Decarbonisation

Decarbonisation

We are developing innovative new technologies to help our customers make zero emission mining on their sites a reality. There is no one-size-fits-all approach to decarbonising mine sites. As such, we are committed to developing a range of energy-agnostic options that can provide customised solutions for each mine to meet their emissions reduction targets.

Agnostic and upgradable: the Liebherr Mining approach

Energy, powertrain and application agnostic

Modular solutions that can be upgraded or retrofitted

In-house core competencies

Liebherr's Zero Emission Mining Program

Our energy-agnostic decarbonisation solutions form part of Liebherr’s Zero Emission Mining Program. We are committed to meeting three decarbonisation targets within the Program:

By 2022, offer low-carbon solutions for Liebherr Mining’s full range of hydraulic excavators and off-highway trucks.

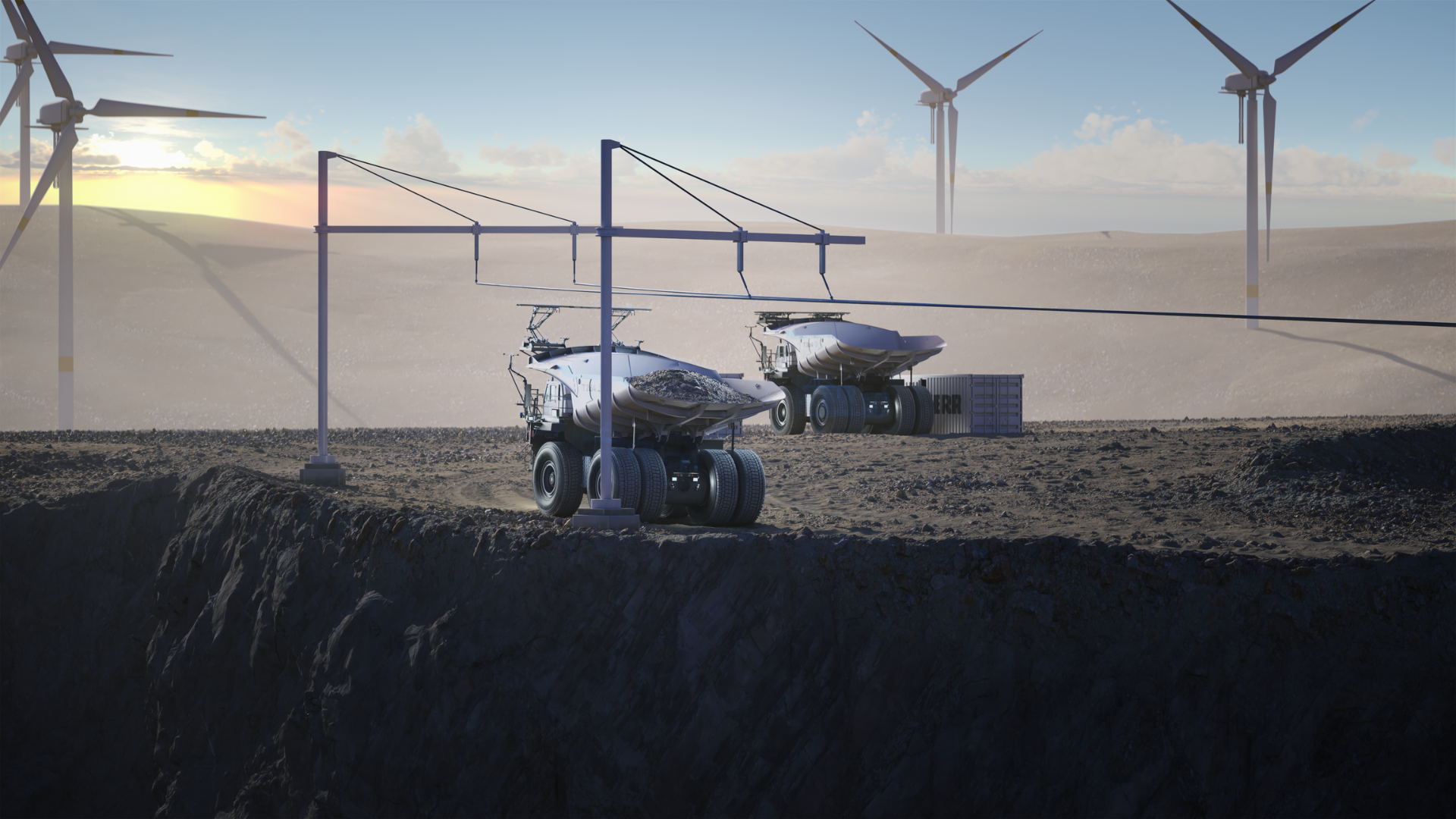

Today, we offer a range of low-carbon solutions for our excavators and off-highway trucks to help customers take their first steps towards decarbonisation. Our trucks and excavators can both run on hydrotreated vegetable oil (HVO) and are available with Tier 4 final engines, providing significant reductions in greenhouse gas, nitrogen oxide, and particulate emissions. All of our mining excavators from Generation 7 onwards come with our proprietary engine and hydraulic management systems – Liebherr Power Efficiency – as standard, which can reduce fuel consumption by up to 20% without compromising the machine's performance. And all of our off-highway trucks are compatible with the Liebherr Trolley Assist System, which connects a truck’s drive system to a mine’s power grid, subsequently reducing fuel consumption and facilitating increased productivity through faster speed on grade.

By 2030, offer fossil fuel free solutions for all Liebherr Mining products.

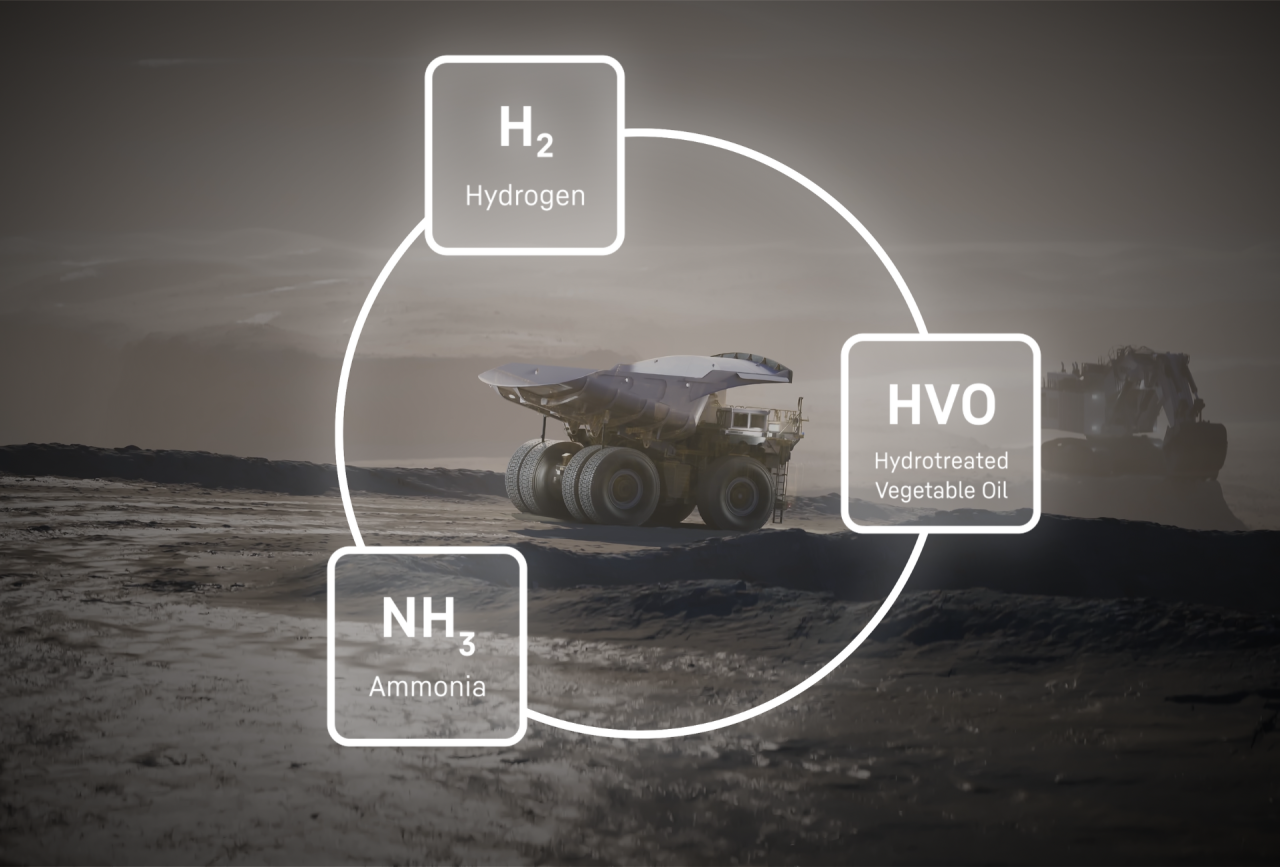

We aim to have fossil fuel free alternatives for all of our machines by 2030. We have offered customers electric-drive excavators for more than 40 years and, with our cable reel solution, these machines maintain their flexibility and manoeuvrability on site. For our trucks, we are investigating a number of options for propulsion systems to achieve zero emission operations: battery electrification, fuel cell electrification, and internal combustion engines powered by hydrogen or hydrogen carriers such as green ammonia. We are working with industry partners to examine the viability of each option. We are also investigating how equipment purchased today can be upgraded or repowered to the zero emission drive option best suited for each customer’s operations in the future.

Facilitate the reduction of emissions, taking the entire value chain into account.

The third objective targets carbon reduction for Scope 1 and 2, and relevant Scope 3 categories other than Scope 3 Category 11. This will be defined at the Liebherr Group level. In 2022, the Liebherr Group published its corporate responsibility policy, which summarised the Group’s responsibility towards both people and the environment. This policy defined the Group’s objectives and commitments for social responsibility, sustainable business management, health, safety and the environment. As part of the corporate responsibility policy, the Group is currently conducting a business-wide analysis of the emissions of its diversified product portfolio and will publish information in 2024.

Liebherr Mining’s decarbonisation history

Since delivering our first electric excavator in 1981, we have been at the forefront of innovation in reducing greenhouse gas emissions across the industry. From early electric solutions to exciting hydrogen-powered technologies, our commitment to decarbonisation spans decades of continuous progress. Explore the milestones that have shaped our path toward a more sustainable future as we strive to offer fossil fuel free solutions for all our mining equipment by 2030.

- 1981

- 1989

- 2000

- 2018

- 2019

- 2020

- 2021

- 2022

- 2023

- 2024

- 2030

Since delivering our first electric excavator in 1981, we have been at the forefront of innovation in reducing greenhouse gas emissions across the industry. From early electric solutions to exciting hydrogen-powered technologies, our commitment to decarbonisation spans decades of continuous progress. Explore the milestones that have shaped our path toward a more sustainable future as we strive to offer fossil fuel free solutions for all our mining equipment by 2030.

Since delivering our first electric excavator in 1981, we have been at the forefront of innovation in reducing greenhouse gas emissions across the industry. From early electric solutions to exciting hydrogen-powered technologies, our commitment to decarbonisation spans decades of continuous progress. Explore the milestones that have shaped our path toward a more sustainable future as we strive to offer fossil fuel free solutions for all our mining equipment by 2030.