The RL series - compact and versatile

The particularly weight-optimized and compact design is the characteristic feature of the RL series.

On both fixed and floating offshore installations, especially in the wind power industry and in the oil and gas sector, RL cranes are mainly used for maintenance and supply work.

Equipped with Liebherr Intelligent Maintenance (LiMain), the cranes have reduced maintenance efforts and thus increased crane availability at lower costs.

The RL series - compact and versatile

The particularly weight-optimized and compact design is the characteristic feature of the RL series.

On both fixed and floating offshore installations, especially in the wind power industry and in the oil and gas sector, RL cranes are mainly used for maintenance and supply work.

Equipped with Liebherr Intelligent Maintenance (LiMain), the cranes have reduced maintenance efforts and thus increased crane availability at lower costs.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Excursion on the RL 2600

On our test stand at our Rostock plant, our expert will take you on a tour of the RL 2600. Let yourself be inspired by our most compact crane solution from Liebherr's offshore portfolio!

Various solutions depending on customer needs

| Crane type | RL 900 | RL 1500 | RL 2600 | RL 4600 |

|---|---|---|---|---|

| Max. capacity | 30 tons | 50 tons | 75 tons | 100 tons |

| Outreach | 36 metres | 42 metres | 48 metres | 55 metres |

Highlights of the RL series

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

Customers voice

"For platform operators, weight and space requirements for equipment are key cost elements. Any reduction ensures savings, which is why Liebherr's RL crane is the number one choice. It is lightweight, reliable and flexible in terms of positioning. In addition, our crane operators are delighted with the ease of maintenance and sensitive crane control."

Steve Haro, Head of Operations, Navtech Marine Services

Talk to our specialists

The RL series in a nutshell

- Design

- Cabin

- Maintenance

- Service

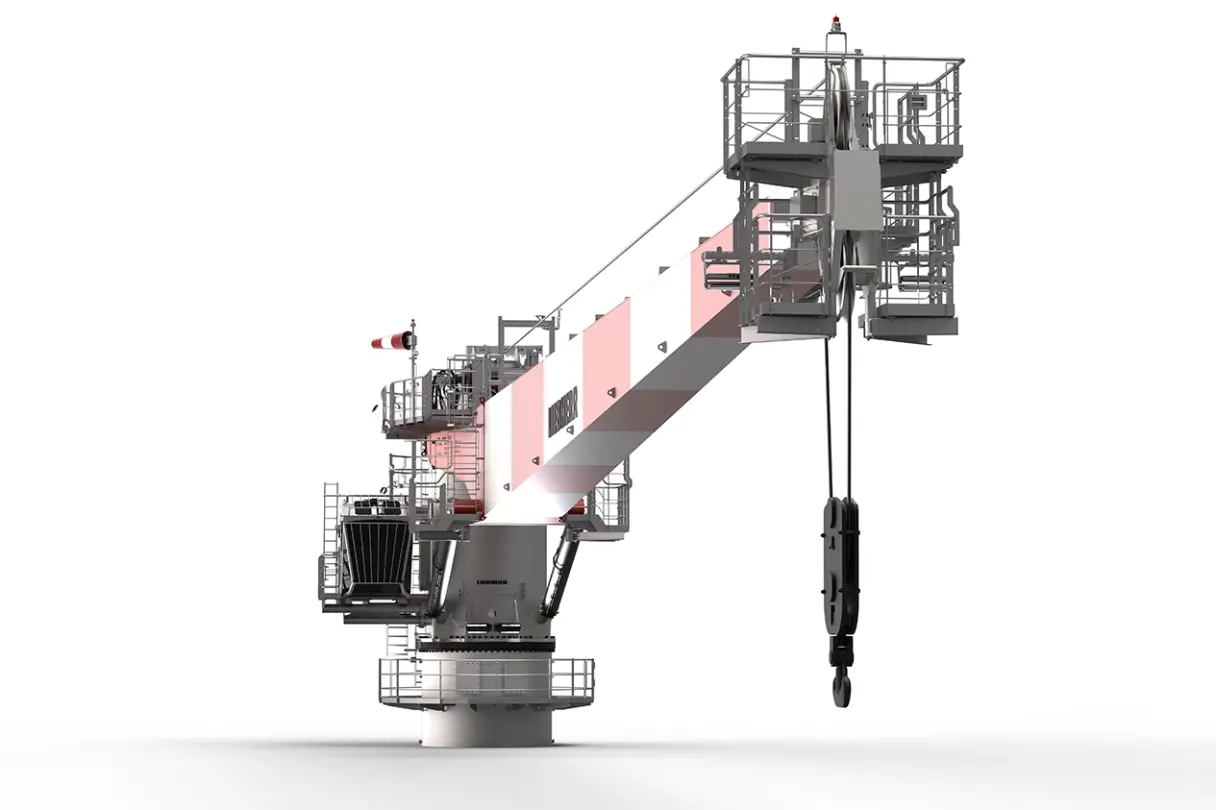

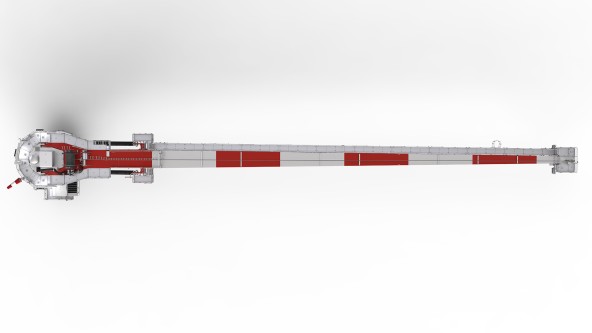

Design

Based on our customers feedback, we optimized the RL to become the most compact maintenance crane. This results in a reduced construction height and a small tail radius. The elimination of a machinery house allows the crane to operate in confined space conditions and environments. Additionally, the crane can be ex-certified (ATEX and IECEx).

Design

Based on our customers feedback, we optimized the RL to become the most compact maintenance crane. This results in a reduced construction height and a small tail radius. The elimination of a machinery house allows the crane to operate in confined space conditions and environments. Additionally, the crane can be ex-certified (ATEX and IECEx).

Available for the RL series: LiMain

LiMain is a fully digital, remote and semi-automatic maintenance system, which saves investments and resources for the platform operator.

Ram luffing crane: special features in detail

Depending on the model, lifting capacities of up to 100 tonnes are possible. The RL crane can be electrically or diesel-hydraulically powered and is available according to the required classification for maximum safety in hazardous areas.

The small tail radius as well as the low construction height make the ram luffing crane an ideal application for small and unmanned platforms or vessels.

EXpressure

A special feature of the new RL crane series is the innovative cabinet inside the slewing column. The technology behind this innovation is called "EXpressure", the world's first explosion-proof Ex d cabinet that safely releases explosion pressure. It has been developed by our partner R. Stahl AG.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).LiMain remote maintenance showcase

To avoid having to send service personnel to offshore platforms for every maintenance job, the demand for remote-controlled maintenance systems is growing rapidly. We recognised this trend early on and developed Liebherr Intelligent Maintenance (LiMain). It paves the way for an even higher crane availability at lower operational costs (OPEX) on offshore. The fully digital, semi-automatic, and remote maintenance system offers more independency of time, place and resources for platform owners, resulting in never-before-seen savings.