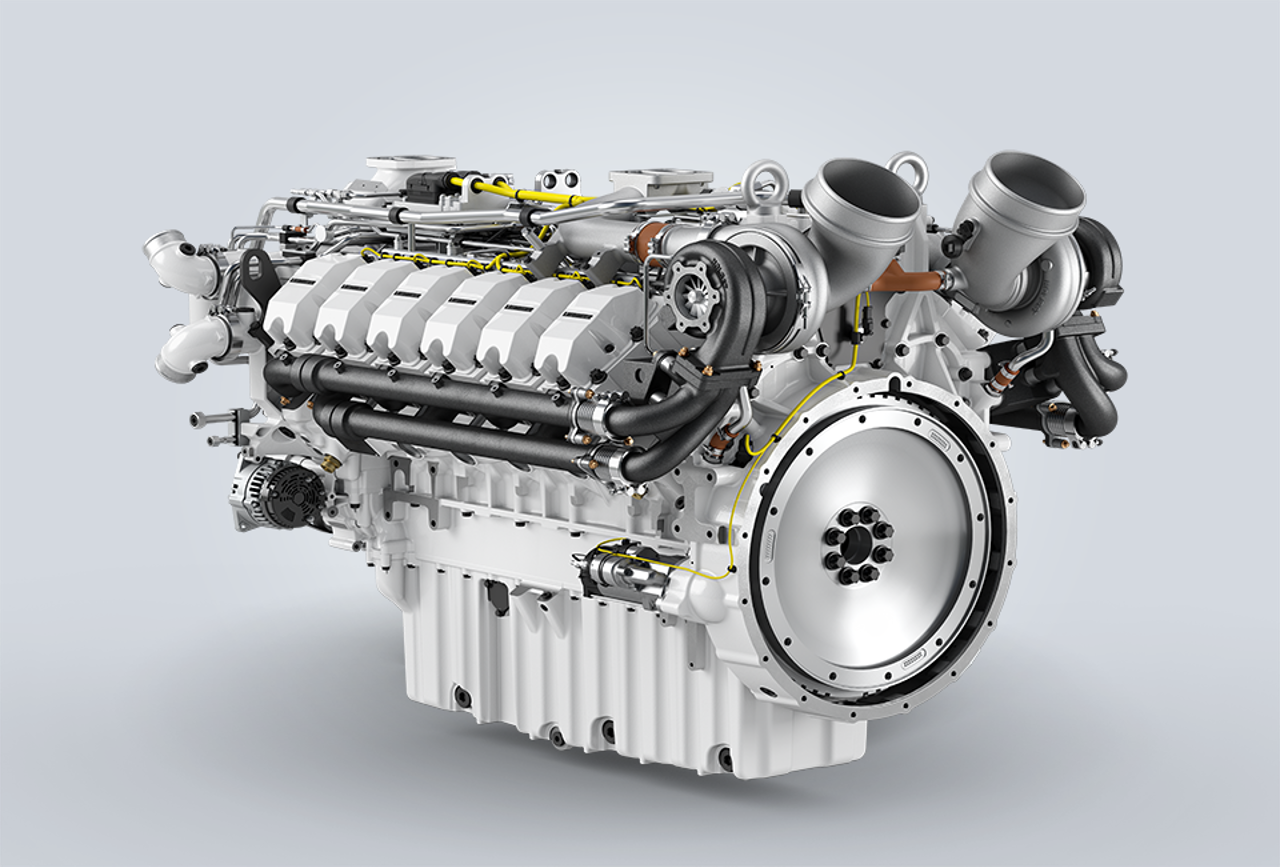

Powerful, efficient, innovative – components for agricultural and forestry machines

With many years of experience in the agricultural industry, Liebherr offers a broad portfolio of components for agricultural and forestry machinery. Components by Liebherr can be used in agricultural machinery covering the entire harvesting cycle. In addition, the range in the forestry sector contains everything from machines for harvesting to equipment for transporting timber.

❯ Combustion engines for tractors, harvesters, and sprayers

❯ Injection systems for tractors, harvesters and combine harvesters

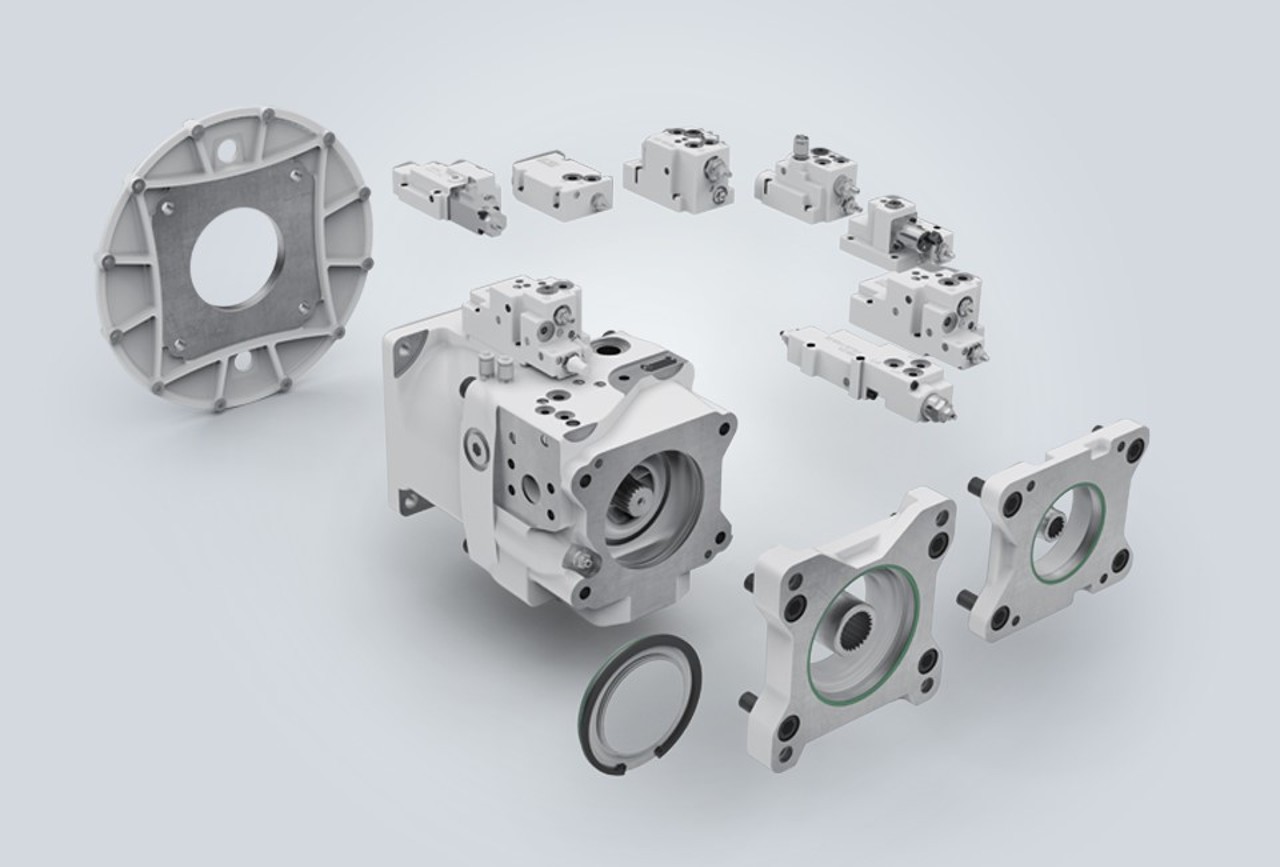

❯ Axial piston pumps and motors for harvesters, sprayers, forwarders and shredders

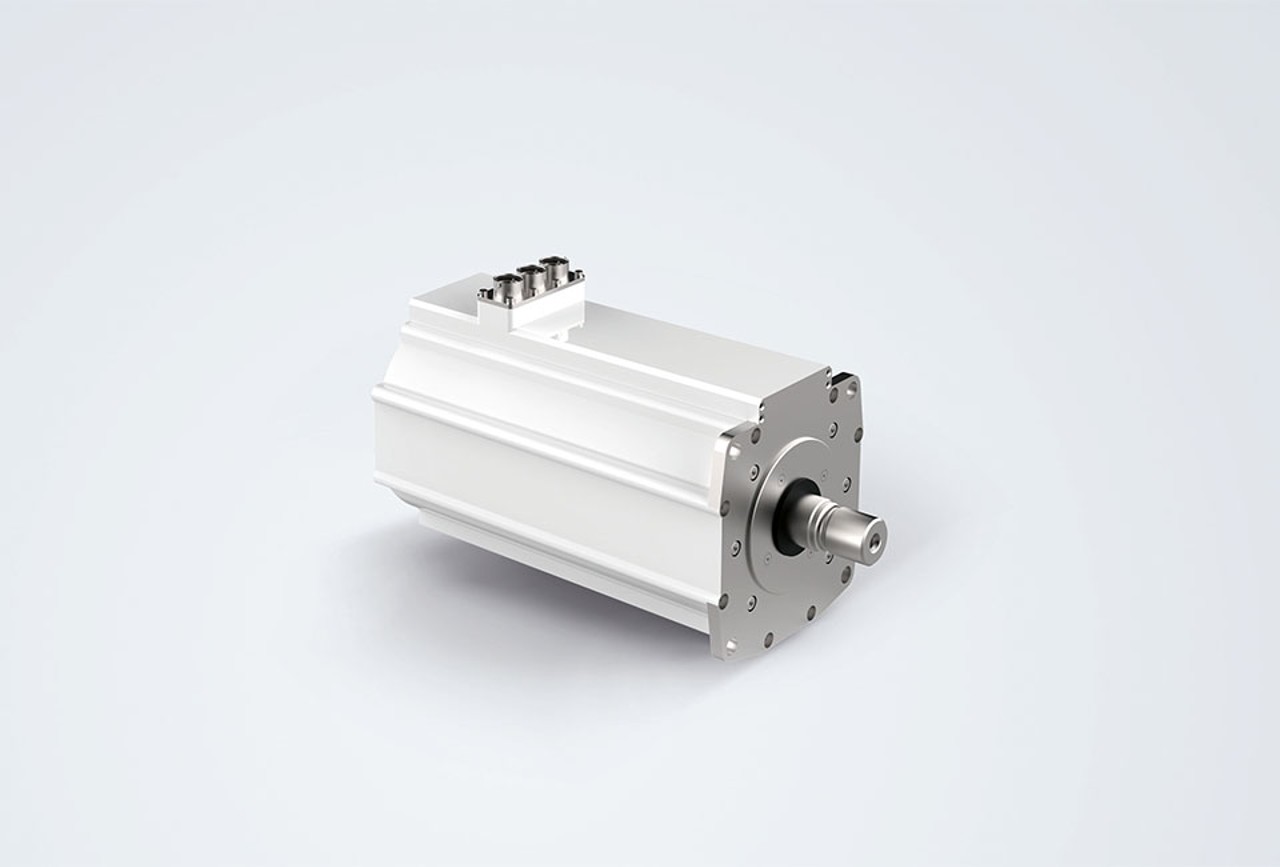

❯ Electric motors for harvesters and tractors

❯ Drive technology for harvesters and farm machines

❯ Slewing bearings and slew drives for harvesters and agricultural machinery

❯ Camera monitor systems and gateway solutions for tractors, harvesters and sprayers

❯ Moisture sensors for combine harvesters, forage harvesters, balers and feed mixers

❯ Energy storage systems for farms and forestry operations

Liduro Power Port – the mobile power supply for electric machines

Charging vehicles and machines with zero local emissions: The mobile Liduro Power Port is a power source for electric vehicles and machines on off-grid sites or sites with limited grid access. It complies to emission regulations and offers long-term investment security with a best price-performance ratio.

Components, systems and products

Durable products thanks to robust design

Long-term experience in various industries

End-to-end product & service portfolio

Modular solutions for easy integration into your ecosystem

With a modular approach, Liebherr's component segment offers you building blocks for your ecosystem - from sensor components to integration into your applications – with the aim of extracting useful data from raw data and adding value to your processes.

_w1280.jpg)