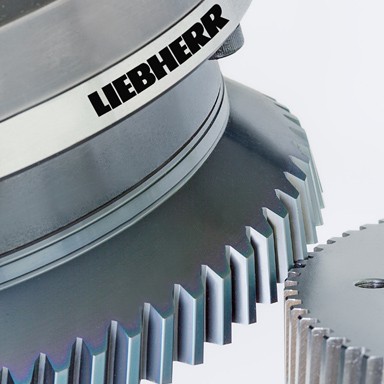

Liebherr presents the latest member in the PHS Allround family, the PHS 800 Allround. It has a narrower design than the PHS 1500 Allround, which makes it ideal for automated loading of smaller machine tools while retaining the basic principle of modular design and universal applicability and expandability.