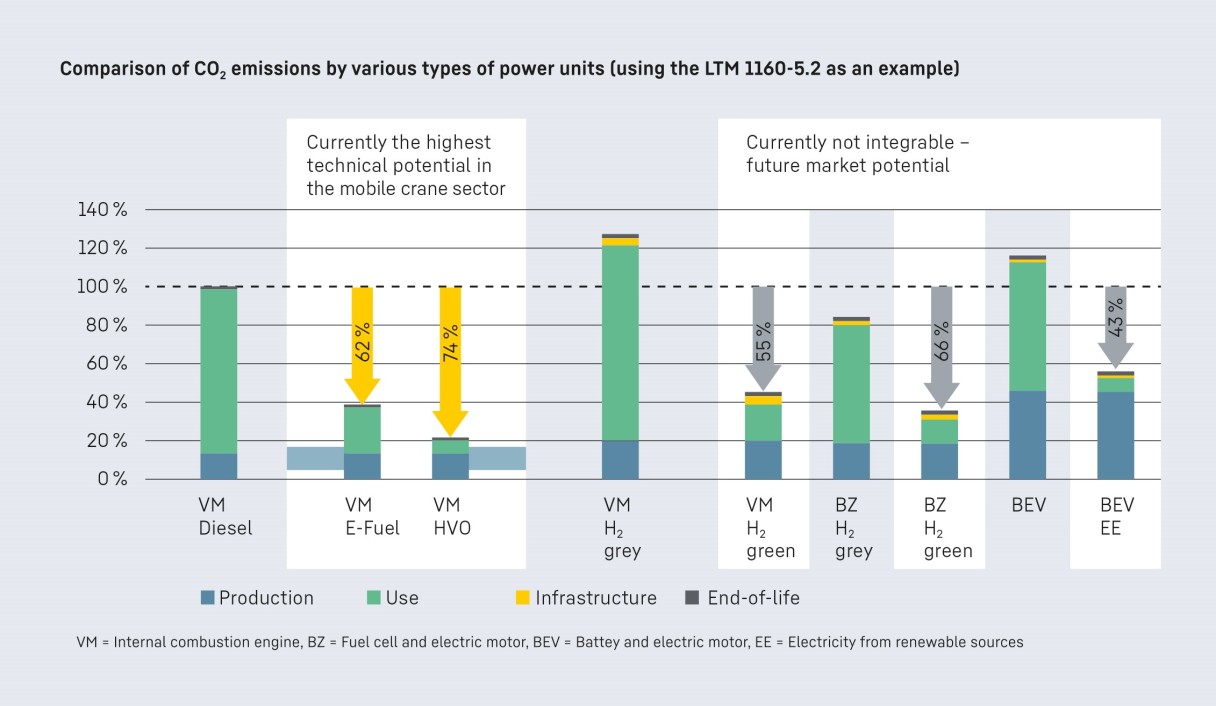

What does the carbon footprint of construction machines include? To find out, Liebherr carried out a comprehensive life-cycle analysis of the greenhouse gas emissions of standard construction machines in cooperation with business consultancy Frontier Economics. Exactly the same machine model was equipped with different drive solutions and examined. It became apparent that there is no superlative, catch-all solution for climate-neutral drive systems for construction machines.

“We can only achieve the CO2 reductions that we want and need by looking at the entire life-cycle of a machine holistically. And we can’t do if we’re closing our eyes to certain technologies from the outset. Instead, we have to concentrate on ensuring that innovative, future-proof and climate-relevant technology is presented in such a way that customers can work with it, too,” says Jürgen Appel.

Liebherr technologies with bright prospects

The Frontier Economics study has shown that holistic, life cycle-based analysis of construction machines and heavy equipment is necessary in order to achieve the climate goals laid down in the Paris Agreement. Liebherr brings together a wide range of experience and engineering skills in its central operations Corporate Technology and its own competence centers, such as our facility dedicated to batteries in Biberach and the Liebherr Digital Development Centre in Ulm.

“Liebherr isn’t just a manufacturer of machines and components, it also combines entire system competence in one place. This enables us to make advances in efficiency in all types of drives,” says Jürgen Appel. “This is invaluable for the timely and practical transition of technology.” It is always about taking a holistic perspective that encompasses both the environment and the available infrastructure: “It doesn’t make sense to develop alternatives based on renewable energies without considering their availability. Openness to technology means that our machines actually work for our customers, not least in terms of progressive climate action.”

Green electricity bottleneck

The key to lowering greenhouse gas emissions lies in the electricity generated from renewable forms of energy. It is the basis for climate-neutral electric drive systems and the production of e-fuels and “green” hydrogen. In its annual survey of energy professionals, the global classification society Det Norske Veritas (DNV) recently found that few figures in the industry (17 %) believe that the energy transition over the next decade will deliver safe, clean and affordable energy for all parts of the energy system in their country.

However, the energy industry expects higher investments in clean energy sources by as early as 2023, mainly in low-carbon hydrogen / ammonia (52 %). Wind power (49 %) and solar energy (46 %) will see a similar share in investment.

Renewables are still on the rise in Europe and the USA. In Germany, for example, they accounted for already 48.3 % of consumption in 2022 (2021: 42.7 %).

Mobile energy storage systems

The Liduro Power Port, a battery-based mobile energy storage system from Liebherr, provides electrical power for the use of all-electric or hybrid construction machines and the associated infrastructure.

“Not all construction sites have the right kind of power supply and high-performance lines, so at Liebherr we’ve looked for our own ways of transporting electricity with high energy density ourselves – even on construction sites, in order to supply machines with a wide range of performance values and peak loads on site, or to supplement existing power grids where the dimensions are too limited. That’s exactly what the Liduro Power Port from Liebherr does,” says Claus von Reibnitz, managing director of Liebherr-Electronics and Drives GmbH in Lindau (Germany).