Group

Group

Drive technologies

Drive technologies

One destination and many paths to get there

Through the systematic defossilisation of drive systems for construction machinery, cranes and mining equipment, Liebherr has its own emissions targets firmly in its sights, and those of its customers, too. The only way to reach these targets is via a path that embraces technology-neutral approaches. After all, due to the wide spectrum of applications and areas of use of Liebherr machines, there is not simply one solution.

The drive is more than just the ‘engine’ of a machine. It conceals inside it the complex system of converting and transferring energy within a machine. For combustion-based drives, this is true not only of combustion engines, but also gearboxes, hydraulic pumps, valves and hydraulic cylinders; in the case of electric drives, the electric motors, batteries and performance electronics.

When it comes to drive technology, the development departments at Liebherr have a clear goal in their sights – to provide the optimum solution for the area of application in question. Liebherr has defined four relevant pillars for technology-neutral research and development surrounding drive technologies, which are based on external conditions to varying degrees. These pillars are: the potential of a technology to reduce greenhouse gas emissions, the available infrastructure, the technological maturity and economic factors.

The four pillars of alternative drives

Liebherr has conducted extensive studies, including with the support of external scientific expertise, to calculate the carbon footprint of selected products. These studies took into account the entire life cycle of the products – from resourcing the raw materials and manufacturing the products, through to customer usage and, ultimately, disposal at the end of its useful life. The findings: the majority of the emissions come from the actual operation of the machine. Depending on the type of machine and the purpose of its use, different drives make the greatest difference in terms of hitting emission targets. In light of this, Liebherr adopts a technology-neutral approach and focuses its development on a variety of technologies.

Drive systems at Liebherr

- HVO

- E-fuels

- Grid-connected electric machines

- Battery-operated machinery

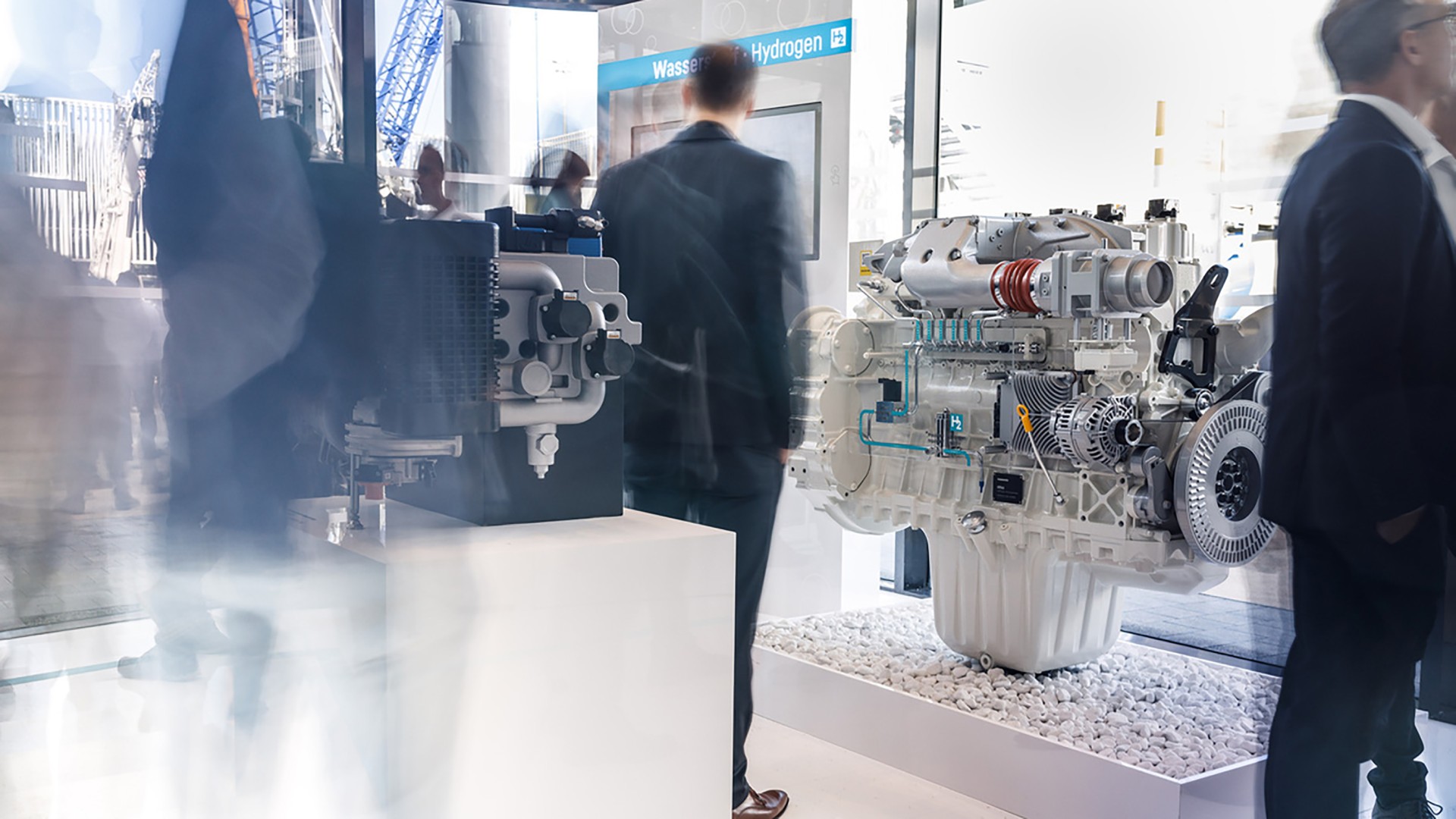

- Hydrogen engine

- Hydrogen fuel cell

- Ammonia

- Hybrid drive systems

- Fossil diesel

HVO

HVO (hydrotreated vegetable oil) is already established as an alternative energy source, since – like many other e-fuels – it can already be used in a large number of Liebherr machines with conventional combustion engines. Liebherr is already delivering a large proportion of its machines with conventional combustion engines in HVO-ready versions. HVO serves as an alternative to diesel and has the advantage that it does not contain any aromatic compounds and produces fewer emissions than fossil-derived diesel. Nevertheless, given the availability of raw materials, HVO is unlikely to completely replace diesel and kerosene.

HVO

HVO (hydrotreated vegetable oil) is already established as an alternative energy source, since – like many other e-fuels – it can already be used in a large number of Liebherr machines with conventional combustion engines. Liebherr is already delivering a large proportion of its machines with conventional combustion engines in HVO-ready versions. HVO serves as an alternative to diesel and has the advantage that it does not contain any aromatic compounds and produces fewer emissions than fossil-derived diesel. Nevertheless, given the availability of raw materials, HVO is unlikely to completely replace diesel and kerosene.