Components

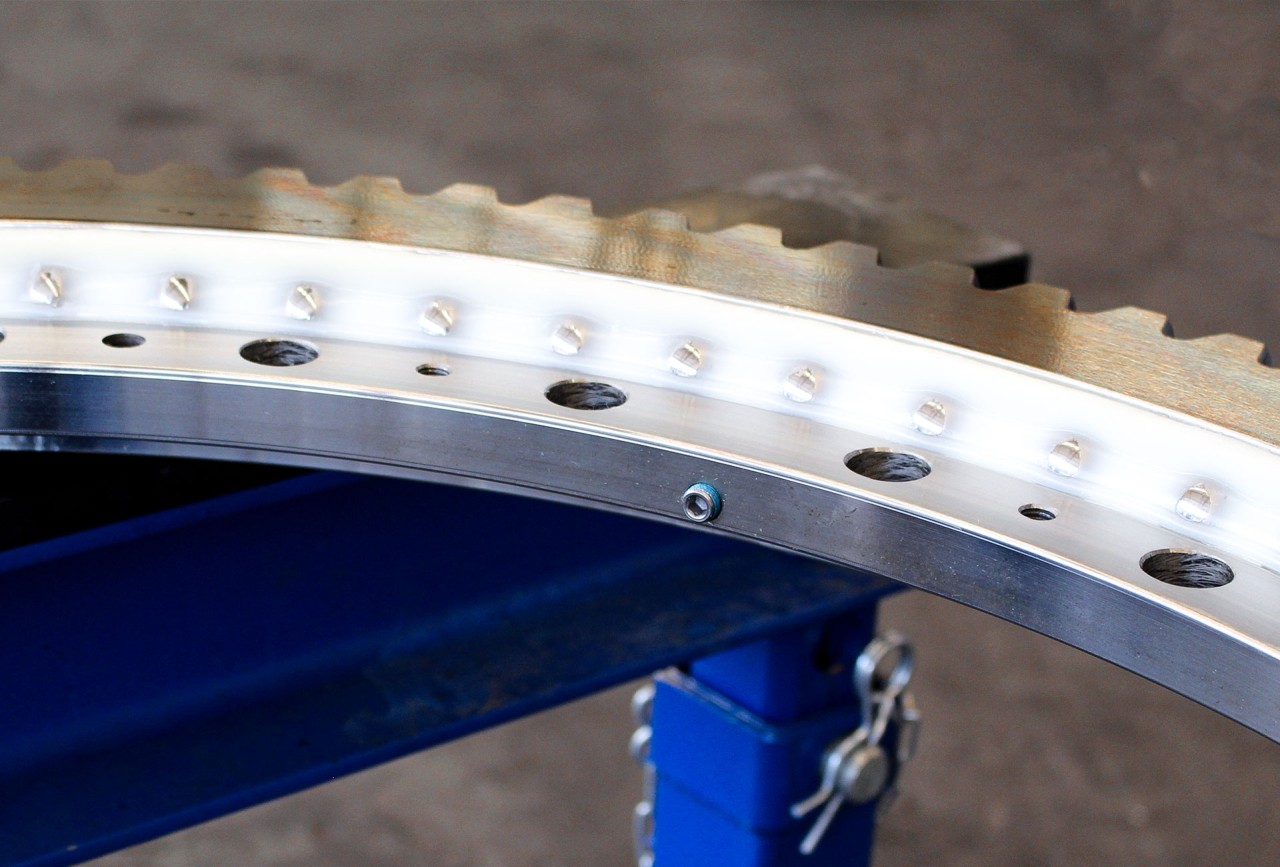

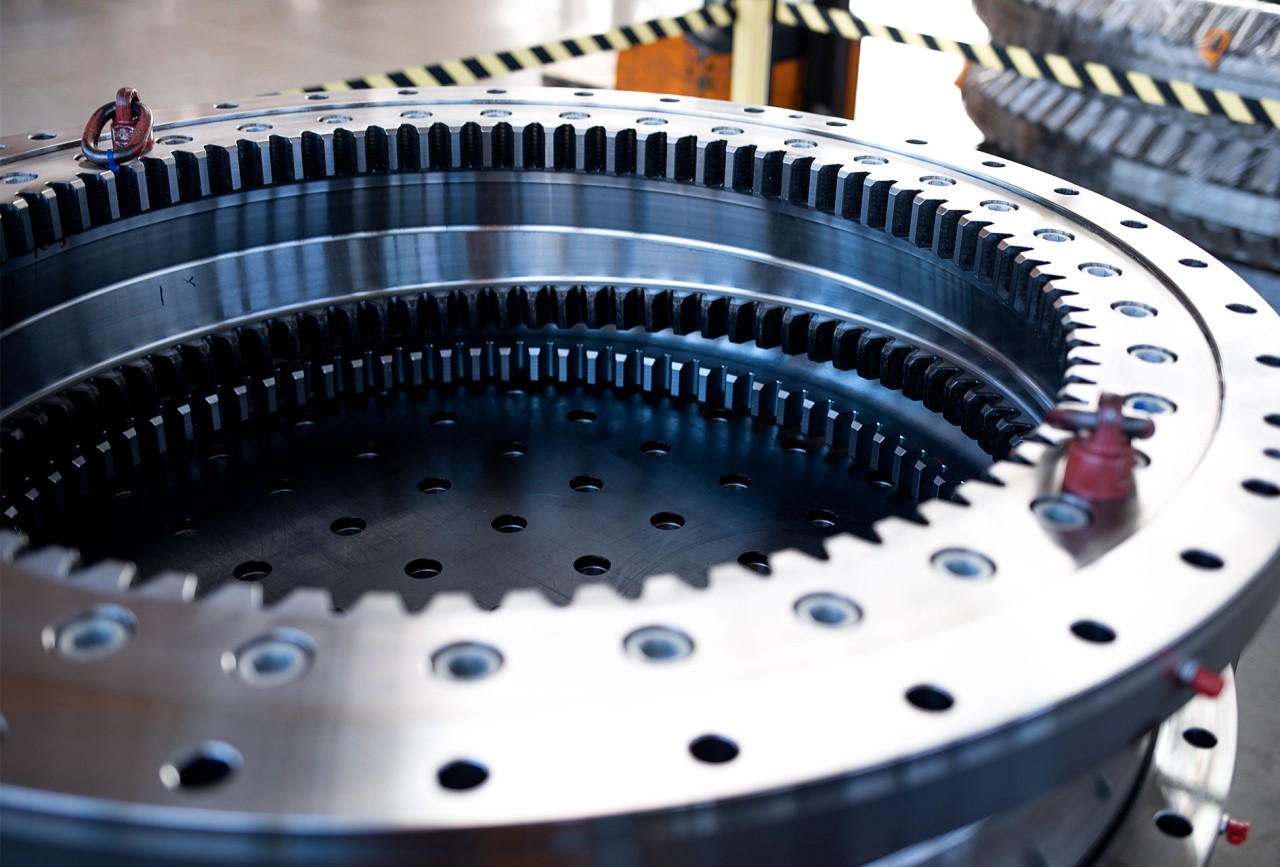

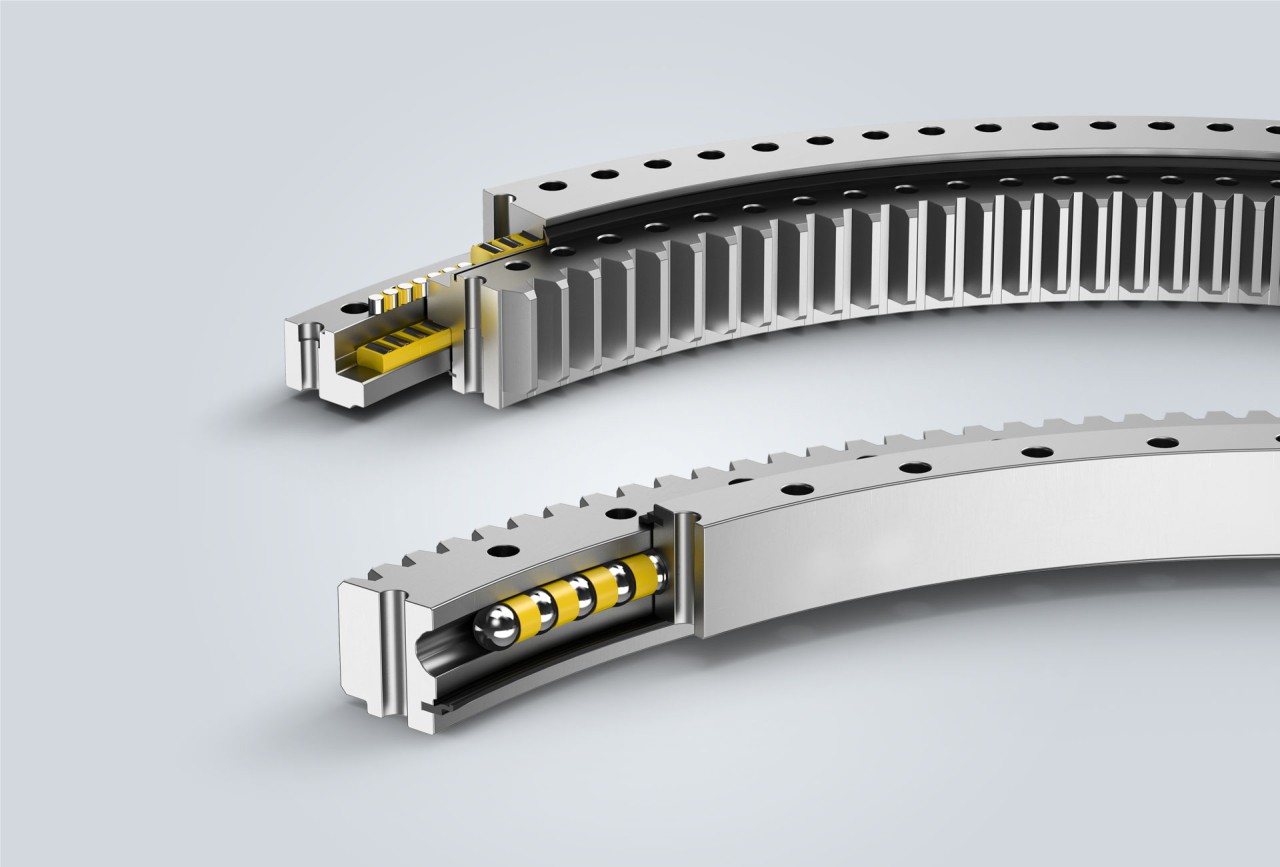

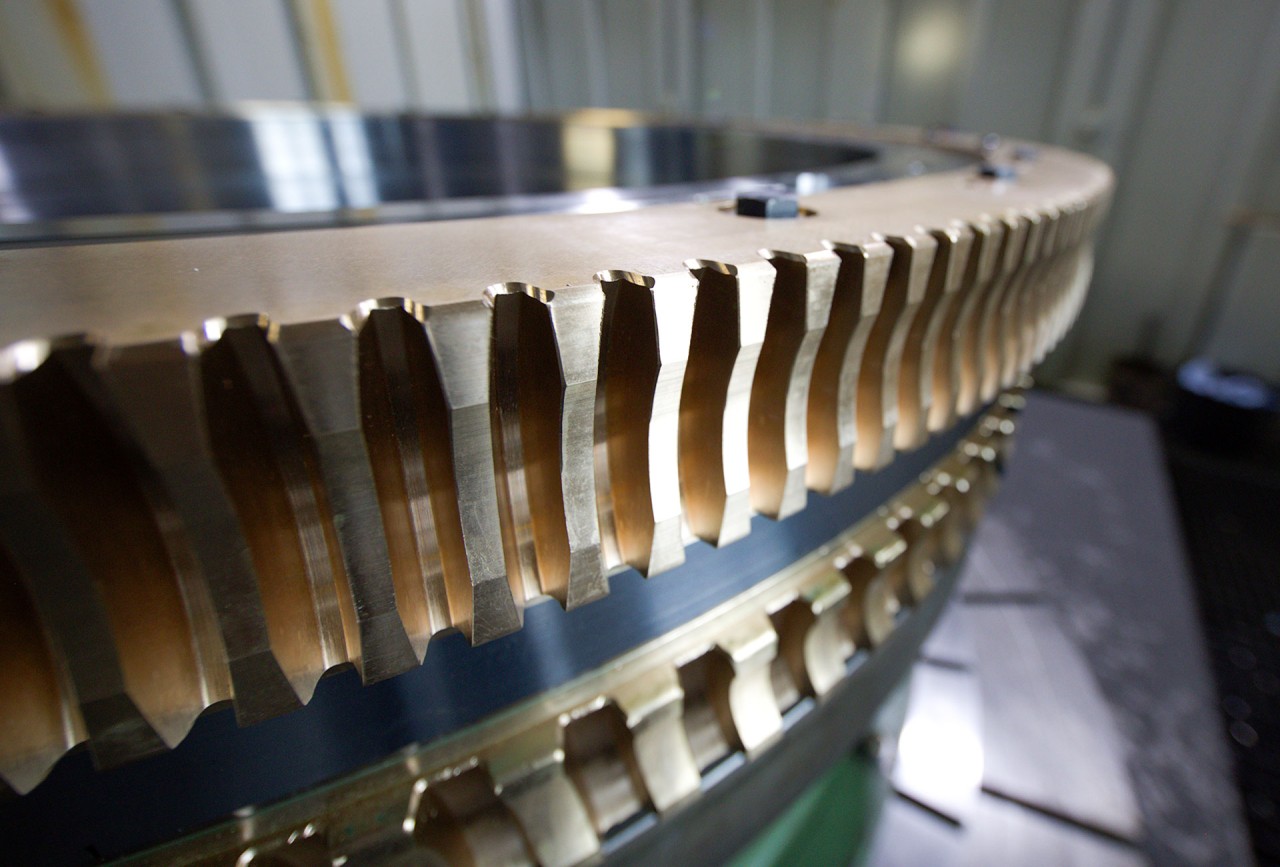

ComponentsOur unique solutions – your movement: Slewing bearings and slew drives for precision applications and special machines

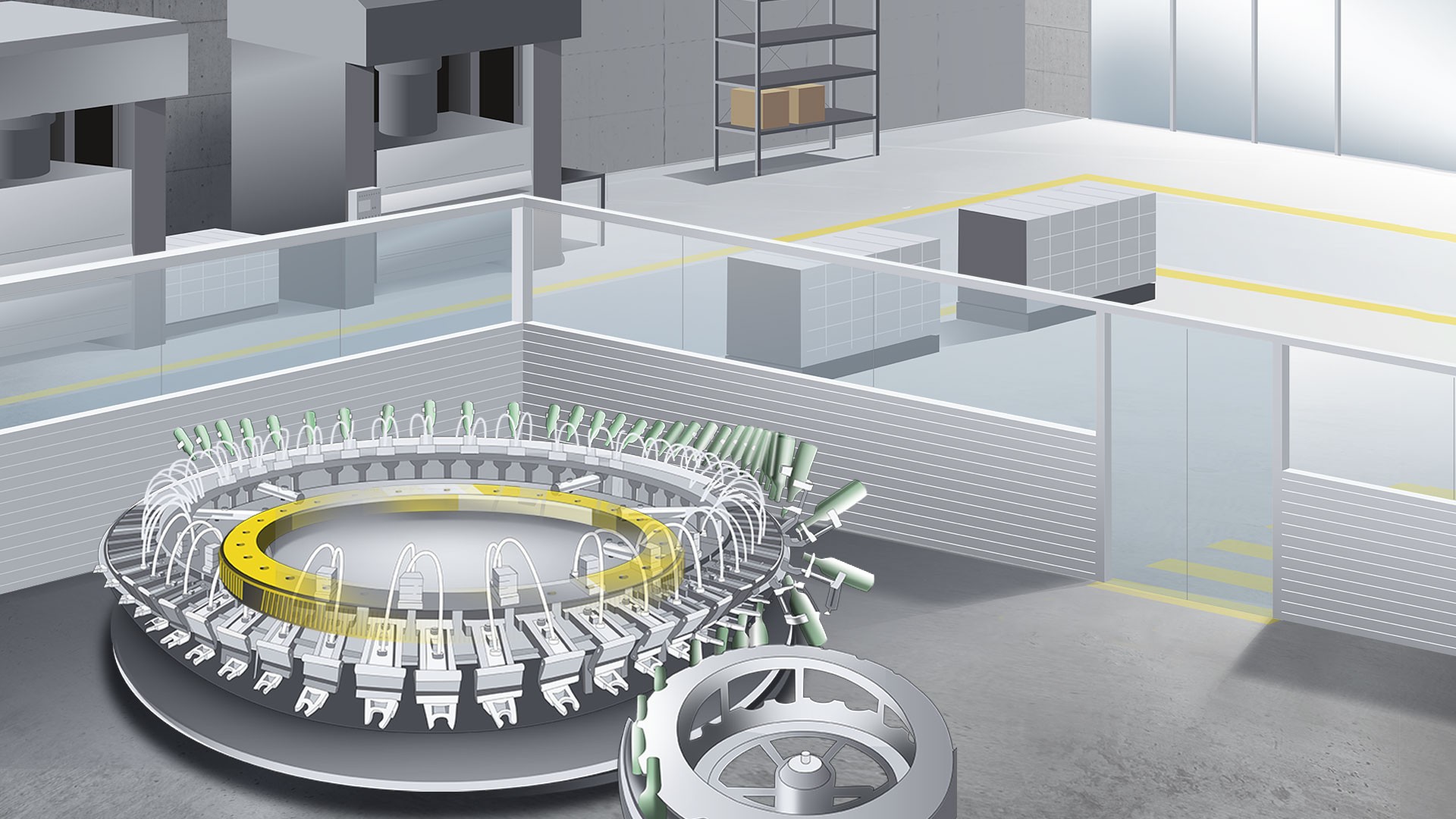

Looking for slewing bearings in your precision applications or special machines? Look no further than our selection of top-quality slewing bearings and slew drives. Our products are designed to deliver superior performance, reliability, and durability, even in the most demanding environments, such as ladle turrets or amusement rides. With a range of sizes and configurations to choose from, we have the perfect solution for your specific needs. Contact us today to learn more about how our slewing bearings and slew drives can help you achieve precision and efficiency in your applications.

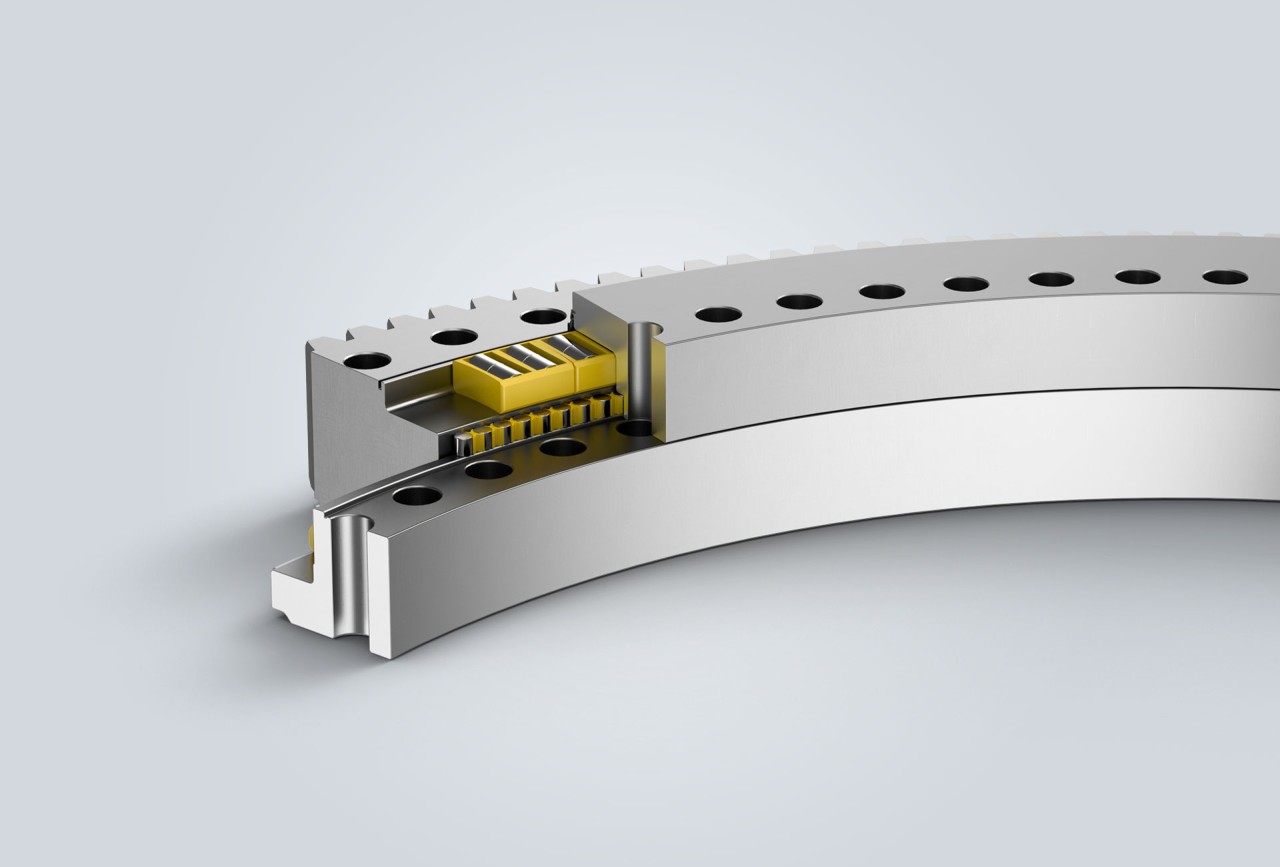

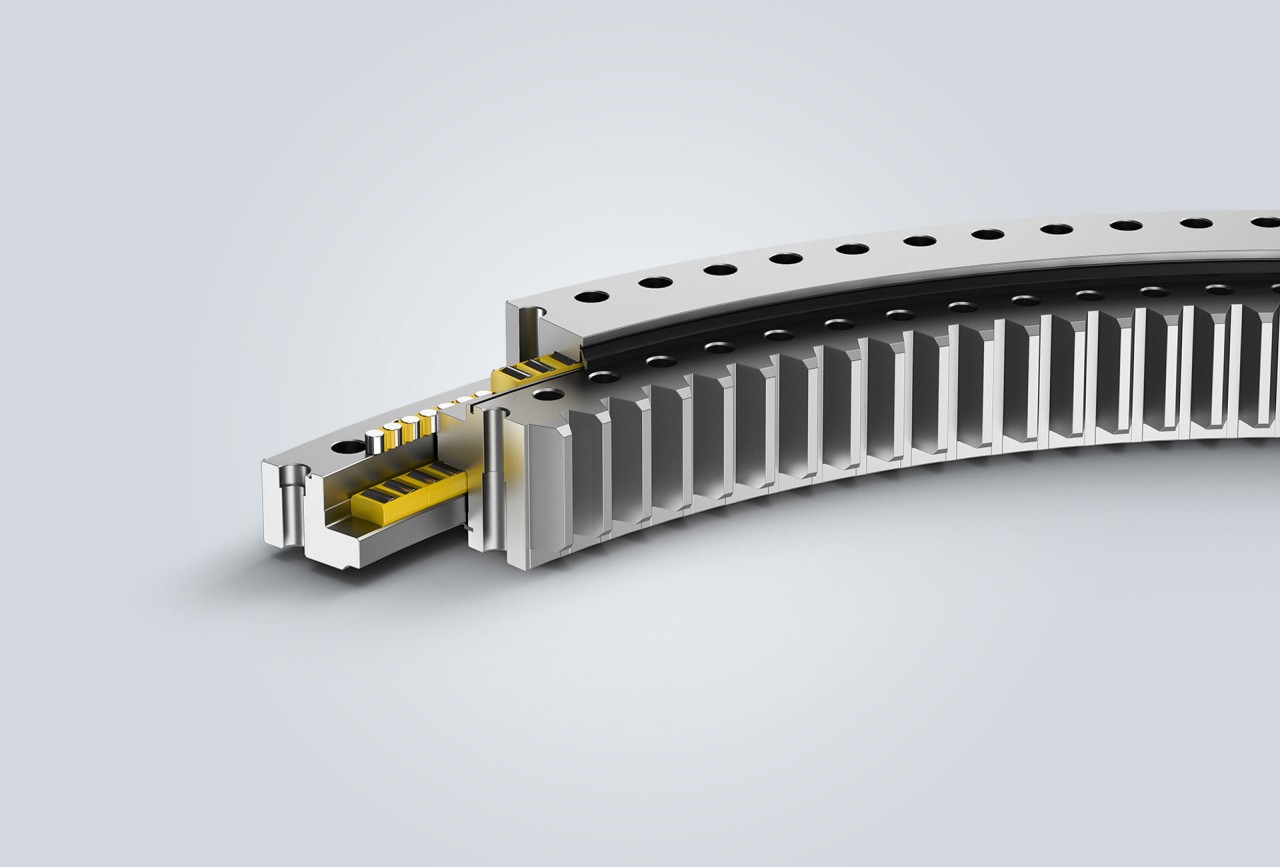

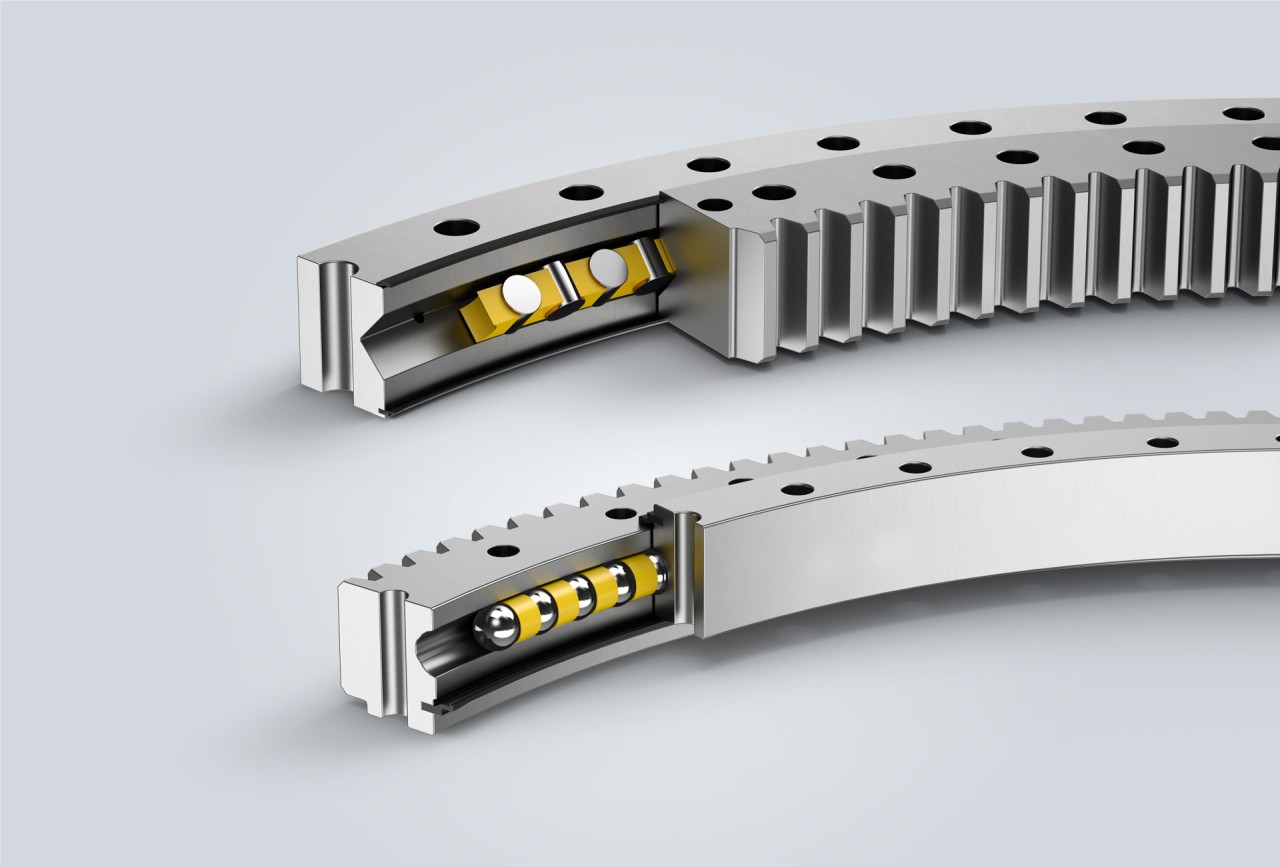

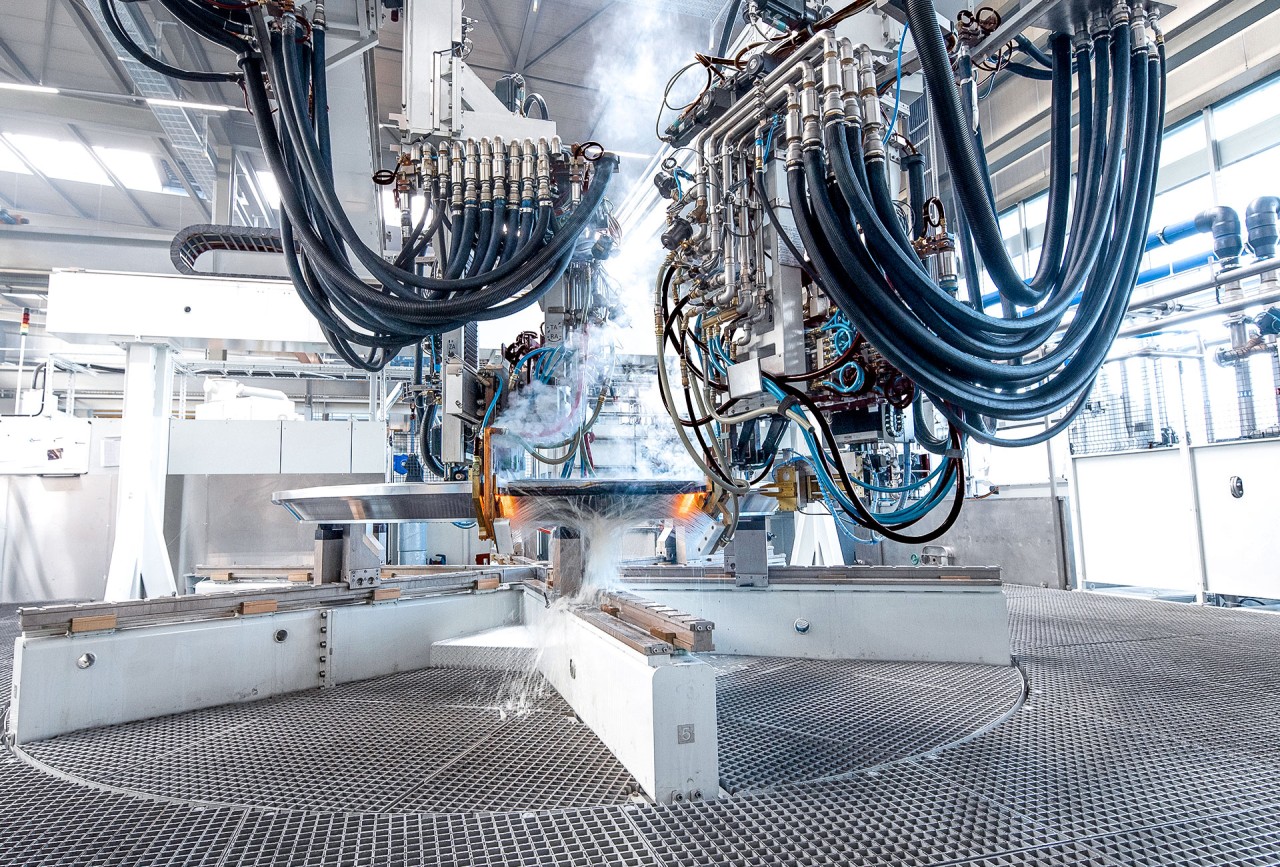

Ladle turrets: Slewing bearings and their features

Pelletizing disks: Slewing bearings and their features

Bottle filling machines: Slewing bearings and their features

Amusement rides: Slewing bearings, slew drives and their features

Turntable ladders for fire trucks: Slewing bearings and their features

Machine tools: Slewing bearings and their features

Get in touch

Contact our local sales team or follow us on our LinkedIn channel.