Supporting circular economy

Supporting circular economy

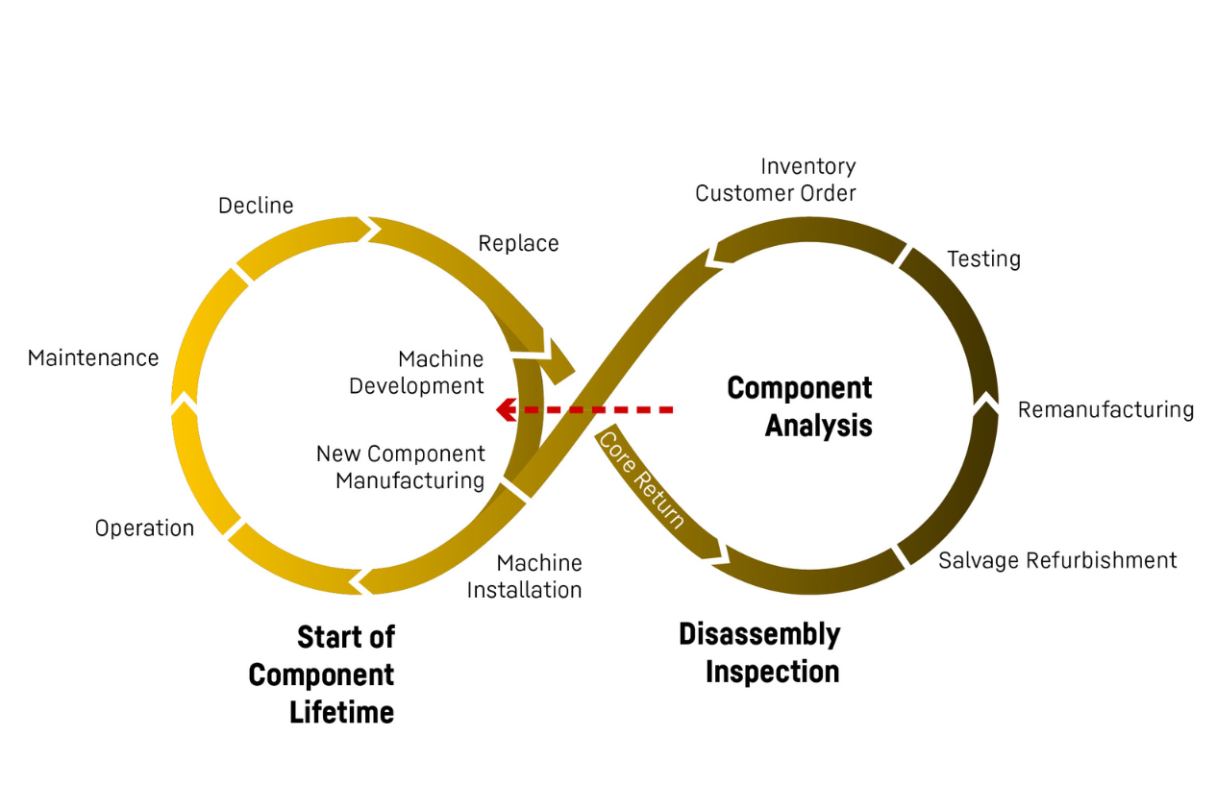

Sustainability is a vital part of the work we do at Liebherr Mining and as such is deeply embedded within Liebherr Reman’s operations. Our remanufacturing processes are designed to conserve resources, extend the life cycle of components and reduce the overall ownership costs of your Liebherr equipment. By keeping parts within the value chain, we not only minimise waste but also contribute to a more sustainable future.

See how Liebherr Reman contributes to the circular economy

Using cores to their fullest potential

Liebherr Reman ensures that all of the cores it receives are used to their fullest potential. During the remanufacturing process, Liebherr reuses as much material from each core as possible to minimise waste. Once these cores have been remanufactured into same-as-new Liebherr parts and components, they are reintroduced into the supply chain. This process allows Liebherr to provide customers with high-quality products while also minimising the need to use raw materials.

A second life for used products!