Aerospace and transportation systems

Aerospace and transportation systems

About us

About us

A leading system supplier in the aerospace and transportation industry

Liebherr-Aerospace & Transportation SAS, headquartered in Toulouse (France), is one of thirteen product segments of the Liebherr Group and is a first-tier provider of on-board solutions in the aerospace and transportation industry. Liebherr is contributing to a more sustainable transport through innovative products, best in class services and performance excellence.

We follow a long-term strategy for the benefit of our customers, our employees and our community, aiming at a solid and profitable growth, whilst at the same time taking the challenge of a fundamental transformation of our operations in many aspects: We will be a key contributor to prepare the future of our industry, that will be more digital, more sustainable, and more versatile.

Alex Vlielander – Chief Customer Officer, Martin Wandel – Chief Operating Officer, François Lehmann – Chief Financial Officer, Dr. Klaus Schneider – Chief Technology Officer

Governance

Liebherr-Aerospace & Transportation SAS is the divisional control company of the Liebherr product segment aerospace and transportation, governed by the Liebherr-Aerospace & Transportation SAS Board as the top executive body.

Facts & figures 2023

Consolidated turnover: 1,500€ m

Growth rate: 14.5%

Average spendings in research & development: 15% of turnover

Employees: 6,386

Market share: among the top 3 industry players in its major product lines

Production sites: 11

Annual report

The Liebherr Group's annual report highlights key figures from the business year and details developments within individual product segments. Explore the financial statements and gain deeper insights into our overall performance and outlook.

Here you can access the annual report and also download facts and figures as a concise summary.

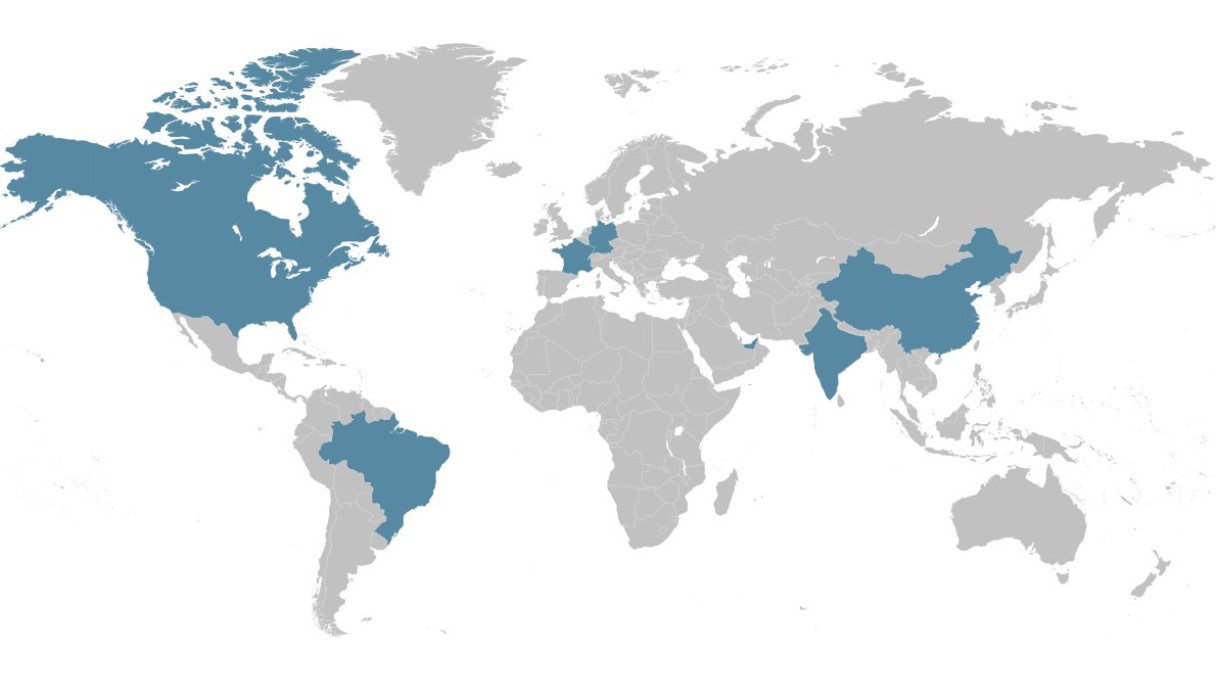

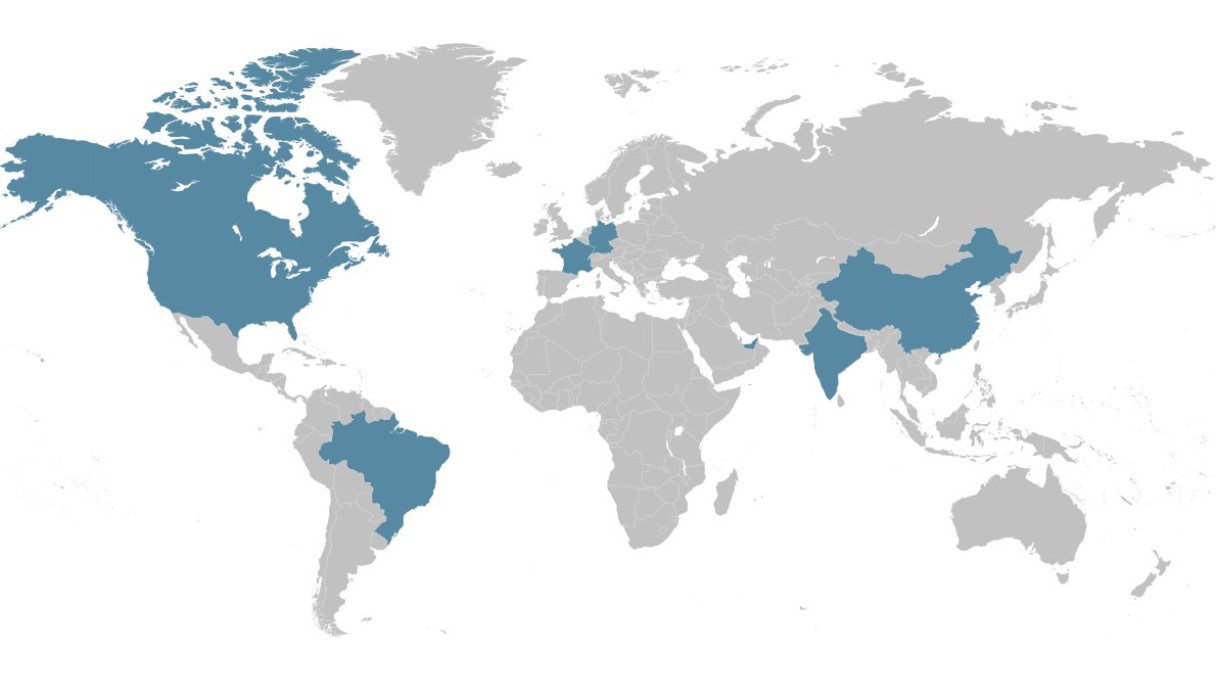

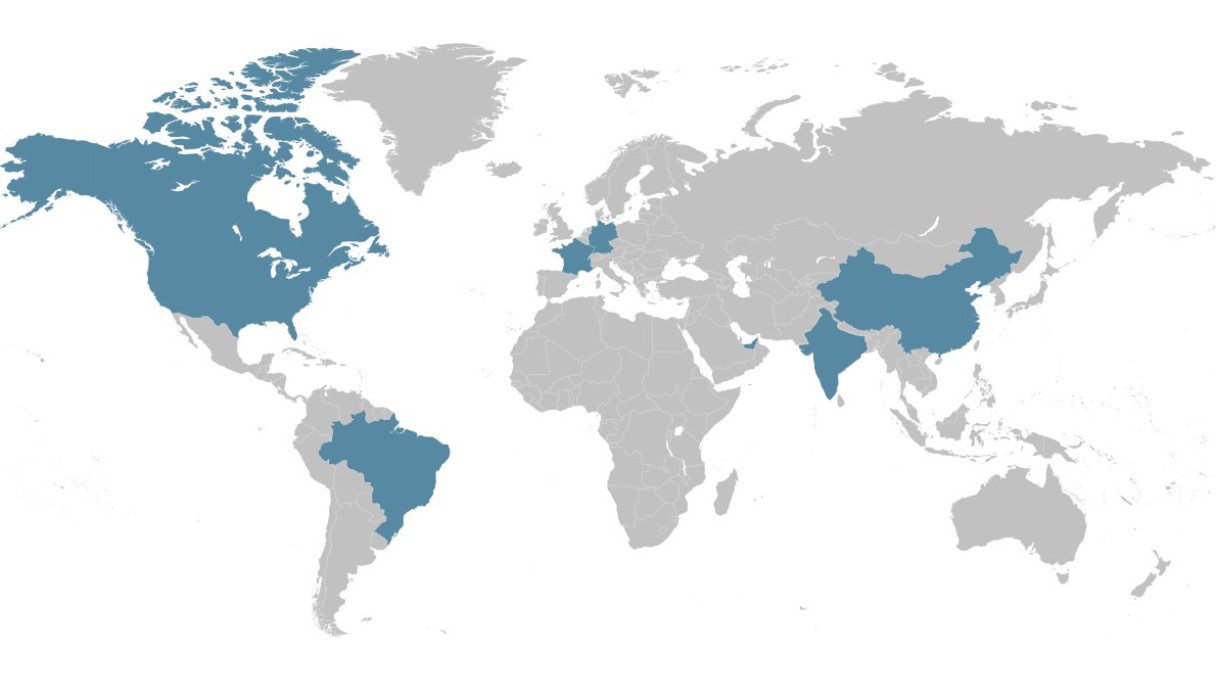

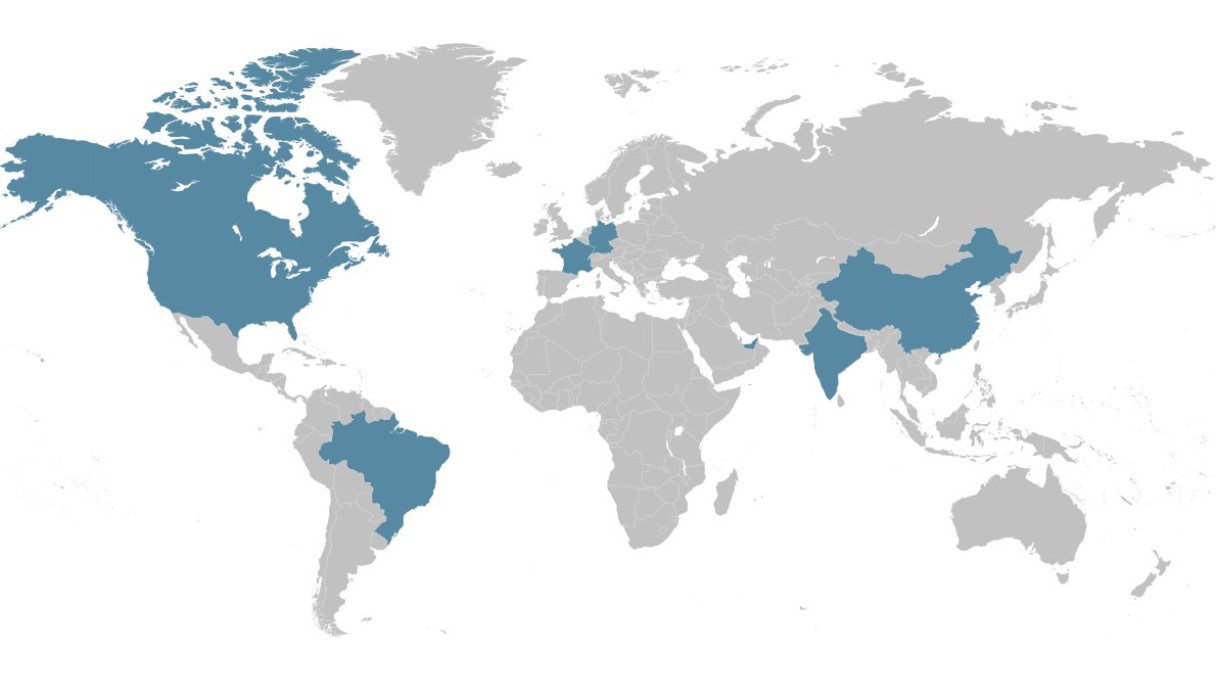

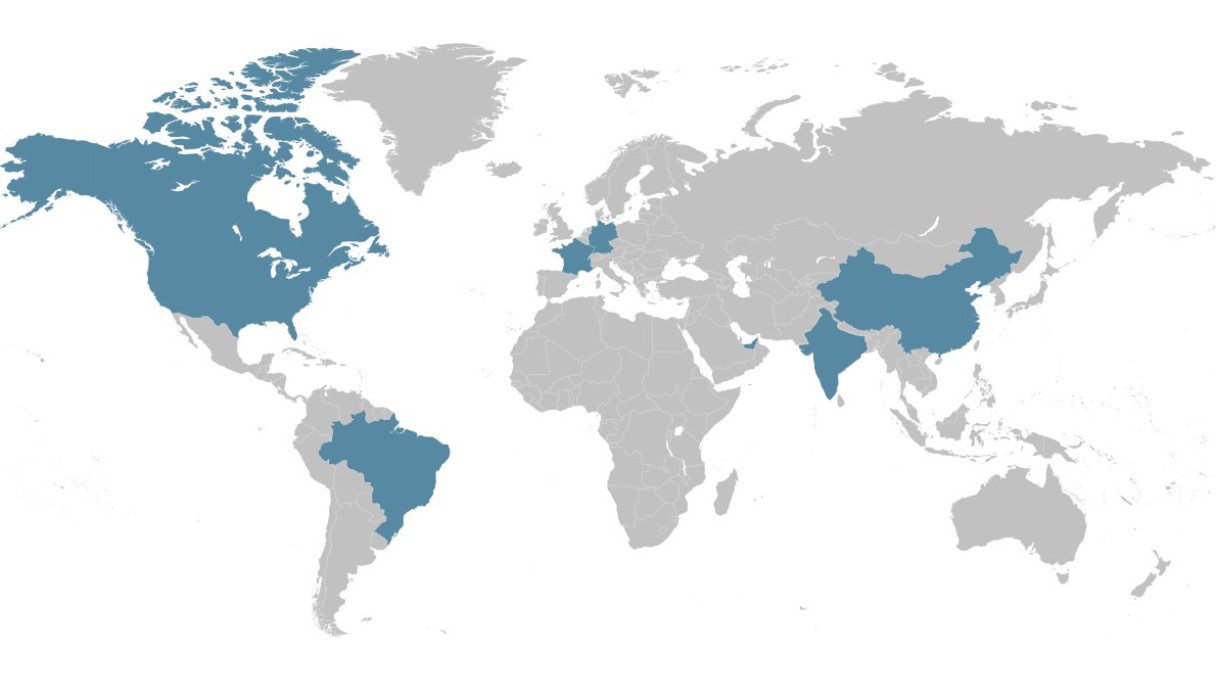

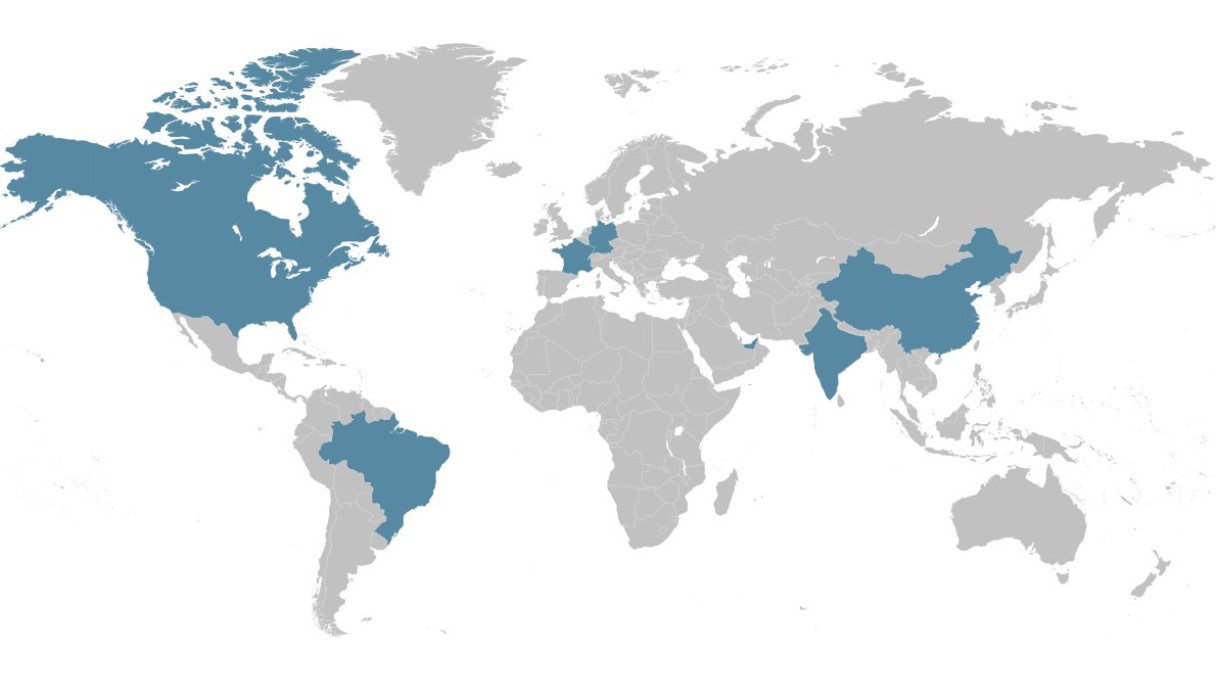

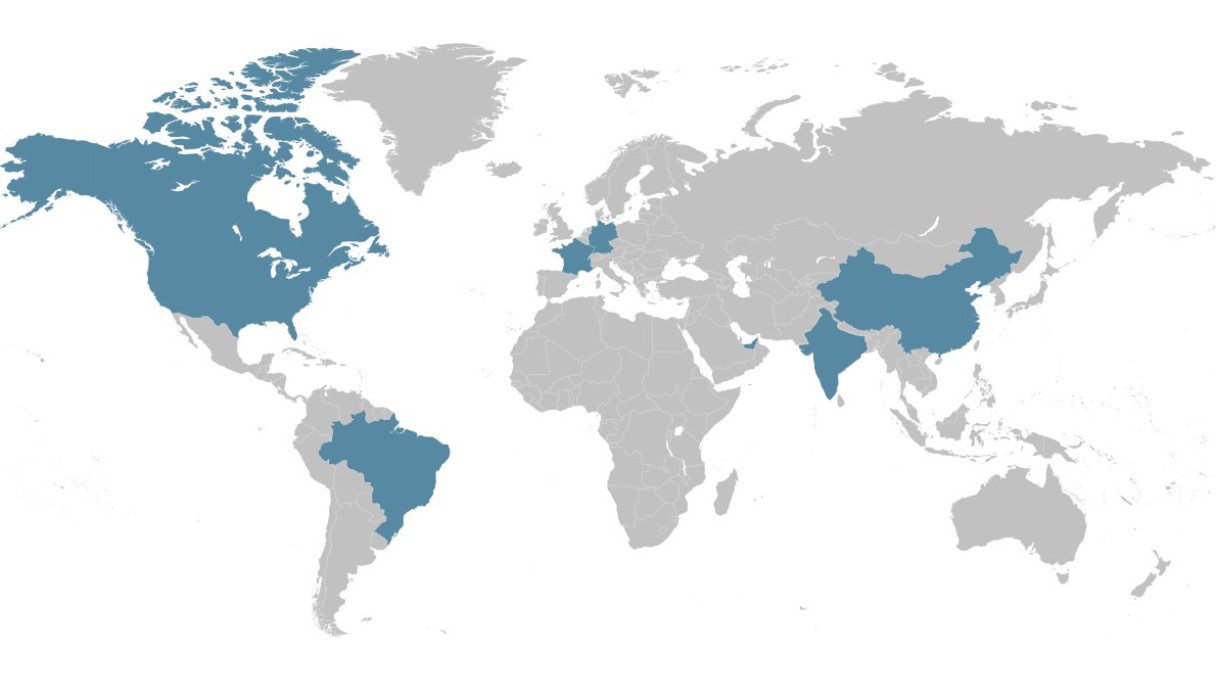

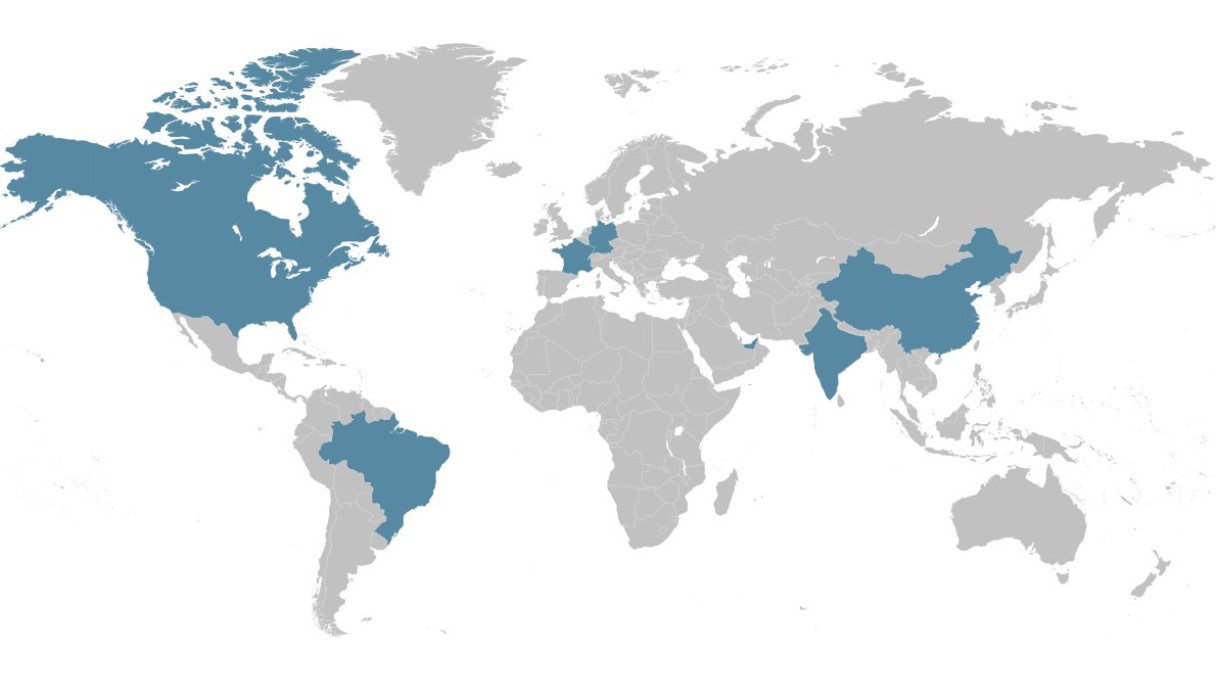

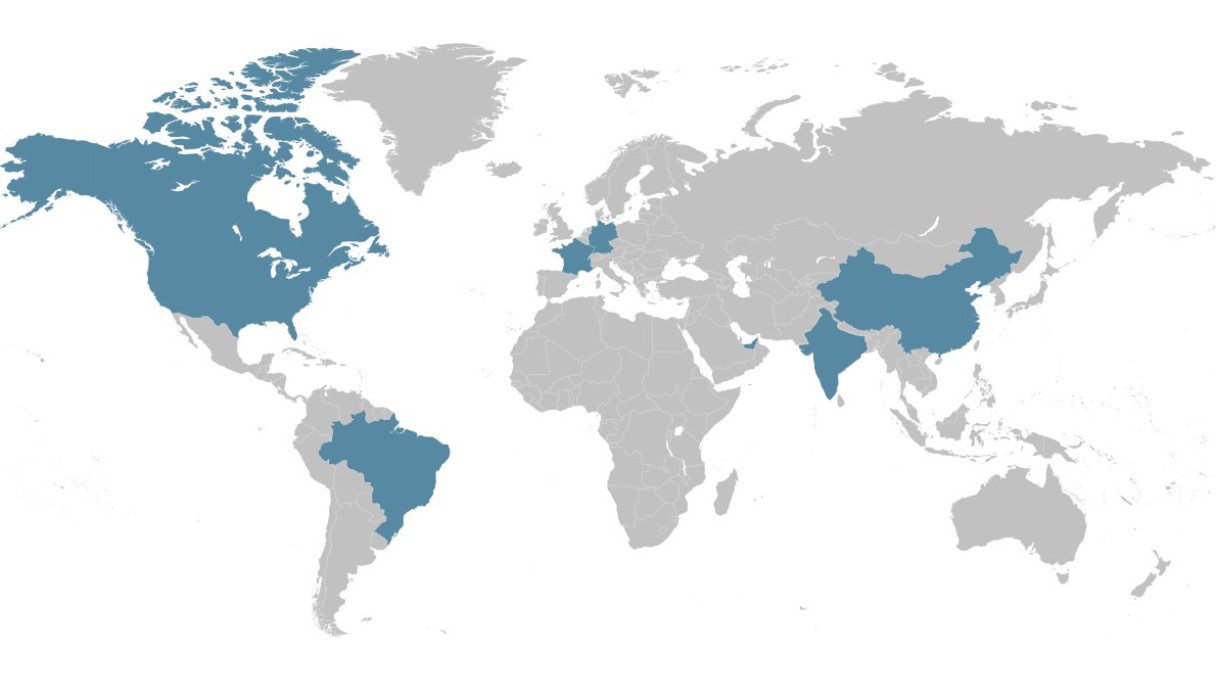

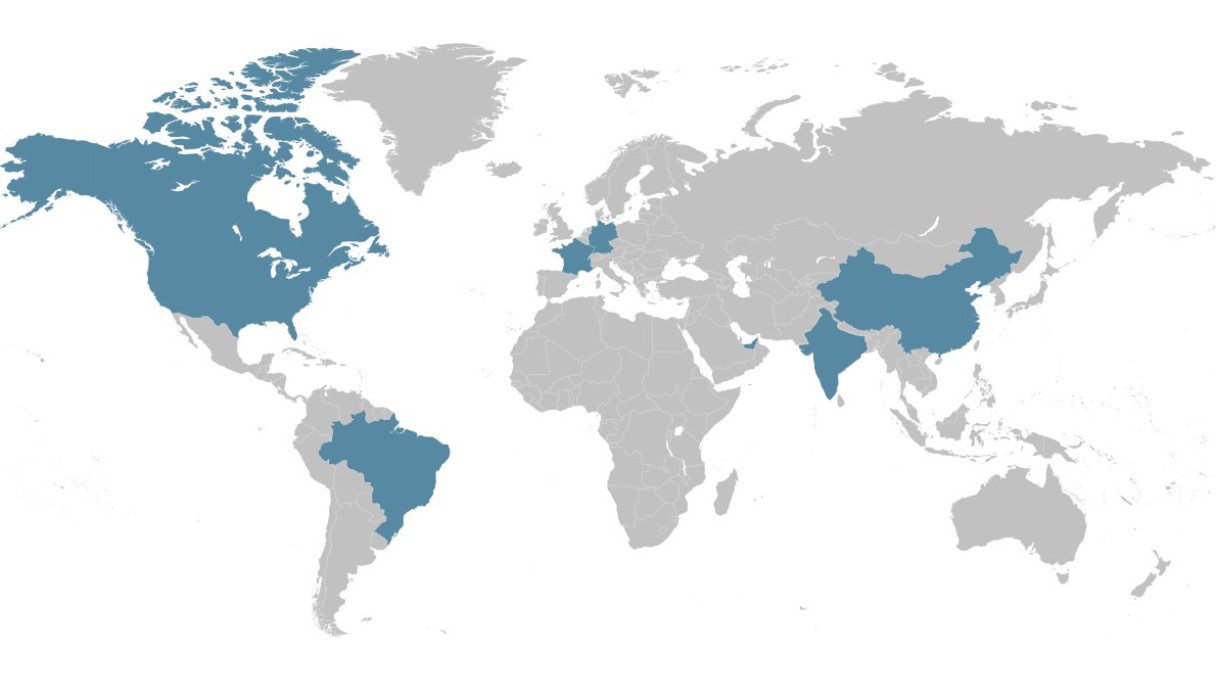

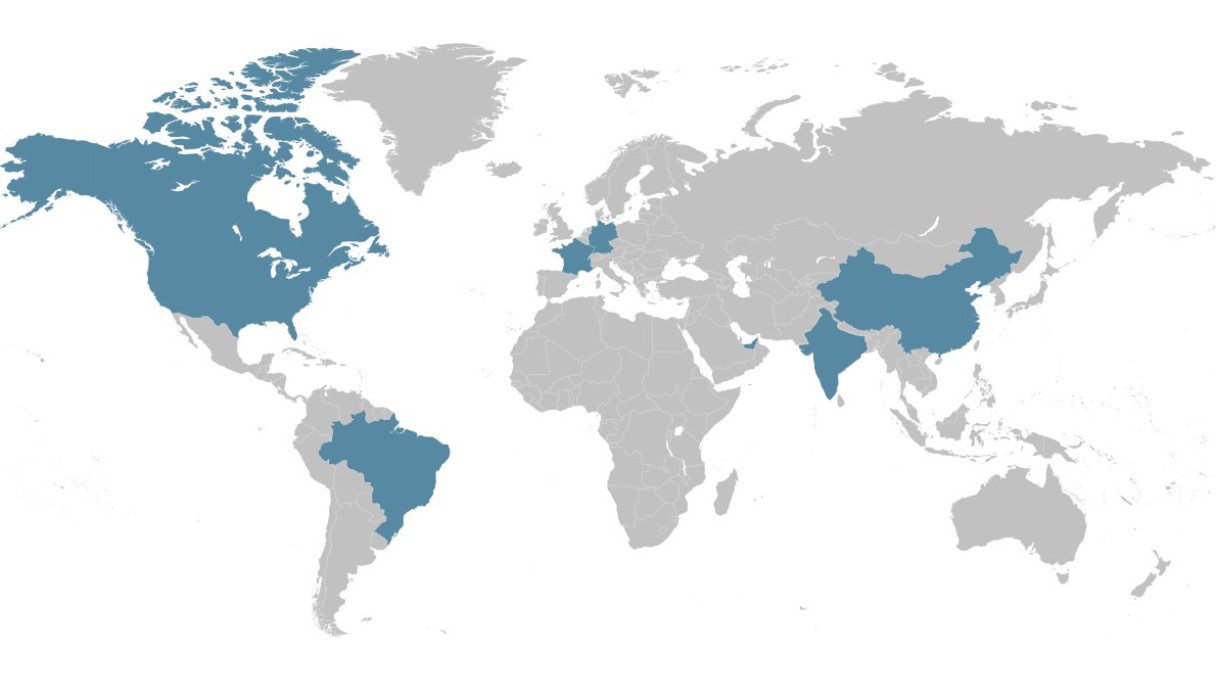

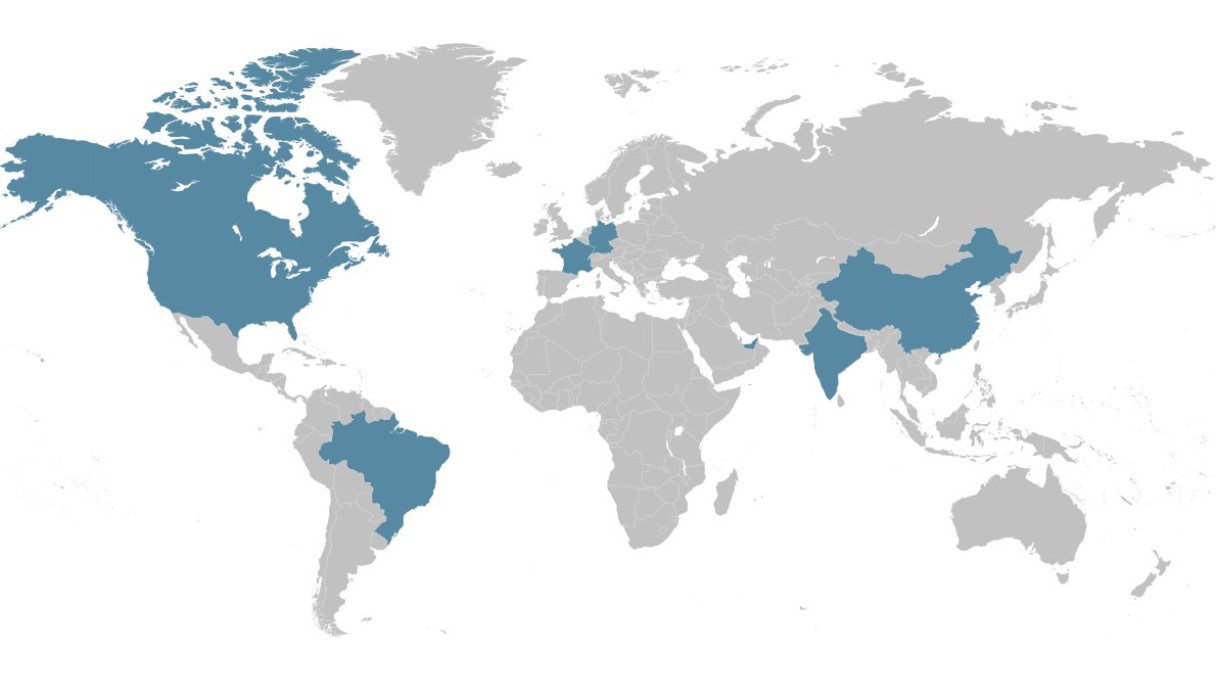

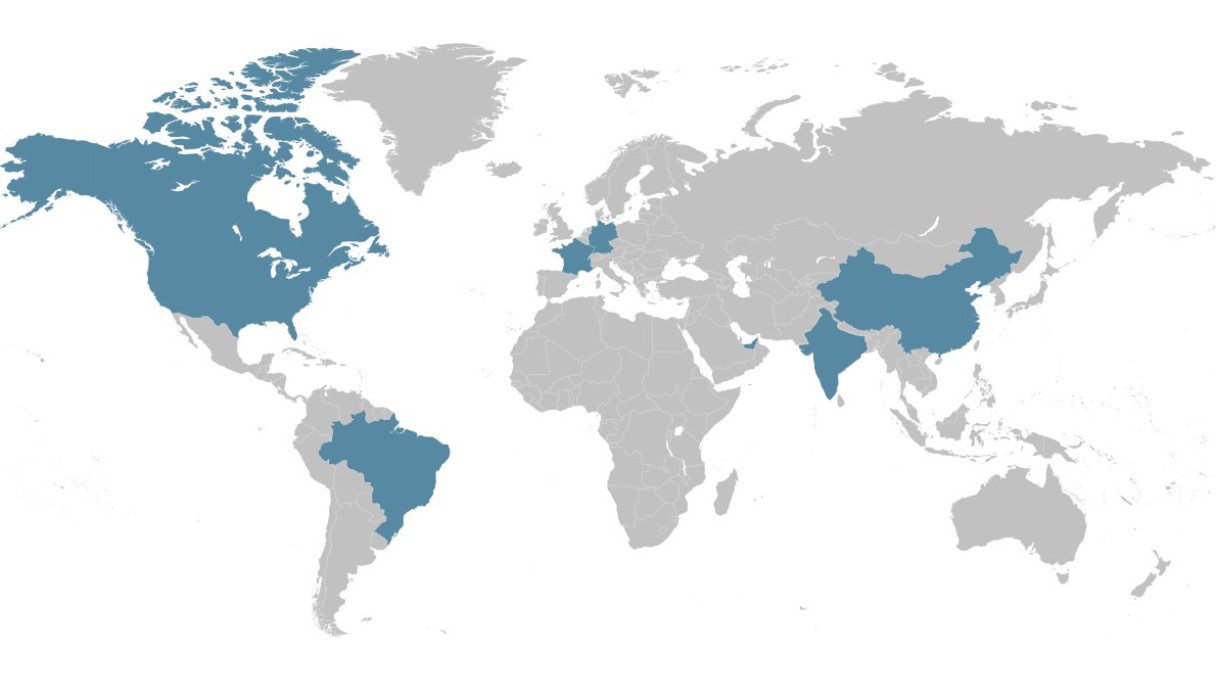

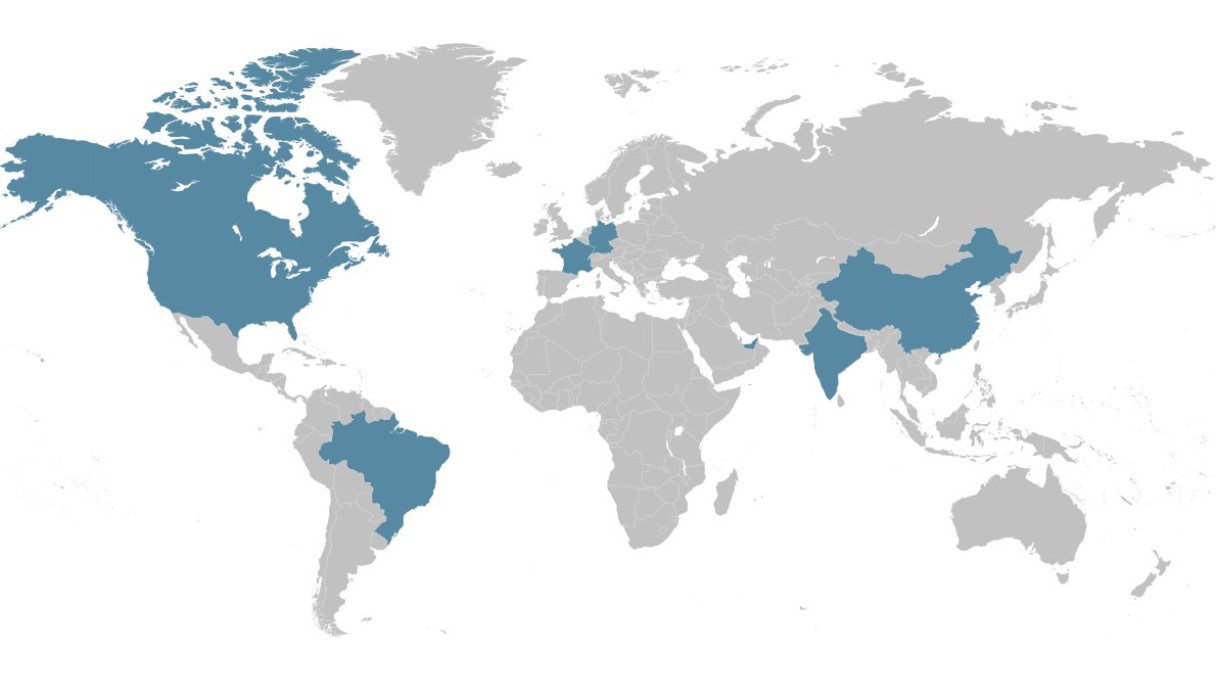

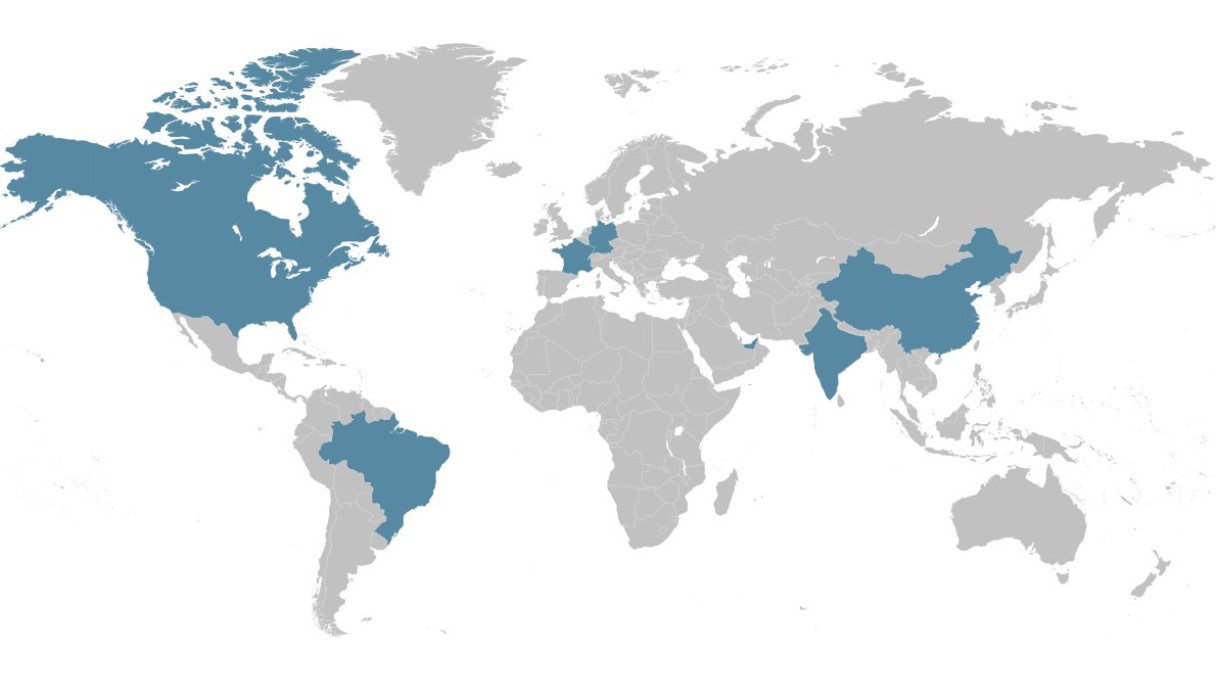

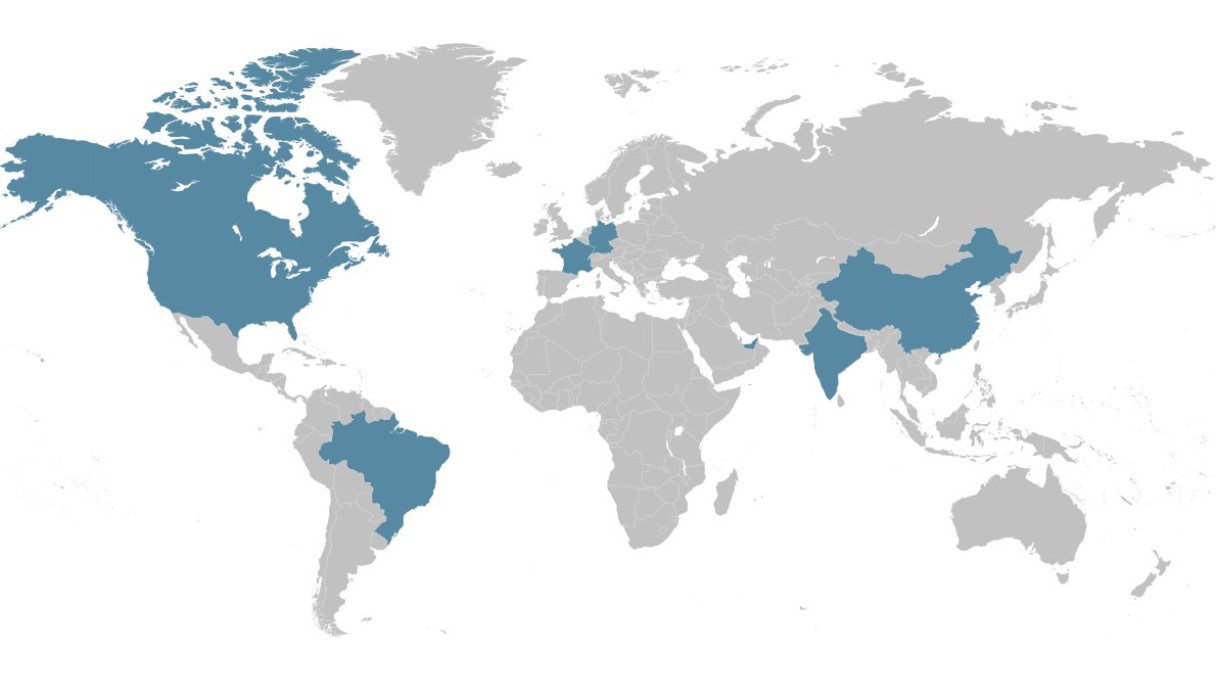

Locations around the globe

Europe

Germany

Find out more

France

Find out more

Austria

Find out more

Bulgaria

Find out more

United Kingdom

Find out more

Asia

Singapore

Find out more

United Arab Emirates

Find out more

India

Find out more

China

Find out more

Americas

Brazil

Find out more

USA

Find out more

Canada

Find out more

Visit us on social media

Customers

Being recognized by our customers for excellence in the work we do is our goal. Customer satisfaction is the compass that guides us in our long-term strategy.

In our market segments, many OEM customers and operators worldwide have entrusted us with their confidence, of which we are very proud. It illustrates our ability to contribute to their designing and building more efficient aircraft and vehicles or to their enhancing of fleet operations.

Working on the future of mobility

Are you ready for the journey?

Looking for a job in the aerospace and railway industry? Join Liebherr, a family-run company, for your next career move. We are looking for enthusiastic talents and offer many opportunities. Our core values, our sense of community and our demand for skills in various field will lay the ground for your professional career.

Get in touch

History

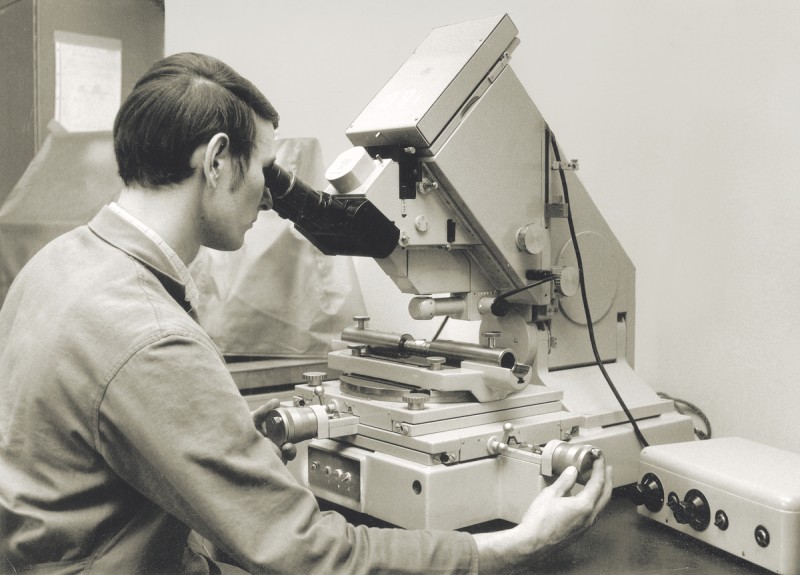

1960 - 1970

Entry into the aviation industry - maintenance and license production

Hans Liebherr, who founded the Liebherr family business in 1949 and was already well known as a manufacturer of construction machinery and refrigerators, entered the aviation industry in the year 1960.

By 1965, Liebherr-Aero-Technik GmbH had established itself as a successful license company for the manufacturing of landing gears and hydraulic equipment, but it did not develop or manufacture its own products. Hans Liebherr took the decision to develop the company from a licensee to an original equipment manufacturer (OEM) providing complete systems to the aviation industry.

In November 1969, an important milestone was reached: Liebherr-Aero-Technik and the British aviation company H.M. Hobson won the contract for the development and manufacture of the slat and flap actuation system for the new European aircraft program Airbus A300.

1970 - 1980

Technological expansion and international orientation

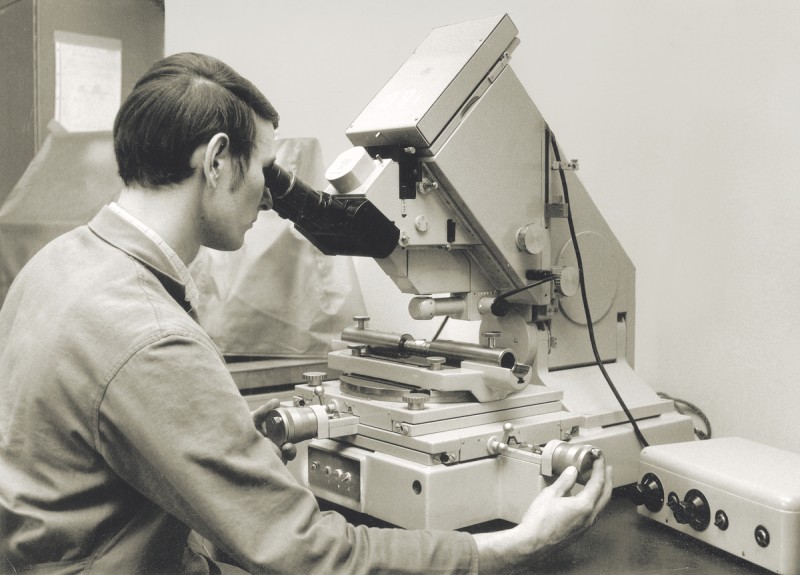

As an OEM and through cooperation with partner companies, Liebherr-Aero-Technik was able to develop its activities into new products and markets. Flight control systems and air management systems were added to the product portfolio. Technological independence was strengthened by the establishment of an own department for electronic hardware and software. Advanced technologies like fly-by-wire flight controls have been developed during this period. Major program milestones included the first contracts with Boeing for the 767 and E-3A as well as the selection for the German anti-tank helicopter PAH-1.

1980 - 1990

Among leading system providers

By the beginning of the 1980s, Liebherr-Aero-Technik had achieved some important goals: it had entered numerous international cooperations and had brought its own developed products onto the market. For the first time most of the turnover was generated through participation in civil programs.

Liebherr was selected to provide the flight control and air-conditioning system for the Airbus A320, which sold exceptionally well. As the production rate of the A320 was increased, the pace of production in Lindenberg had to be increased significantly as well. This was achieved by optimizing the efficiency of the industrial set-up and with high investments in modern machining centers.

Liebherr-Aero-Technik expanded its customer base both in the West, i.e. in the USA and Latin America, as well as in the East in countries such as Indonesia, Israel, China and Singapore.

At the end of the decade, the decision was taken to build-up own landing gear development capabilities.

1990 - 2000

Expansion

The 1990s were characterized by growth but began with an economic slump. Due to the Gulf War in 1991, air traffic and thus also the demand for aircraft declined. Liebherr-Aero-Technik overcame the crisis by reducing overtime and adjusting capacity.

The planned strategy of global growth was nevertheless pursued. Besides the organic growth, major acquisitions were adding capabilities, like ABG- SEMCA in Toulouse (France) – now called Liebherr-Aerospace Toulouse SAS - for air management, Feinmechanische Werke Mainz (Germany) for hydraulic actuation and the Friedrichshafen plant of ZF (Germany) for excellence in gear cutting.

In 1996, Liebherr-Aero-Technik GmbH changed its name to "Liebherr-Aerospace Lindenberg GmbH".

Liebherr-Aerospace also expanded its customer service: Service facilities were established in the USA, Singapore and Shanghai (China).

In 1997, Liebherr decided to step into the railway market by acquiring Alex. Friedmann GmbH (Austria), which had manufactured air-conditioning systems for rail vehicles among other things. In Korneuburg, near Vienna, Liebherr established its transportation technology branch and changed the company's name to Liebherr-Transportation Systems GmbH & Co KG. Know-how was supplied by Liebherr-Aerospace Lindenberg for the product area of hydraulic actuation systems and by Liebherr-Aerospace Toulouse for the air cycle air-conditioning technology.

In 1998, Liebherr-Aerospace G.I.E., based in Toulouse (France), was founded. The company's task: to coordinate all Liebherr activities in the field of aerospace and transportation technology.

.jpg)

2000 - 2010

Becoming a global player

In 2002, the divisional control company Liebherr-Aerospace G.I.E. in Toulouse (France) was restructured and renamed Liebherr-Aerospace & Transportation SAS.

A new production facility was opened in Brazil, and service stations were set up or expanded close to customers all over the world.

Many first flights and entries-into-service of aircraft programs within a few years demanded top performance from the employees and they delivered, thus contributing to Liebherr's success not only as an Original Equipment Manufacturer but also as an important player in the after-market.

The cooperation with the Brazilian aircraft manufacturer Embraer that started already in the 1990s, was further intensified, especially for landing gears. The joint venture ELEB was founded in 1999 to support Embraer’s needs for the ERJ 135/145 and later the E-Jet E1 regional aircraft programs.

In 2005, Liebherr took over business activities from Bombardier Transportation in Mannheim and founded the company Liebherr-Transportation Systems Mannheim GmbH, which offers a complete range of engineering and project management services along with customer support for the railway products.

The series production of HVAC systems for the railway market started 2009 at the new location Liebherr-Transportation System Marica EOOD (Bulgaria).

2010 - 2020

Continuous growth and major technical milestones

The long-term success story of Liebherr-Aerospace & Transportation SAS continued during the booming 2010s worldwide. With rapidly increasing aircraft fleets, Liebherr had to expand its production facilities as well as its customer services stations: A new surface treatment area, for example, as well as a new logistics center and a new manufacturing building were inaugurated in Toulouse (France) and Campsas (France), and a customer service logistics center was opened in Dubai (UAE). In Saline, Michigan (USA), Liebherr built a new customer service center to expand its heat transfer equipment repair capabilities.

In 2015, Boeing Commercial Airplanes selected Liebherr-Aerospace to supply the fold sub-system for the folding wing tip system of the Boeing 777X – a major milestone for both companies. Further contracts followed for the 777 and 787 platforms.

In the same year, Liebherr and Rolls-Royce agreed to establish a 50:50 joint venture called Aerospace Transmission Technologies GmbH, based in Friedrichshafen (Germany) to develop manufacturing capability and capacity for the power gearbox for Rolls- Royce’s new UltraFan® engine.

In 2017, Liebherr-Aerospace opened a new regional office in Bangalore that underlines the company’s long-term strategy to increase its presence and to enlarge its footprint in India.

Two years later, Liebherr founded a new company in Asia. Liebherr-Transportation Systems (China) Co., Ltd. is based in Pinghu and has the goal to grow Liebherr’s local ability to develop, test and manufacture state-of-the-art railway equipment in China.

The decade was also characterized by the introduction of advanced technologies, proving the companies pioneering mindset:

In the railway sector, Liebherr delivered an air cycle air-conditioning system to the French Public Railways Operator SNCF. This demonstrator was tested within the frame of SNCF’s “Eco-Clim” (“Green HVAC”) research program aimed at defining tomorrow’s train air-conditioning systems. The air-conditioning system uses only ambient, normal air and no refrigerant as a coolant.

Reduced greenhouse gas emissions as well as fuel burn reduction can be also achieved with Liebherr’s Electrical Environmental Control System (eECS) that completed successfully its first flight on board the Airbus A320 Flight Lab in 2016.

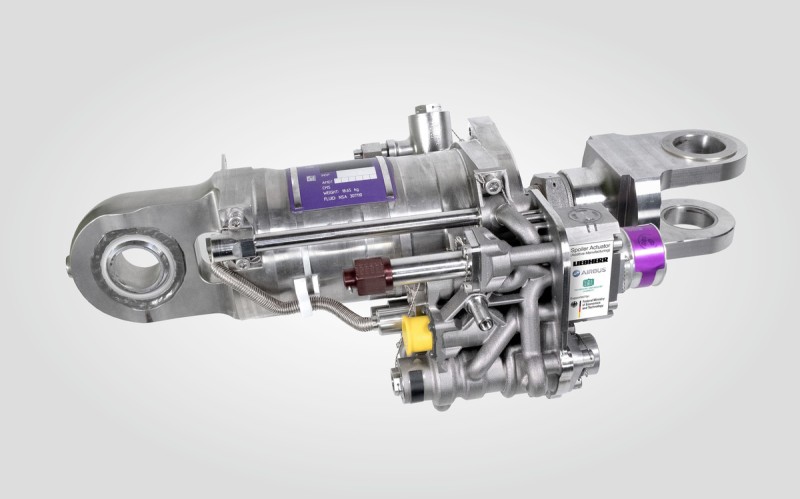

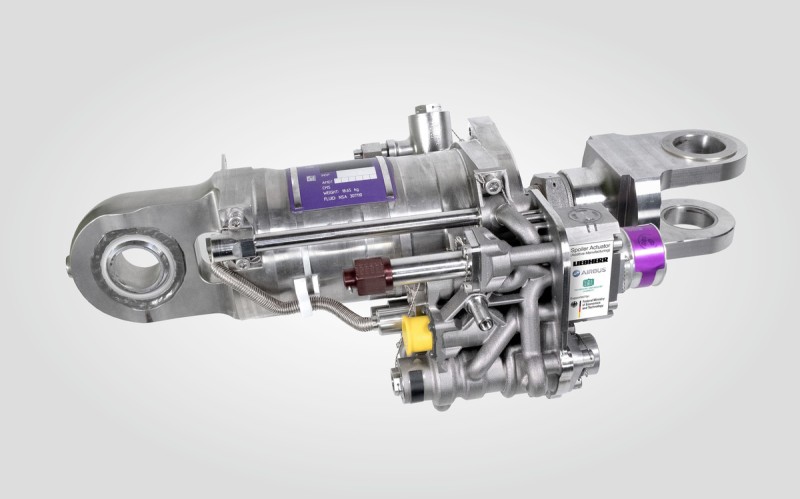

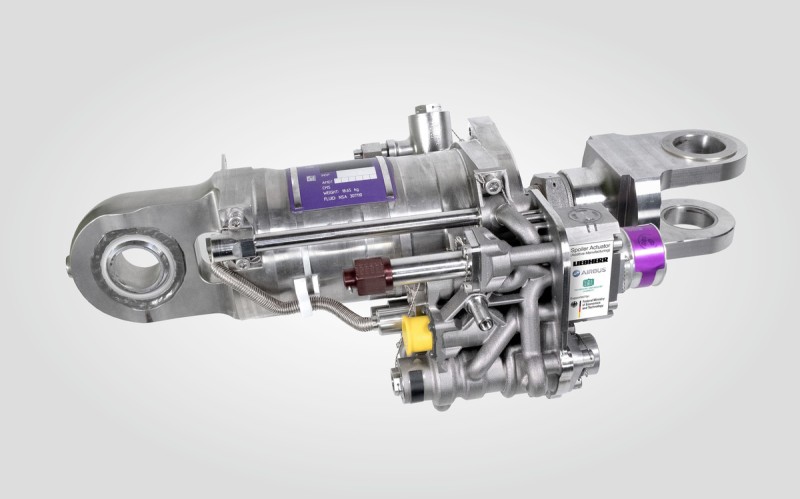

The year 2017 saw a world premier: On March 30, Airbus successfully flew Liebherr-Aerospace’s 3D printed spoiler actuator valve block on a flight test A380. It is the first 3D printed primary flight control hydraulic component flown on an Airbus aircraft. Already in 2019 Liebherr started serial production of 3D printed components for Airbus, i.e. nose landing gear brackets for the Airbus A350.

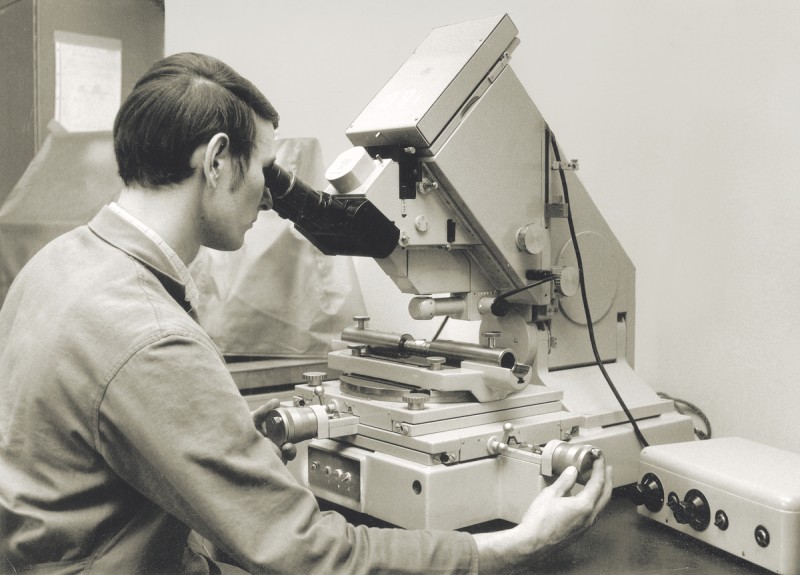

1960 - 1970

Entry into the aviation industry - maintenance and license production

Hans Liebherr, who founded the Liebherr family business in 1949 and was already well known as a manufacturer of construction machinery and refrigerators, entered the aviation industry in the year 1960.

By 1965, Liebherr-Aero-Technik GmbH had established itself as a successful license company for the manufacturing of landing gears and hydraulic equipment, but it did not develop or manufacture its own products. Hans Liebherr took the decision to develop the company from a licensee to an original equipment manufacturer (OEM) providing complete systems to the aviation industry.

In November 1969, an important milestone was reached: Liebherr-Aero-Technik and the British aviation company H.M. Hobson won the contract for the development and manufacture of the slat and flap actuation system for the new European aircraft program Airbus A300.

1970 - 1980

Technological expansion and international orientation

As an OEM and through cooperation with partner companies, Liebherr-Aero-Technik was able to develop its activities into new products and markets. Flight control systems and air management systems were added to the product portfolio. Technological independence was strengthened by the establishment of an own department for electronic hardware and software. Advanced technologies like fly-by-wire flight controls have been developed during this period. Major program milestones included the first contracts with Boeing for the 767 and E-3A as well as the selection for the German anti-tank helicopter PAH-1.

1980 - 1990

Among leading system providers

By the beginning of the 1980s, Liebherr-Aero-Technik had achieved some important goals: it had entered numerous international cooperations and had brought its own developed products onto the market. For the first time most of the turnover was generated through participation in civil programs.

Liebherr was selected to provide the flight control and air-conditioning system for the Airbus A320, which sold exceptionally well. As the production rate of the A320 was increased, the pace of production in Lindenberg had to be increased significantly as well. This was achieved by optimizing the efficiency of the industrial set-up and with high investments in modern machining centers.

Liebherr-Aero-Technik expanded its customer base both in the West, i.e. in the USA and Latin America, as well as in the East in countries such as Indonesia, Israel, China and Singapore.

At the end of the decade, the decision was taken to build-up own landing gear development capabilities.

1990 - 2000

Expansion

The 1990s were characterized by growth but began with an economic slump. Due to the Gulf War in 1991, air traffic and thus also the demand for aircraft declined. Liebherr-Aero-Technik overcame the crisis by reducing overtime and adjusting capacity.

The planned strategy of global growth was nevertheless pursued. Besides the organic growth, major acquisitions were adding capabilities, like ABG- SEMCA in Toulouse (France) – now called Liebherr-Aerospace Toulouse SAS - for air management, Feinmechanische Werke Mainz (Germany) for hydraulic actuation and the Friedrichshafen plant of ZF (Germany) for excellence in gear cutting.

In 1996, Liebherr-Aero-Technik GmbH changed its name to "Liebherr-Aerospace Lindenberg GmbH".

Liebherr-Aerospace also expanded its customer service: Service facilities were established in the USA, Singapore and Shanghai (China).

In 1997, Liebherr decided to step into the railway market by acquiring Alex. Friedmann GmbH (Austria), which had manufactured air-conditioning systems for rail vehicles among other things. In Korneuburg, near Vienna, Liebherr established its transportation technology branch and changed the company's name to Liebherr-Transportation Systems GmbH & Co KG. Know-how was supplied by Liebherr-Aerospace Lindenberg for the product area of hydraulic actuation systems and by Liebherr-Aerospace Toulouse for the air cycle air-conditioning technology.

In 1998, Liebherr-Aerospace G.I.E., based in Toulouse (France), was founded. The company's task: to coordinate all Liebherr activities in the field of aerospace and transportation technology.

.jpg)

2000 - 2010

Becoming a global player

In 2002, the divisional control company Liebherr-Aerospace G.I.E. in Toulouse (France) was restructured and renamed Liebherr-Aerospace & Transportation SAS.

A new production facility was opened in Brazil, and service stations were set up or expanded close to customers all over the world.

Many first flights and entries-into-service of aircraft programs within a few years demanded top performance from the employees and they delivered, thus contributing to Liebherr's success not only as an Original Equipment Manufacturer but also as an important player in the after-market.

The cooperation with the Brazilian aircraft manufacturer Embraer that started already in the 1990s, was further intensified, especially for landing gears. The joint venture ELEB was founded in 1999 to support Embraer’s needs for the ERJ 135/145 and later the E-Jet E1 regional aircraft programs.

In 2005, Liebherr took over business activities from Bombardier Transportation in Mannheim and founded the company Liebherr-Transportation Systems Mannheim GmbH, which offers a complete range of engineering and project management services along with customer support for the railway products.

The series production of HVAC systems for the railway market started 2009 at the new location Liebherr-Transportation System Marica EOOD (Bulgaria).

2010 - 2020

Continuous growth and major technical milestones

The long-term success story of Liebherr-Aerospace & Transportation SAS continued during the booming 2010s worldwide. With rapidly increasing aircraft fleets, Liebherr had to expand its production facilities as well as its customer services stations: A new surface treatment area, for example, as well as a new logistics center and a new manufacturing building were inaugurated in Toulouse (France) and Campsas (France), and a customer service logistics center was opened in Dubai (UAE). In Saline, Michigan (USA), Liebherr built a new customer service center to expand its heat transfer equipment repair capabilities.

In 2015, Boeing Commercial Airplanes selected Liebherr-Aerospace to supply the fold sub-system for the folding wing tip system of the Boeing 777X – a major milestone for both companies. Further contracts followed for the 777 and 787 platforms.

In the same year, Liebherr and Rolls-Royce agreed to establish a 50:50 joint venture called Aerospace Transmission Technologies GmbH, based in Friedrichshafen (Germany) to develop manufacturing capability and capacity for the power gearbox for Rolls- Royce’s new UltraFan® engine.

In 2017, Liebherr-Aerospace opened a new regional office in Bangalore that underlines the company’s long-term strategy to increase its presence and to enlarge its footprint in India.

Two years later, Liebherr founded a new company in Asia. Liebherr-Transportation Systems (China) Co., Ltd. is based in Pinghu and has the goal to grow Liebherr’s local ability to develop, test and manufacture state-of-the-art railway equipment in China.

The decade was also characterized by the introduction of advanced technologies, proving the companies pioneering mindset:

In the railway sector, Liebherr delivered an air cycle air-conditioning system to the French Public Railways Operator SNCF. This demonstrator was tested within the frame of SNCF’s “Eco-Clim” (“Green HVAC”) research program aimed at defining tomorrow’s train air-conditioning systems. The air-conditioning system uses only ambient, normal air and no refrigerant as a coolant.

Reduced greenhouse gas emissions as well as fuel burn reduction can be also achieved with Liebherr’s Electrical Environmental Control System (eECS) that completed successfully its first flight on board the Airbus A320 Flight Lab in 2016.

The year 2017 saw a world premier: On March 30, Airbus successfully flew Liebherr-Aerospace’s 3D printed spoiler actuator valve block on a flight test A380. It is the first 3D printed primary flight control hydraulic component flown on an Airbus aircraft. Already in 2019 Liebherr started serial production of 3D printed components for Airbus, i.e. nose landing gear brackets for the Airbus A350.

1960 - 1970

Entry into the aviation industry - maintenance and license production

Hans Liebherr, who founded the Liebherr family business in 1949 and was already well known as a manufacturer of construction machinery and refrigerators, entered the aviation industry in the year 1960.

By 1965, Liebherr-Aero-Technik GmbH had established itself as a successful license company for the manufacturing of landing gears and hydraulic equipment, but it did not develop or manufacture its own products. Hans Liebherr took the decision to develop the company from a licensee to an original equipment manufacturer (OEM) providing complete systems to the aviation industry.

In November 1969, an important milestone was reached: Liebherr-Aero-Technik and the British aviation company H.M. Hobson won the contract for the development and manufacture of the slat and flap actuation system for the new European aircraft program Airbus A300.

1970 - 1980

Technological expansion and international orientation

As an OEM and through cooperation with partner companies, Liebherr-Aero-Technik was able to develop its activities into new products and markets. Flight control systems and air management systems were added to the product portfolio. Technological independence was strengthened by the establishment of an own department for electronic hardware and software. Advanced technologies like fly-by-wire flight controls have been developed during this period. Major program milestones included the first contracts with Boeing for the 767 and E-3A as well as the selection for the German anti-tank helicopter PAH-1.

1980 - 1990

Among leading system providers

By the beginning of the 1980s, Liebherr-Aero-Technik had achieved some important goals: it had entered numerous international cooperations and had brought its own developed products onto the market. For the first time most of the turnover was generated through participation in civil programs.

Liebherr was selected to provide the flight control and air-conditioning system for the Airbus A320, which sold exceptionally well. As the production rate of the A320 was increased, the pace of production in Lindenberg had to be increased significantly as well. This was achieved by optimizing the efficiency of the industrial set-up and with high investments in modern machining centers.

Liebherr-Aero-Technik expanded its customer base both in the West, i.e. in the USA and Latin America, as well as in the East in countries such as Indonesia, Israel, China and Singapore.

At the end of the decade, the decision was taken to build-up own landing gear development capabilities.

1990 - 2000

Expansion

The 1990s were characterized by growth but began with an economic slump. Due to the Gulf War in 1991, air traffic and thus also the demand for aircraft declined. Liebherr-Aero-Technik overcame the crisis by reducing overtime and adjusting capacity.

The planned strategy of global growth was nevertheless pursued. Besides the organic growth, major acquisitions were adding capabilities, like ABG- SEMCA in Toulouse (France) – now called Liebherr-Aerospace Toulouse SAS - for air management, Feinmechanische Werke Mainz (Germany) for hydraulic actuation and the Friedrichshafen plant of ZF (Germany) for excellence in gear cutting.

In 1996, Liebherr-Aero-Technik GmbH changed its name to "Liebherr-Aerospace Lindenberg GmbH".

Liebherr-Aerospace also expanded its customer service: Service facilities were established in the USA, Singapore and Shanghai (China).

In 1997, Liebherr decided to step into the railway market by acquiring Alex. Friedmann GmbH (Austria), which had manufactured air-conditioning systems for rail vehicles among other things. In Korneuburg, near Vienna, Liebherr established its transportation technology branch and changed the company's name to Liebherr-Transportation Systems GmbH & Co KG. Know-how was supplied by Liebherr-Aerospace Lindenberg for the product area of hydraulic actuation systems and by Liebherr-Aerospace Toulouse for the air cycle air-conditioning technology.

In 1998, Liebherr-Aerospace G.I.E., based in Toulouse (France), was founded. The company's task: to coordinate all Liebherr activities in the field of aerospace and transportation technology.

.jpg)

2000 - 2010

Becoming a global player

In 2002, the divisional control company Liebherr-Aerospace G.I.E. in Toulouse (France) was restructured and renamed Liebherr-Aerospace & Transportation SAS.

A new production facility was opened in Brazil, and service stations were set up or expanded close to customers all over the world.

Many first flights and entries-into-service of aircraft programs within a few years demanded top performance from the employees and they delivered, thus contributing to Liebherr's success not only as an Original Equipment Manufacturer but also as an important player in the after-market.

The cooperation with the Brazilian aircraft manufacturer Embraer that started already in the 1990s, was further intensified, especially for landing gears. The joint venture ELEB was founded in 1999 to support Embraer’s needs for the ERJ 135/145 and later the E-Jet E1 regional aircraft programs.

In 2005, Liebherr took over business activities from Bombardier Transportation in Mannheim and founded the company Liebherr-Transportation Systems Mannheim GmbH, which offers a complete range of engineering and project management services along with customer support for the railway products.

The series production of HVAC systems for the railway market started 2009 at the new location Liebherr-Transportation System Marica EOOD (Bulgaria).

2010 - 2020

Continuous growth and major technical milestones

The long-term success story of Liebherr-Aerospace & Transportation SAS continued during the booming 2010s worldwide. With rapidly increasing aircraft fleets, Liebherr had to expand its production facilities as well as its customer services stations: A new surface treatment area, for example, as well as a new logistics center and a new manufacturing building were inaugurated in Toulouse (France) and Campsas (France), and a customer service logistics center was opened in Dubai (UAE). In Saline, Michigan (USA), Liebherr built a new customer service center to expand its heat transfer equipment repair capabilities.

In 2015, Boeing Commercial Airplanes selected Liebherr-Aerospace to supply the fold sub-system for the folding wing tip system of the Boeing 777X – a major milestone for both companies. Further contracts followed for the 777 and 787 platforms.

In the same year, Liebherr and Rolls-Royce agreed to establish a 50:50 joint venture called Aerospace Transmission Technologies GmbH, based in Friedrichshafen (Germany) to develop manufacturing capability and capacity for the power gearbox for Rolls- Royce’s new UltraFan® engine.

In 2017, Liebherr-Aerospace opened a new regional office in Bangalore that underlines the company’s long-term strategy to increase its presence and to enlarge its footprint in India.

Two years later, Liebherr founded a new company in Asia. Liebherr-Transportation Systems (China) Co., Ltd. is based in Pinghu and has the goal to grow Liebherr’s local ability to develop, test and manufacture state-of-the-art railway equipment in China.

The decade was also characterized by the introduction of advanced technologies, proving the companies pioneering mindset:

In the railway sector, Liebherr delivered an air cycle air-conditioning system to the French Public Railways Operator SNCF. This demonstrator was tested within the frame of SNCF’s “Eco-Clim” (“Green HVAC”) research program aimed at defining tomorrow’s train air-conditioning systems. The air-conditioning system uses only ambient, normal air and no refrigerant as a coolant.

Reduced greenhouse gas emissions as well as fuel burn reduction can be also achieved with Liebherr’s Electrical Environmental Control System (eECS) that completed successfully its first flight on board the Airbus A320 Flight Lab in 2016.

The year 2017 saw a world premier: On March 30, Airbus successfully flew Liebherr-Aerospace’s 3D printed spoiler actuator valve block on a flight test A380. It is the first 3D printed primary flight control hydraulic component flown on an Airbus aircraft. Already in 2019 Liebherr started serial production of 3D printed components for Airbus, i.e. nose landing gear brackets for the Airbus A350.