We dig it!

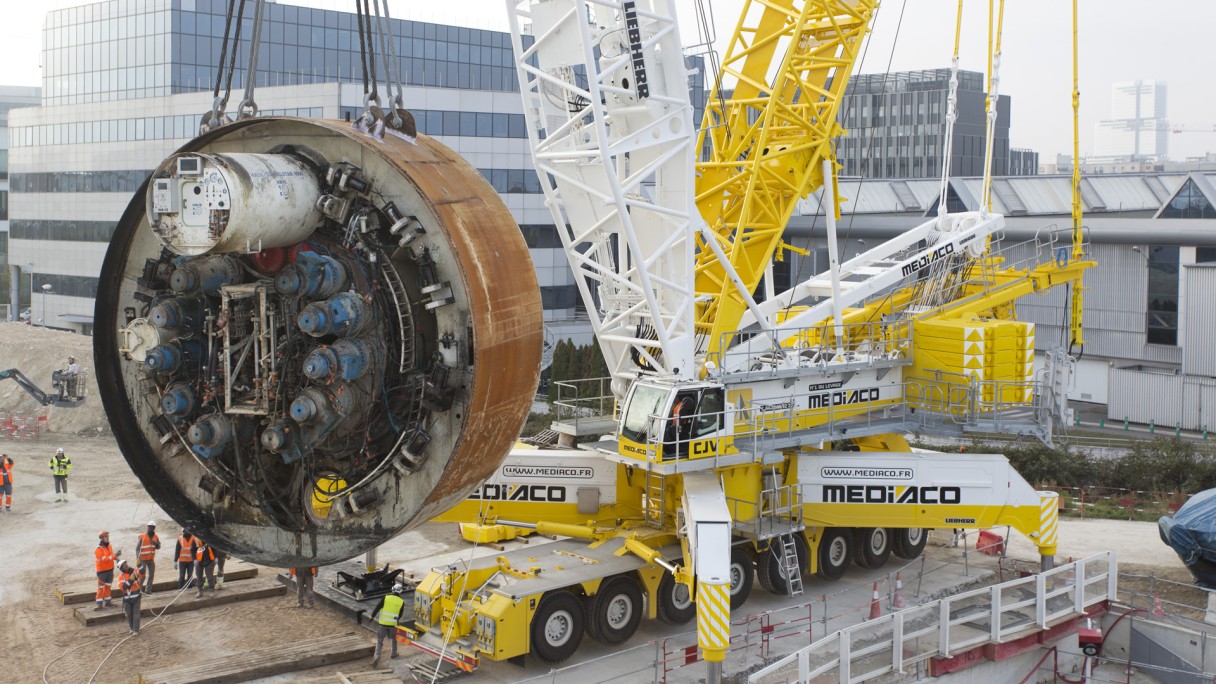

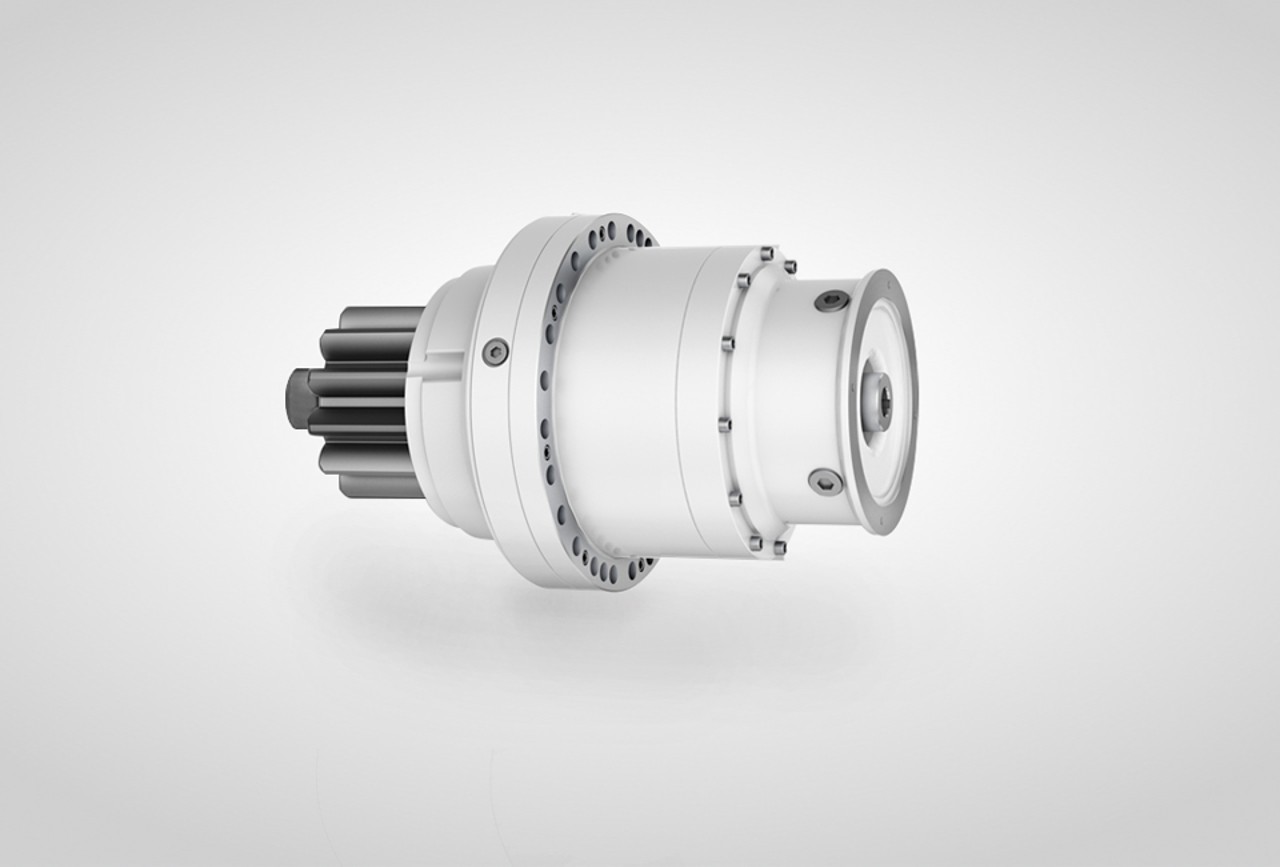

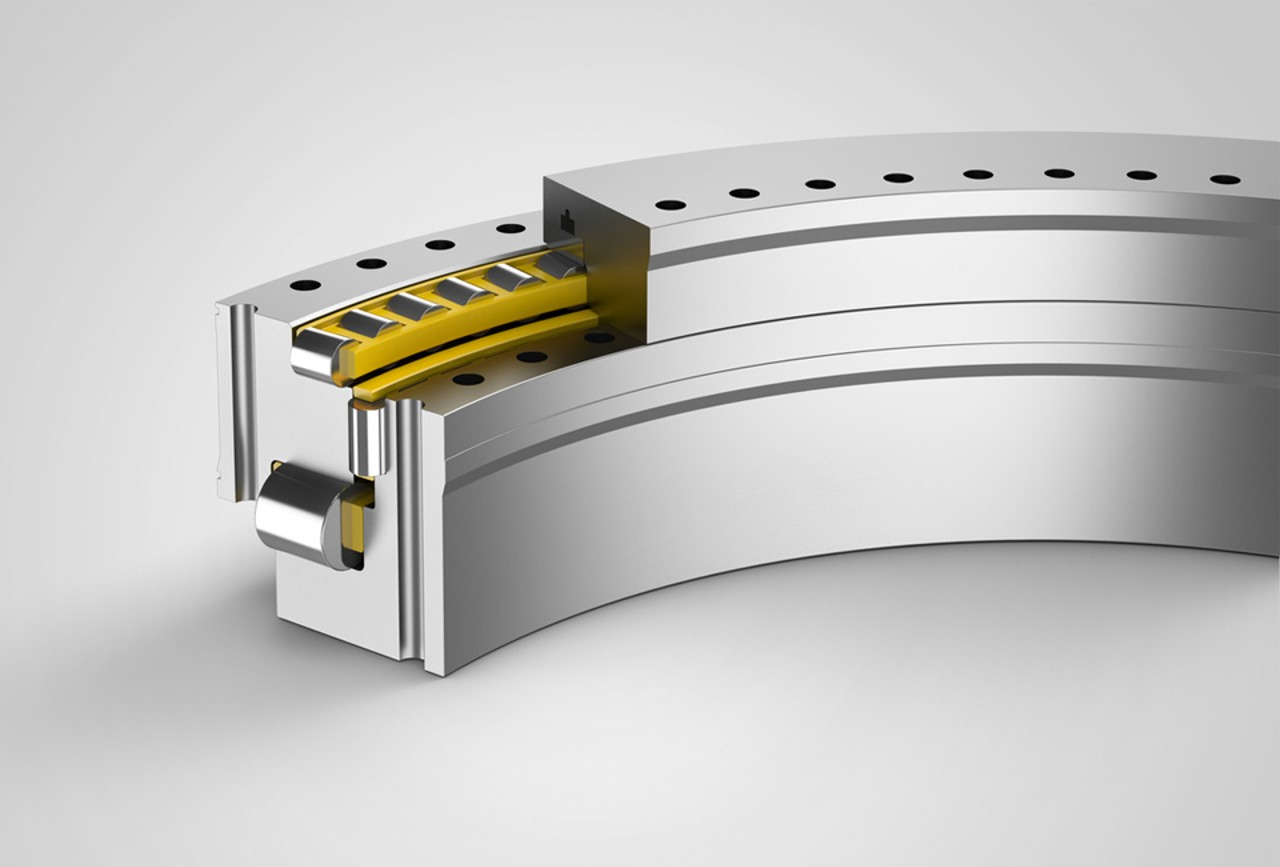

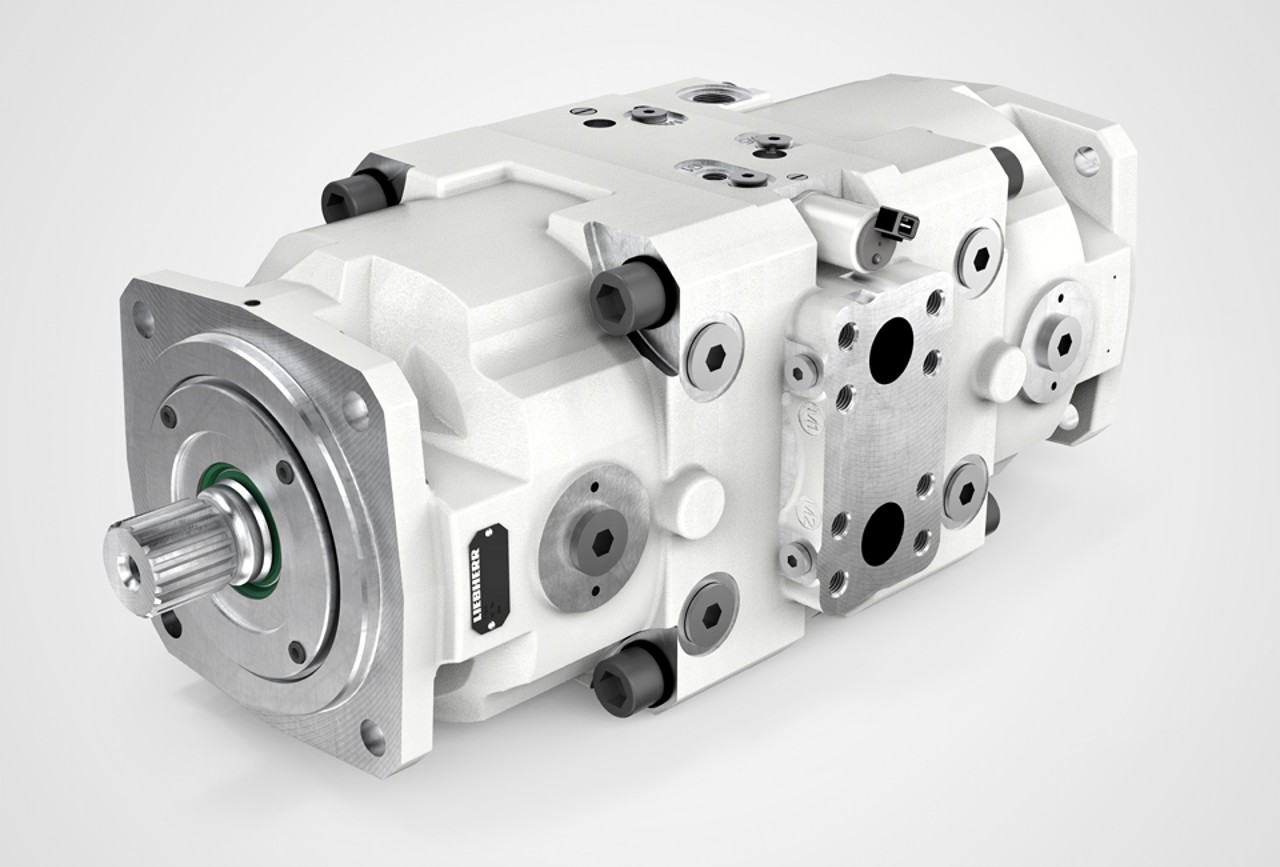

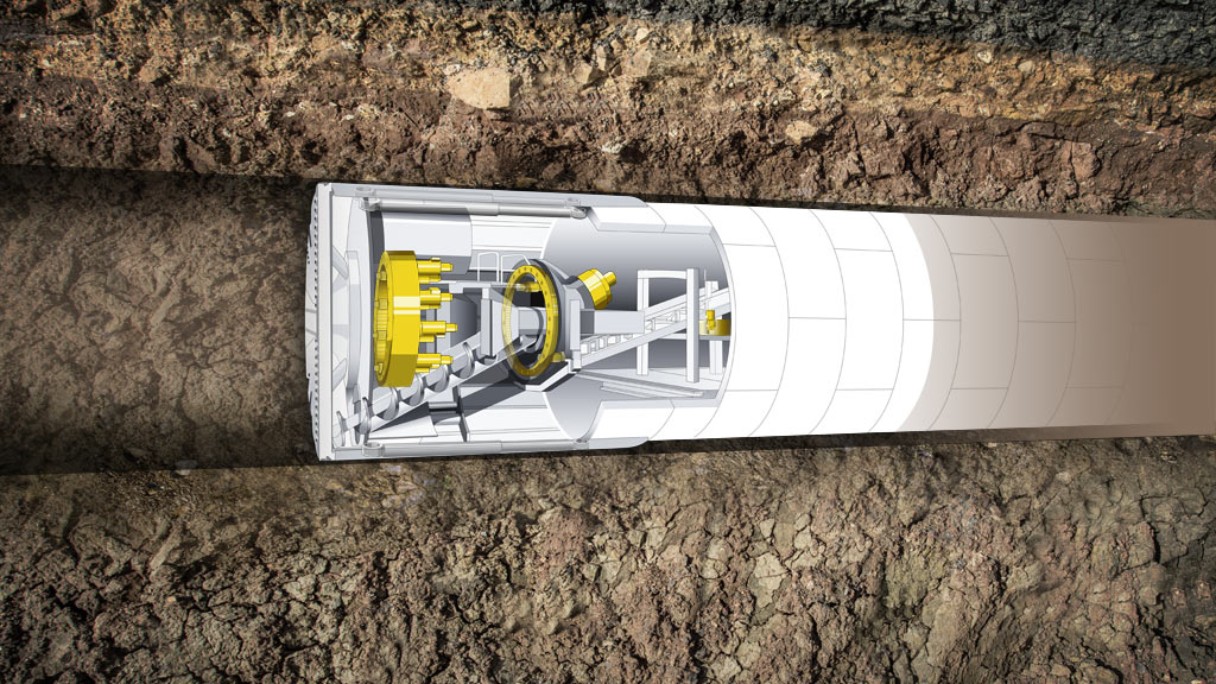

Liebherr components for tunnelling are specifically designed for toughest loads in continuous operation and have a proven track record of success in the field. You will find them in tunnel boring machines from renowned companies in numerous tunnel boring projects all around the world.

No time for downtime

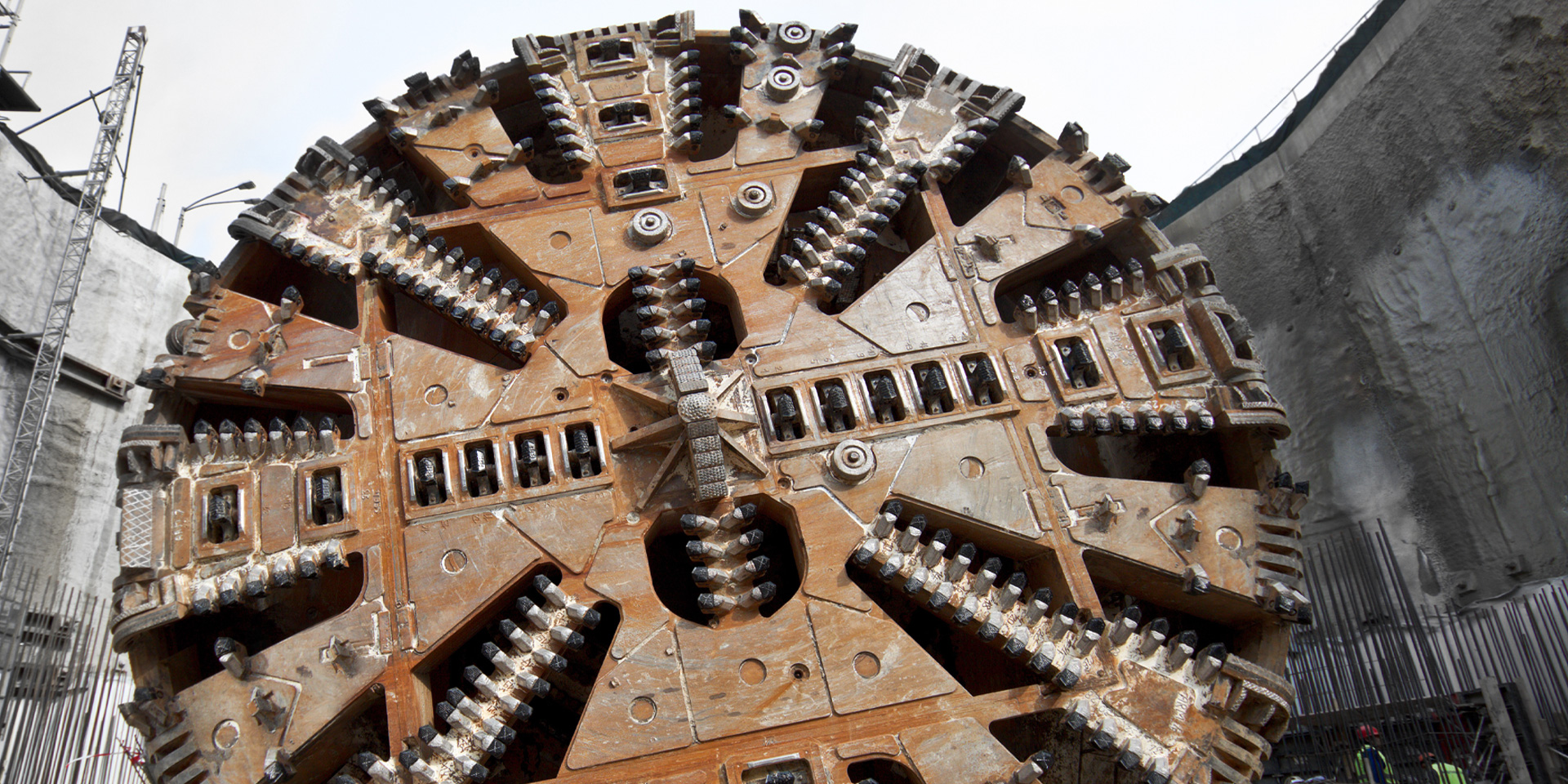

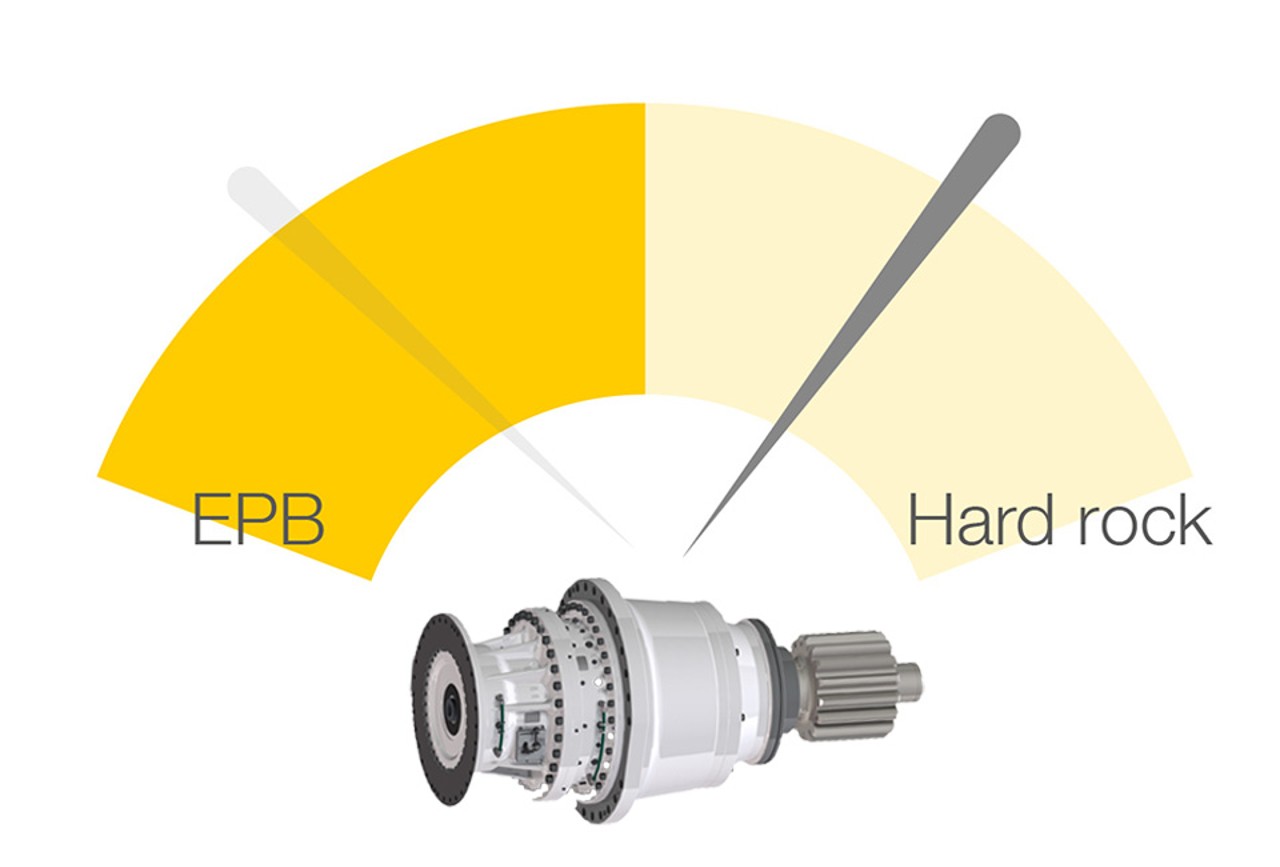

Tunnel boring equipment is facing several challenges during operation. On the one hand there are extreme soil conditions, from hard rock to erosive soil and EPB. On the other, long project scopes and narrow timeframes with short reaction times. Given these circumstances, one thing is clear: You have no time for machine-downtimes.

In order to assure a successful project completion it is therefore essential to have, above all, reliable equipment.

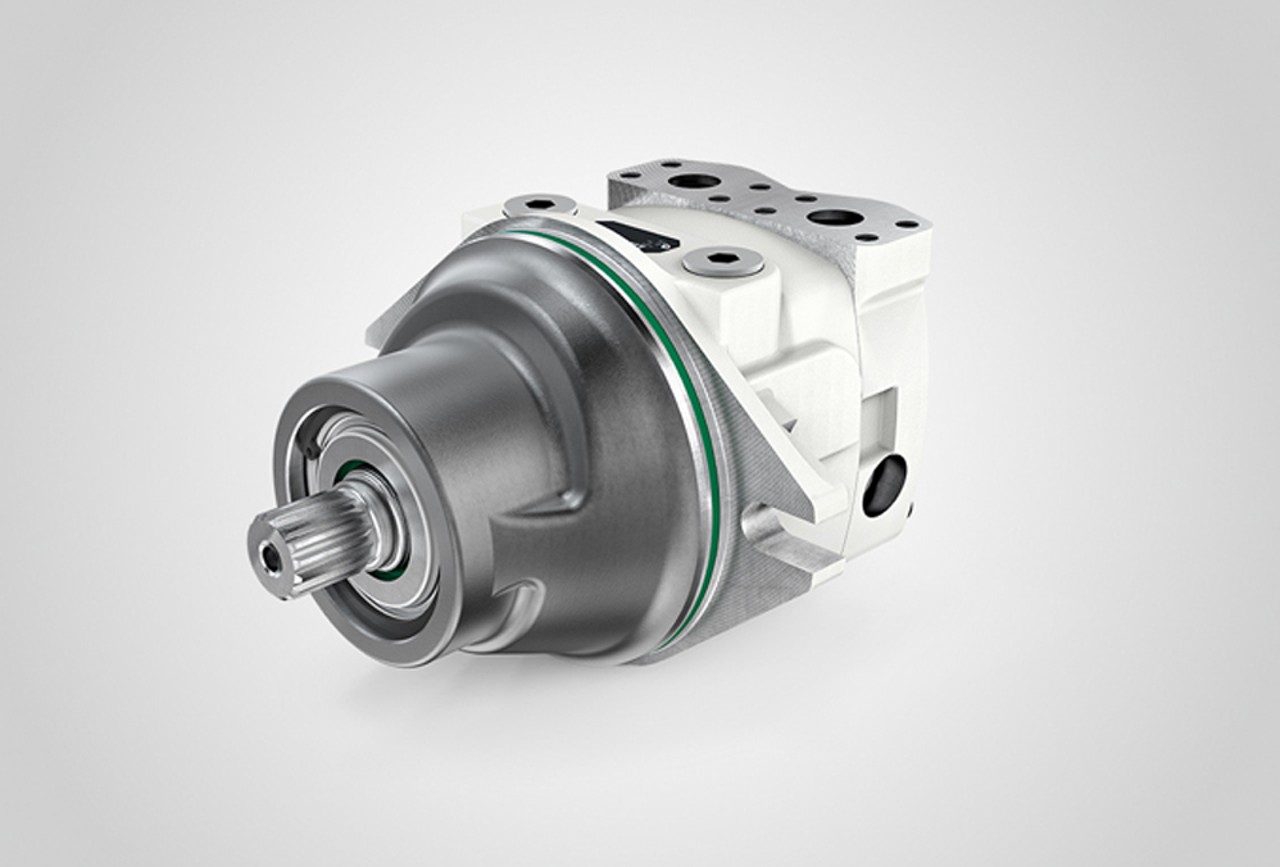

Make the breakthrough: Components for Earth Pressure Balance (EPB) tunnel boring machines

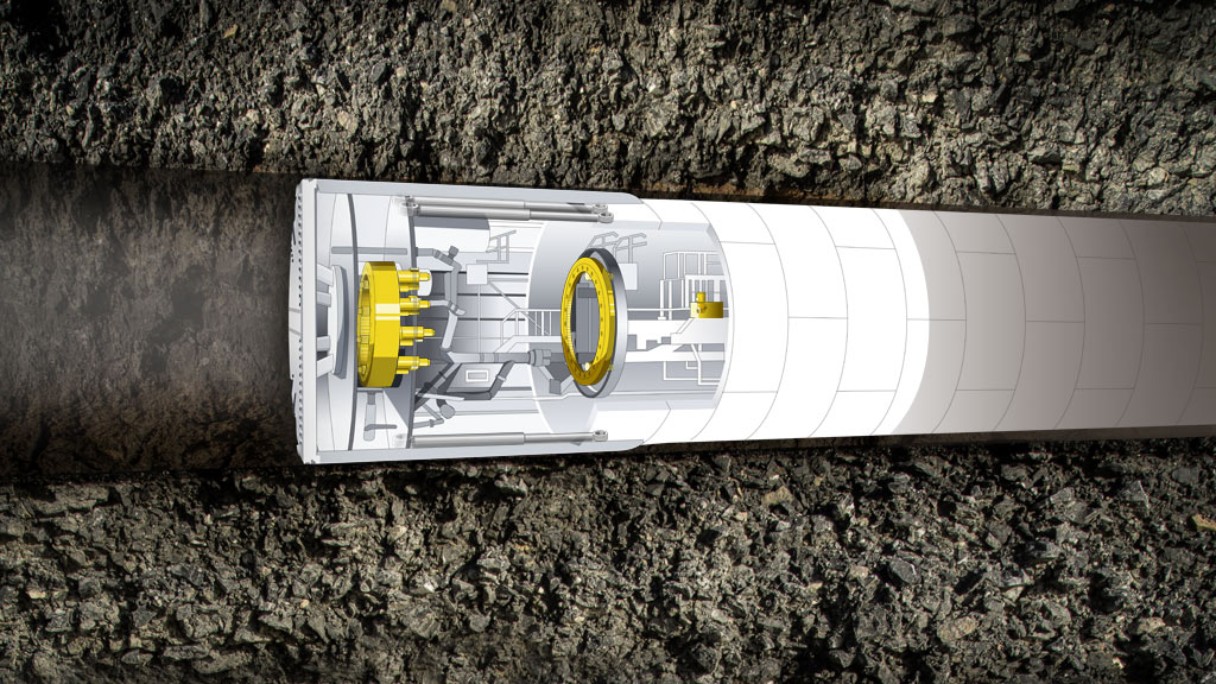

Heavy metal vs. hard rock: Components for hard rock tunnel boring machines

Whatever may come: Components for dual mode tunnel boring machines

Reference stories

Why do companies like the Robbins Company choose Liebherr components for their tunnelling projects? Request our reference story here and discover your possibilities.

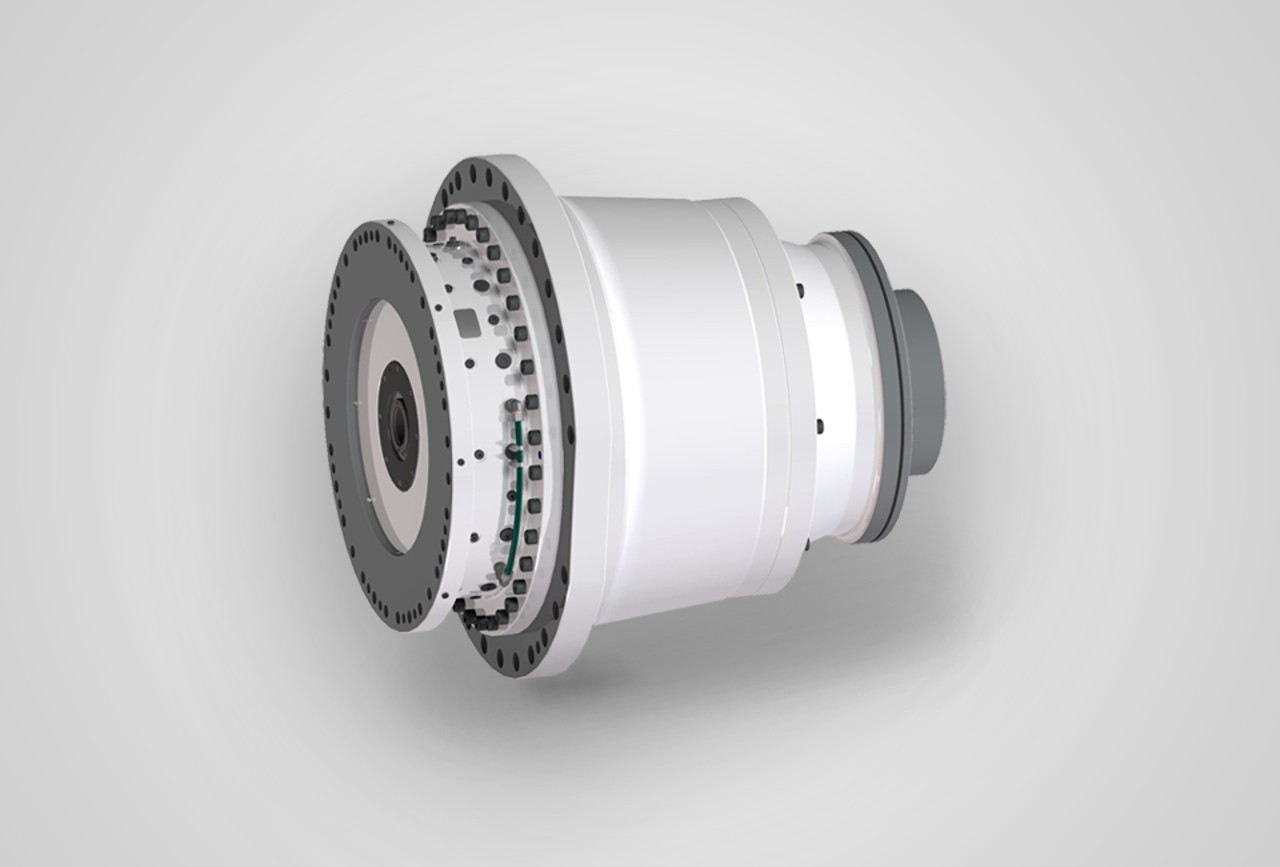

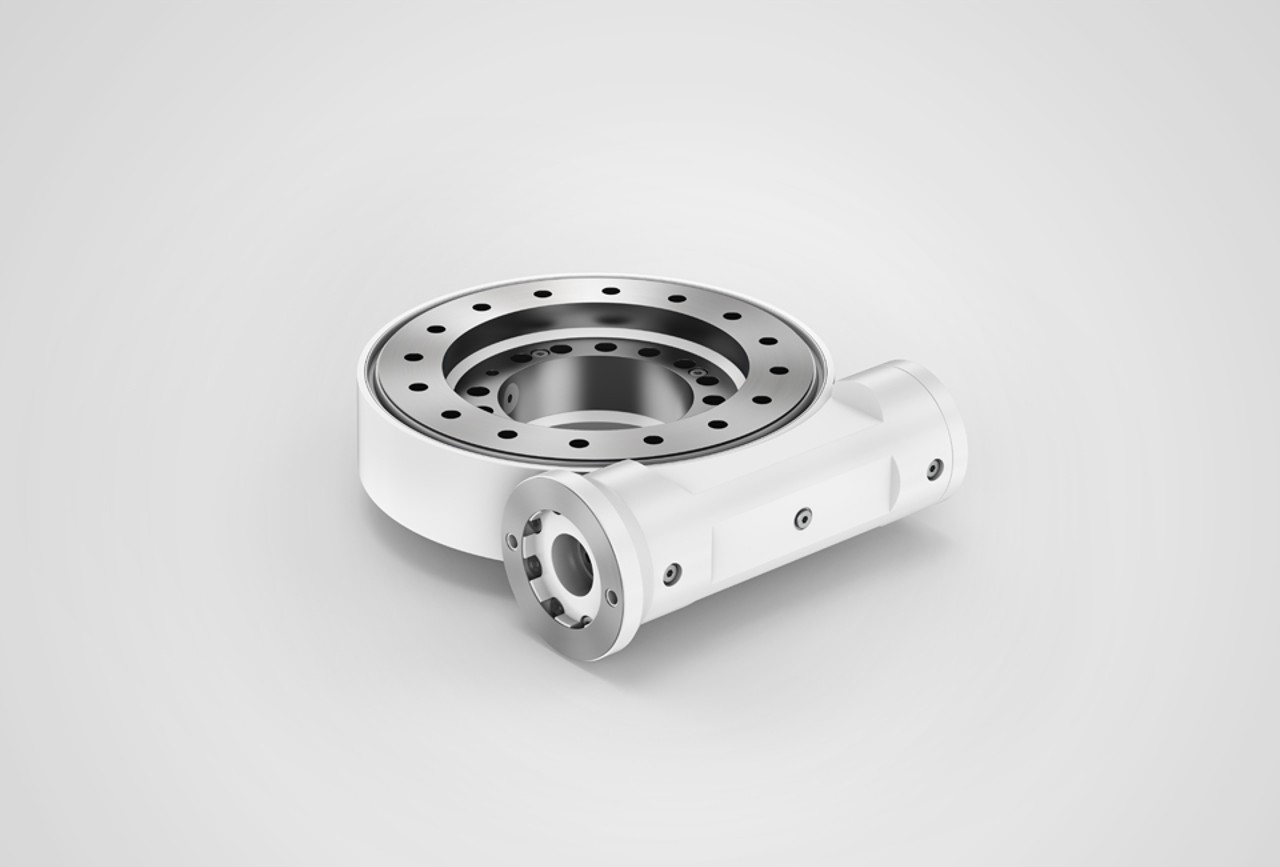

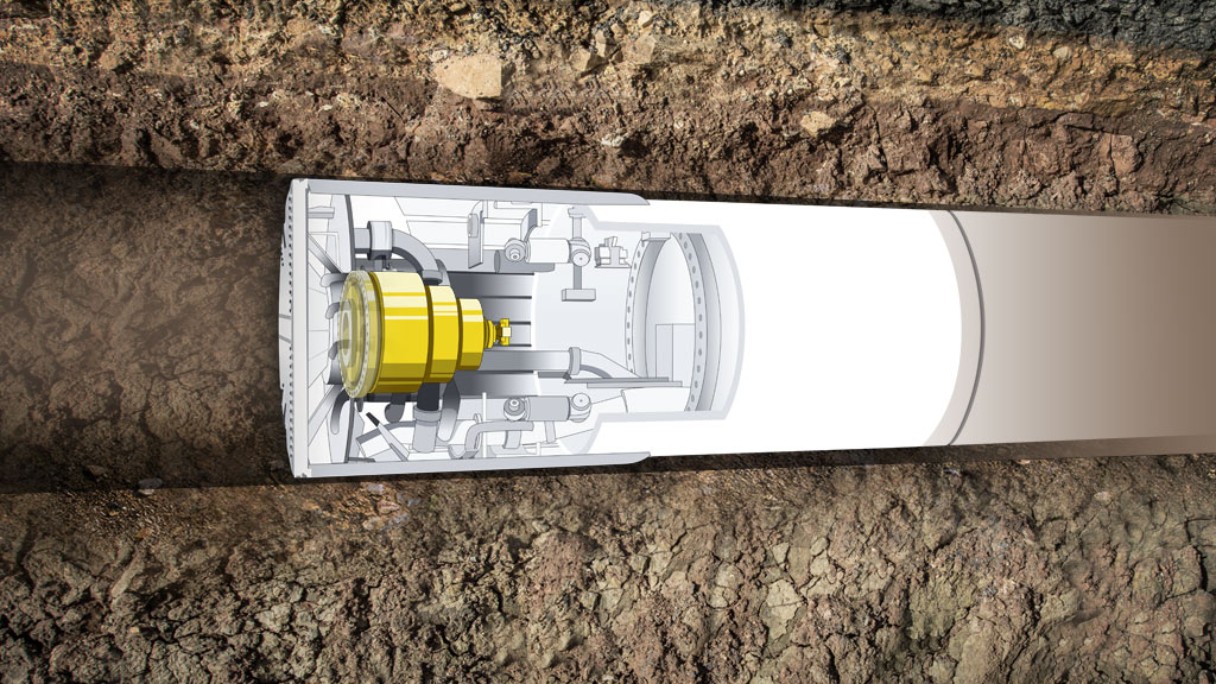

Like a large-diameter worm: Components for micro tunnel boring machines

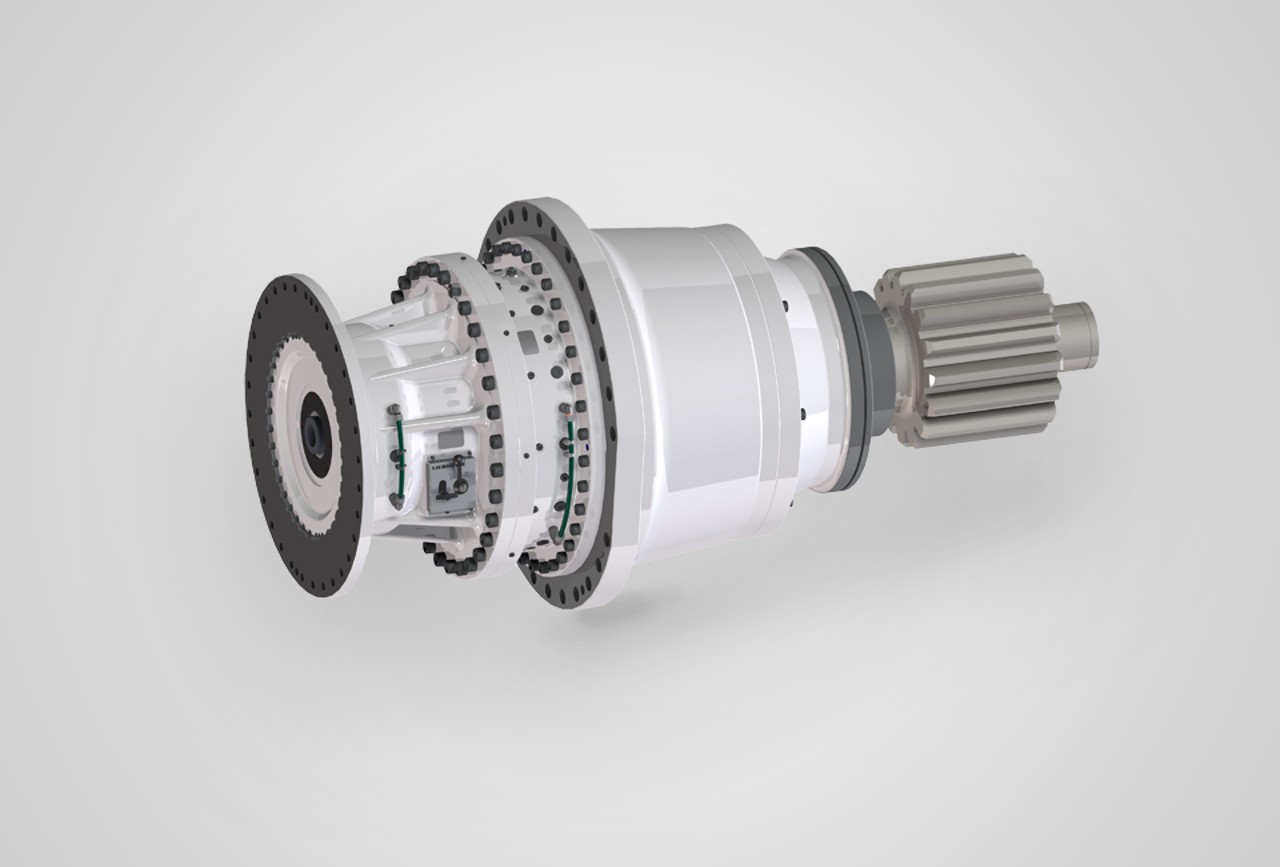

Make your TBM even better with innovations from Liebherr