Extensive range of modules

To set-up production lines to solve complex tasks, Liebherr supplies not only basic components but also all of the requisite additional equipment.

Additional equipment from one source

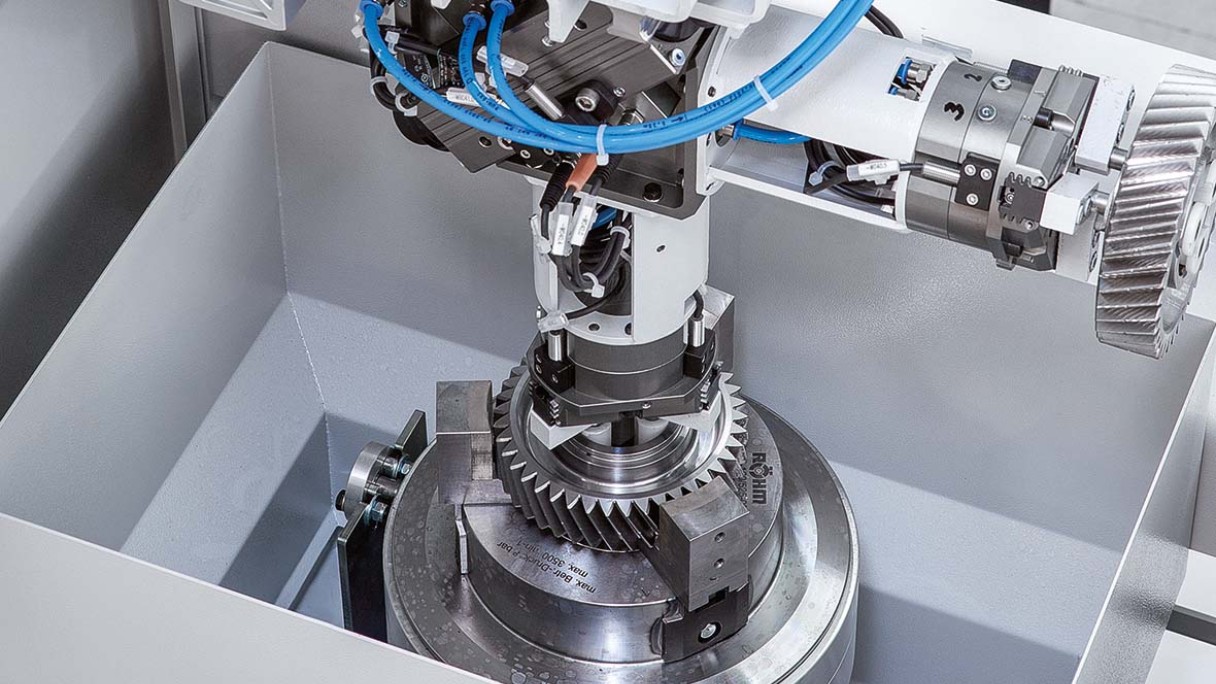

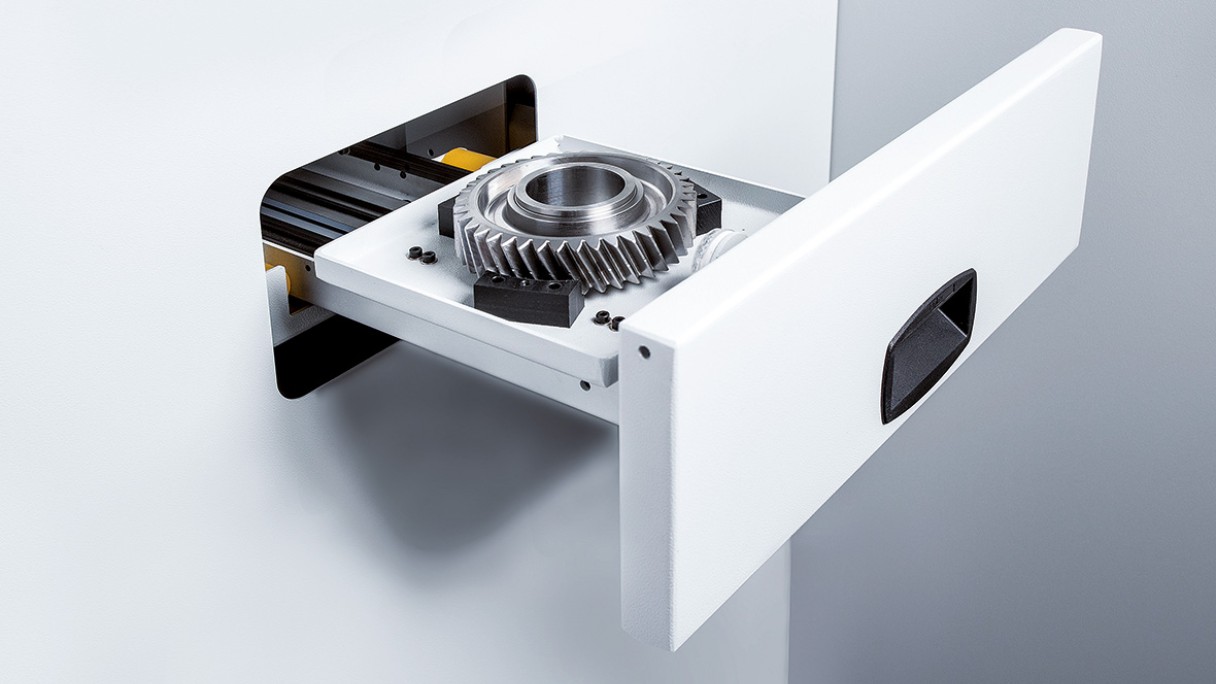

With the additional equipment, too, Liebherr draws on an extensive range of modules. Among these, for example, are lettering, recognition by means of camera systems and the discharge of measuring parts.

Labelling systems

Centrifugal station

Statistical process control (SPC)

Our product

Results 1-1 of 1