Gold medal

for sustainability

With this award, Liebherr-MCCtec GmbH ranks among the top 5% of all rated companies and within the top 3% of manufacturing companies worldwide.

EcoVadis is the world’s most credible supplier of business sustainability ratings with over 75,000 companies participating.

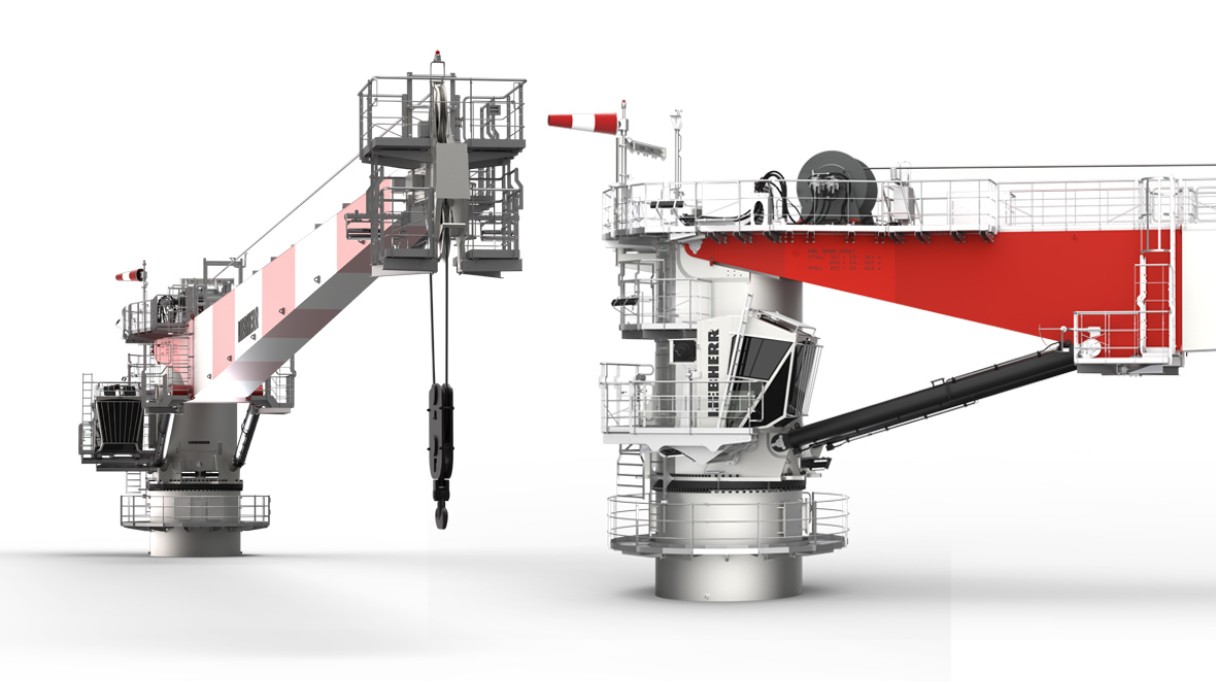

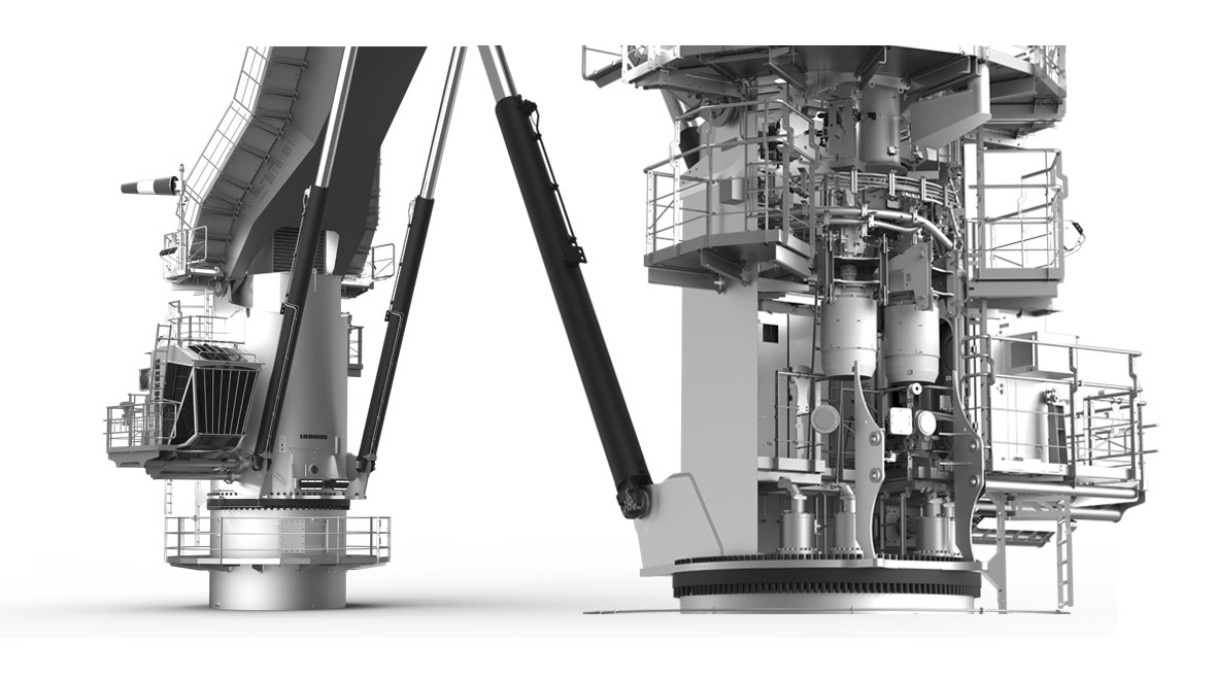

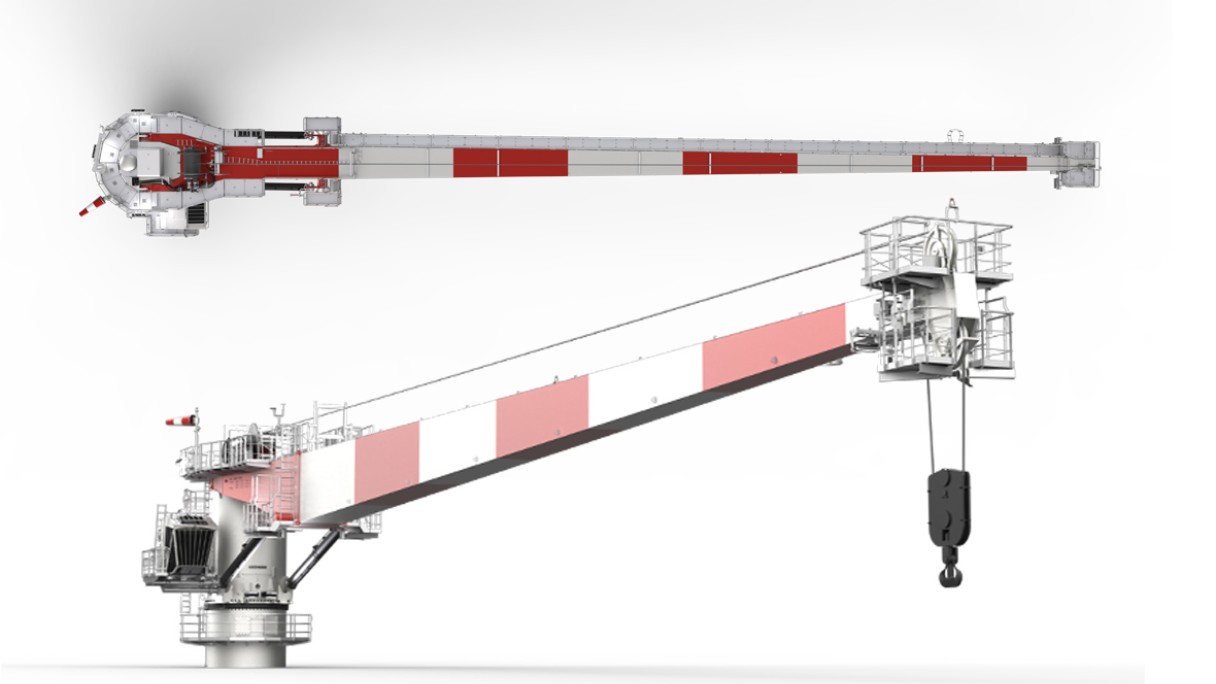

Next generation of RL series

The Liebherr crane specialists have designed a compact and versatile solution to shape the future of offshore maintenance processes. A new approach advances the ram luffing crane (RL) series to meet the future demands of worldwide offshore customers and their individual specifications. A consistently expressed customer preference is to achieve the most compact design possible with a small radius and low overall height. Find out what the new RL has to offer in our highlight video and visit the website for more details about the advanced crane series.

New design approach

Maintenance on a new level

Versatility as a basic principle

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).LHM 800 - a hard-to-miss landmark

Veemnatie MV places a new landmark in the Port of Antwerp with the Liebherr mobile harbour crane type LHM 800. The LHM 800 is the first Liebherr mobile harbour crane of this size in Benelux - a hard-to-miss landmark in the Port of Antwerp. With its 64-metre boom, it offers maximum reach for all upcoming bulk operations.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Rhenus Group relies on Liebherr

Rhenus Midgard is replacing a more than 20-year-old Liebherr LHM 320 with a new Liebherr machine. The LHM 420, recently delivered by project logistics specialist Rhenus Project Logistics, will mainly handle breakbulk and containers at the Dradenau Terminal in the Port of Hamburg.

Season’s Greetings

Sign up now!

Stay up to date with our latest product highlights, innovative technologies and exciting jobsites.