Click RELEASE VIDEO and follow the data protection notices.

BluRoX: Innovative vacuum insulation with perlite

The future is circular

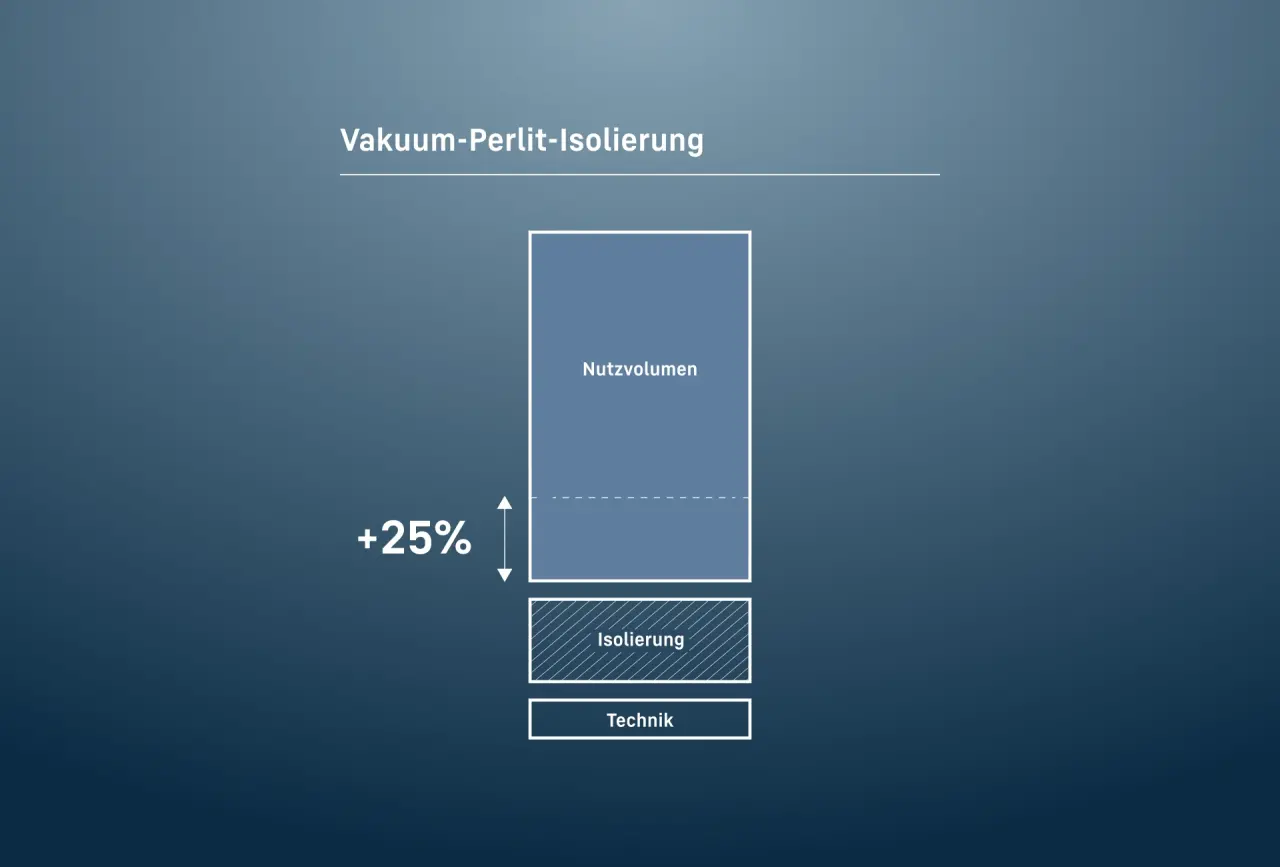

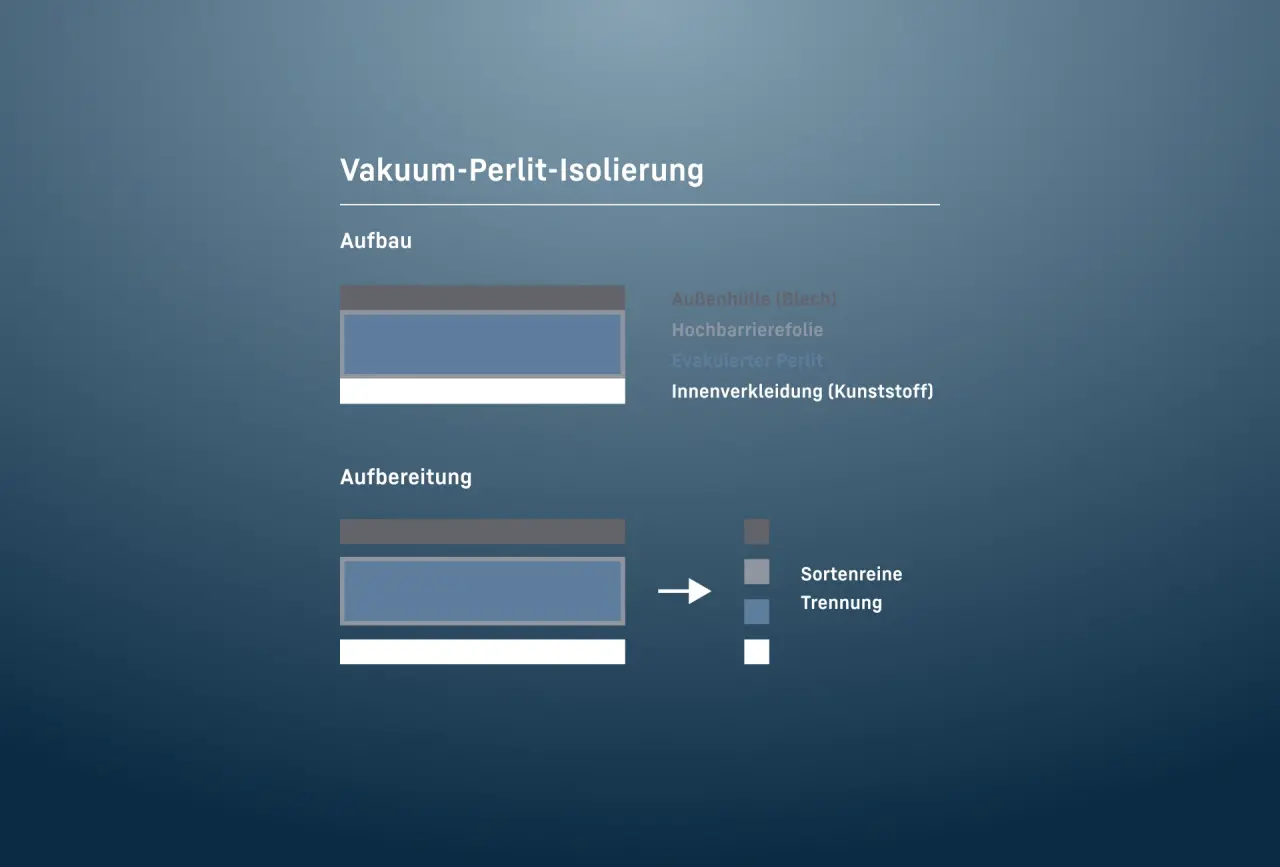

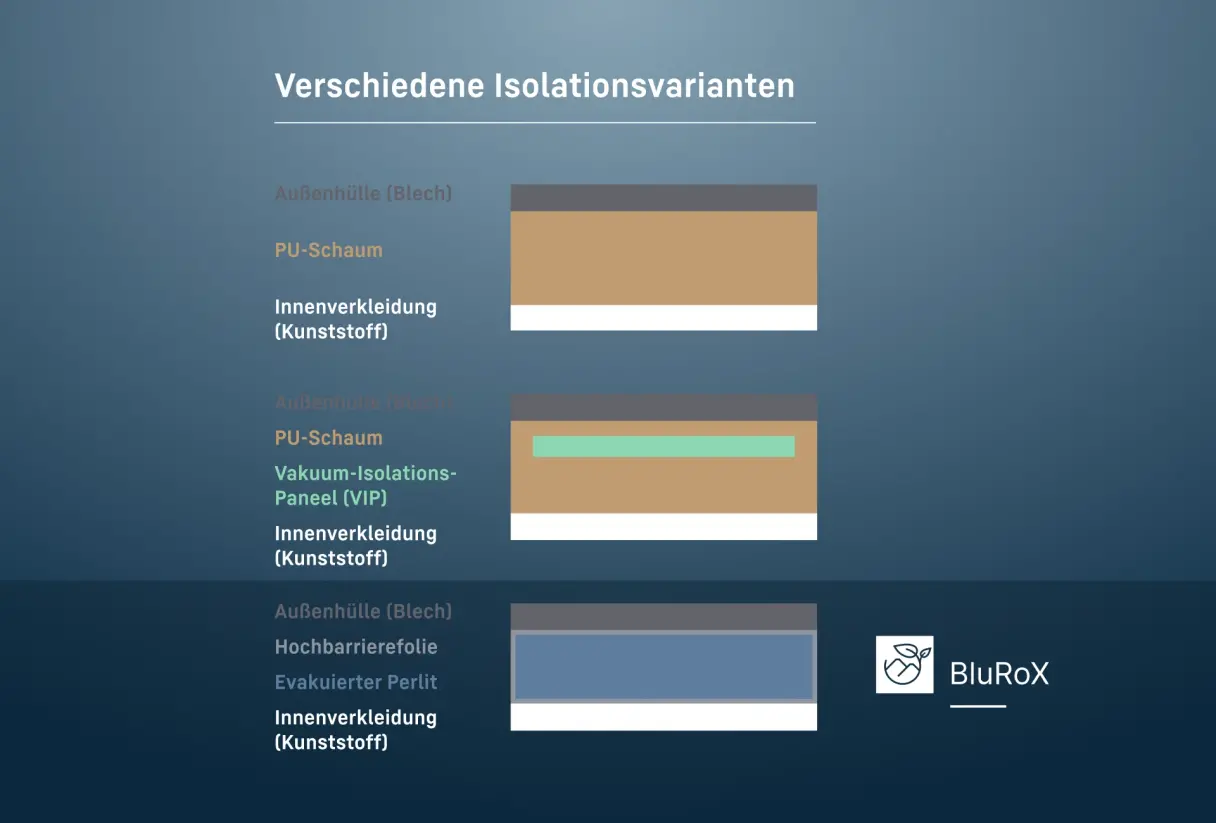

Our vacuum perlite technology is an innovation that will transform refrigeration and freezing. Introducing BluRoX. Instead of conventional polyurethane (PU) foam, this innovative technology uses a more effective form of cold insulation: a vacuum. Finely ground lava stone, known as perlite, stabilises the vacuumed components.

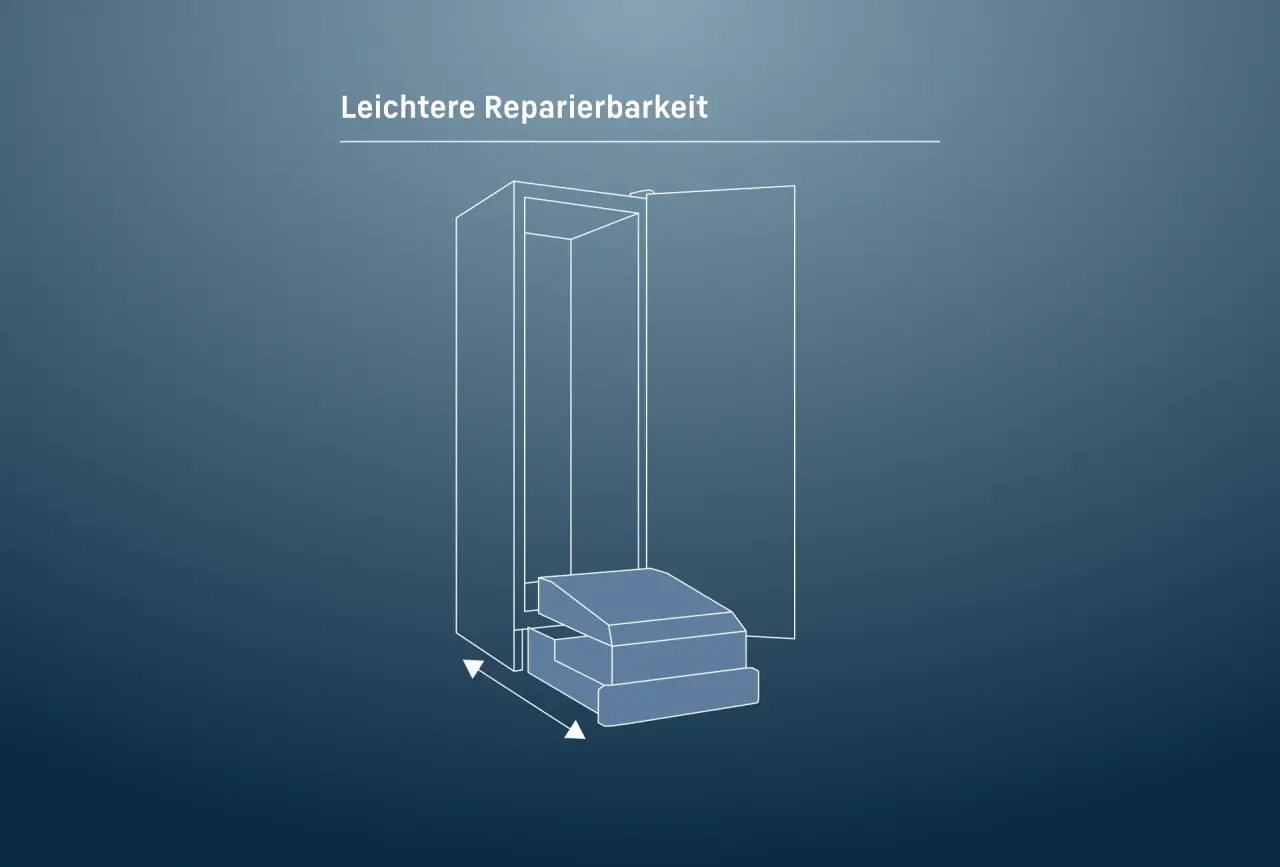

The basis: a revolutionary product design

Unlike the familiar vacuum insulation system with vacuum panels inside foam elements, the vacuum perlite technology in BluRoX appliances consists of a complete, stable 3D vacuum element.

About EcoVadis

We use EcoVadis to quantify our progress in the areas of corporate responsibility and sustainability. Our commitment to a holistic corporate strategy has now been rewarded: The EcoVadis gold medal and our position in the top 3% of all the award-winning companies makes it clear that we are facing up to ecological, social and ethical challenges.

Made in Germany

Our superior products offer premium quality, cutting edge design, and innovative features that best fit your lifestyle. The use of high quality materials, perfectly detailed finishes, and elite cooling components are combined with the latest production processes, resulting in an outstanding cooling product.

CO2 emissions (2022)

| Scope 1: | |

| Direct greenhouse gas emissions generated locally by the activities that an organisation owns or controls. | 1,428t CO2 eq. |

| Scope 2 | |

| Indirect greenhouse gas emissions resulting from purchased energy. | 0t CO2 eq. |

Water consumption (2022)

| Total annual withdrawal (2022) | 12,319 m³ | Third-party fresh water. |

| Total annual discharge (2022) | 11,683 m³ | Discharge to third-party (without onsite pre-treatment) - only applies to the water use for hygienic purposes (toilets, hand washing) and/or in kitchens. |

| Total annual consumption (2022) | 636 m³ | The water contained in the painting system* is cleaned, evaporated and put back into circulation. Fresh water needs to be added from time to time to compensate the evaporated water - the system operates without wastewater. *The painting system is not part of the production process of all BlueRoX appliances -and will be phased out for all production processes at the complete production facility. |

| Water quantity by use cycle stage of BluRoX appliances | No water consumption in manufacturing-processes of BluRoX appliances. No water consumption in use stage. | |

| Physical risk Ochsenhausen: (Baseline water stress) | medium-high (20-40%) | Reference: AQUEDUCT Water Risk Atlas |

Materials

Materials used in refrigerators and freezers come into contact with food and must therefore meet specific criteria. At Liebherr, we ensure compliance with food safety standards.

We are committed to continuously increasing the proportion of recycled materials in the future.

Where do we stand?

Currently, we are unable to procure sufficient quantities of recycled materials for plastics and glass that meet these requirements. In the case of steel, the recycled content could not be reliably demonstrated by our suppliers.

Do you have any questions or would you like some advice?

Are you looking for a new fridge or freezer? Just tell us what is important to you and we will find the right model to suit your needs. Do you already have one of our fridges or freezers and would like some advice on use and handling? Get in touch with us. We will be happy to assist you.

You can reach us by telephone from Monday to Friday between 8.00 a.m. and 7.00 p.m. On Saturdays, Sundays and public holidays, we are available from 9.00 a.m. to 2.00 p.m.

Service hotline

+43 50809 21700