Liebherr connects

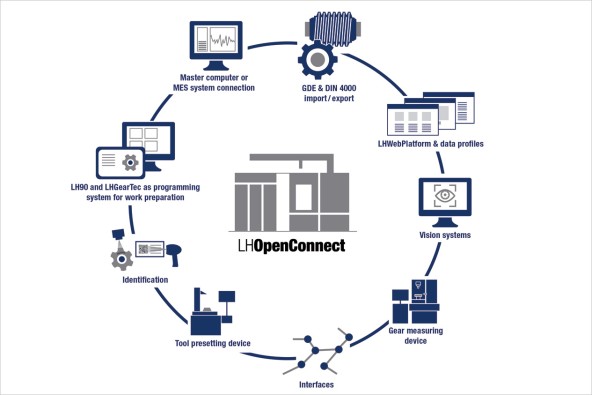

What does the name LHOpenConnect stand for? How can an open data structure help the user? Which software services does Liebherr-Verzahntechnik GmbH offer? Over the past few years, the company has gradually built up an application architecture that focuses not only on the machine, but on the entire process, which means it can support production in many different ways. Thanks to its modular structure, customers can select the tools which best complement their own specific production environment.

“LHOpenConnect is basically a complete bundle of application modules that users can put together individually,” explains Florian Schuon, Head of Preliminary Development / Industry 4.0. Examples of these are the data profiles that Liebherr provides, which can be either standard or customer-specific. Using a selection of common interfaces such as OPC UA, MT Connect and umati, the gear cutting machines can be integrated into the customer’s network, for example to exchange data with higher-level systems. “The LHWebPlatform tool is designed for visualizing the entire plant,” says Florian Schuon, presenting a brand new application. “It allows the customer to see all the machine tools at a glance – regardless of the manufacturer.”

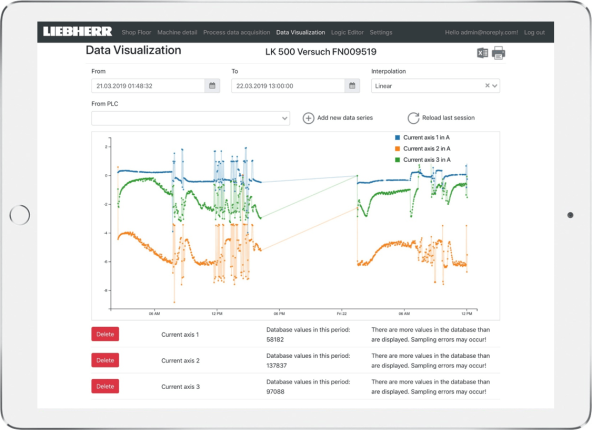

LHSignalInfo can be used for visualization. This web application can graphically display all signals from the purchased data profile and also export them for further analysis.

Visualization of the data profile with LHSignalInfo

The signals from the machines are sent to LHWebPlatform via the corresponding data profiles and stored there. “LHSignalInfo can be used for visualization. This web application can graphically display all signals from the purchased data profile and also export them for further analysis.” The data profiles are structured in three levels: Basic, Production, Process.

In total, they include over 1,000 features that can be recorded and evaluated. Users can also create their own signals in the logic editor by logically linking the standard signals and saving them in an area reserved for the customer. The LHSignalInfo then displays these freely defined signals. “For example, customers can modify the behavior of the signal lights to their factory standard without interfering with the machine programming,” says Florian Schuon. Along with the introduction of open data profiles, this is right in tune with today’s requirements.

Keeping an eye on the workpiece

The software also offers a seamless workflow for the workpiece: the geometry and manufacturing data can be conveniently parameterized on the PC, which makes preparing the work much simpler. The prepared data can then be transferred to the control system via GDE interface using the import / export function. LHOpenConnect also has an answer to the “closed loop” question. If there is a gear inspection machine, it can exchange data directly with the gear cutting machine: The measurements thus directly influence the settings and improve the result. Different labels such as QR, RFID or data matrix codes are available for identifying workpieces.

Three questions for Florian Schuon

What does LHOpenConnect aim for?

We don’t want to offer our customers a “closed” loop where they no longer have freedom – for example to transfer additional data. Instead, we want to offer our customers a comprehensive range of standard data profiles, interfaces and web applications, which can also be tailored and adapted to their individual requirements. Our goal is to make the machine as open and transparent as possible towards other production and inspection machines, control centers and data analysis systems.

So the offers go way beyond just gear cutting itself?

With LHOpenConnect, one of the many things we can do is to connect tool presetting devices directly to the gear cutting machine in order to exchange tool data in accordance with DIN 4000. Furthermore, we can connect to the measuring machine via GDE (GearDataExchange), and we can also connect work preparation programming stations to control panels, ERP systems and the machines using LHOpenConnect. Although our core area of expertise is still the gear cutting process, the applications of the LHWebPlatform and the connection options of the LHOpenConnect strategy open us up to higher-level systems and other machines on the shop floor. This means we can flexibly integrate our services and act as a system provider.

How important is LHOpenConnect for gear technology?

In addition to our core business of manufacturing gear cutting machines, LHOpenConnect enables us to establish another area of business by offering services. Nobody can integrate our machines into production processes as well as we can. Due to our own production we have also dealt extensively with machines and control systems from other manufacturers. On top of this comes our expertise in manufacturing automation cells and lines. We want to offer our customers this expertise in fully integrating manufacturing systems systematically and according to requirements – not only in the context of selling machines, but also as an additional range of services based on this.