Maritime Cranes Newsletter

Monopiles in the Baltic Sea

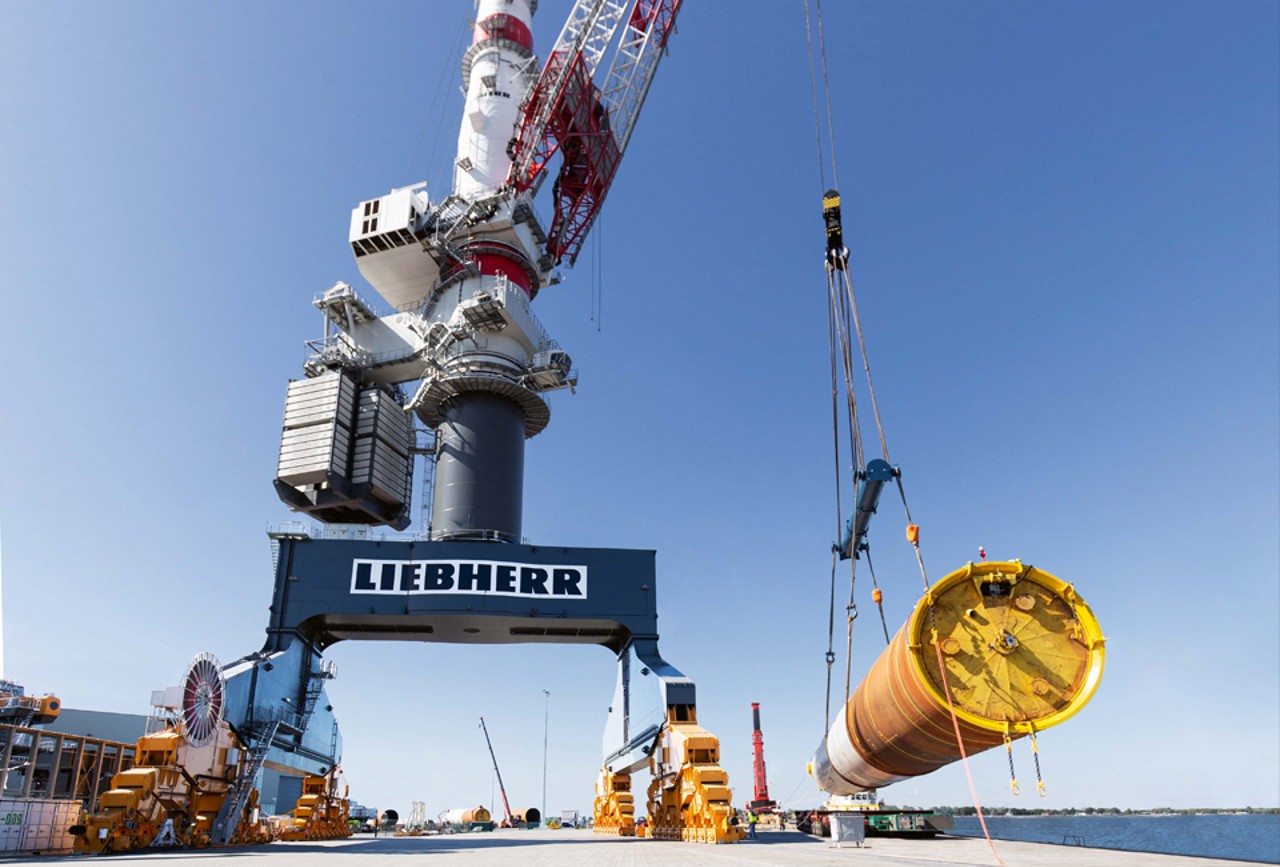

In the port of Rostock, the first monopiles for the offshore wind farm "Kriegers Flak", which is currently under construction, were loaded. The wind farm, located south of the Danish coast, will supply up to 600,000 households with electricity in the future and will thus become Denmark's largest offshore wind farm.

The loading of the monopile foundation piles will be handled by Liebherr's heavy-duty gantry crane type TCC 78000, inaugurated in 2019. The manufacturer of the monopiles is the offshore wind specialist EEW Special Pipe Constructions GmbH, also based in Rostock, Germany.

Monopiles in the Baltic Sea

In the port of Rostock, the first monopiles for the offshore wind farm "Kriegers Flak", which is currently under construction, were loaded. The wind farm, located south of the Danish coast, will supply up to 600,000 households with electricity in the future and will thus become Denmark's largest offshore wind farm.

The loading of the monopile foundation piles will be handled by Liebherr's heavy-duty gantry crane type TCC 78000, inaugurated in 2019. The manufacturer of the monopiles is the offshore wind specialist EEW Special Pipe Constructions GmbH, also based in Rostock, Germany.

Megamax STS underway in Germany

A fleet of six Liebherr STS container cranes are currently under construction in the north of Germany.

The machines are being assembled at Eurogate Container Terminal Bremerhaven before sailing down the river Elbe to Eurogate Container Terminal Hamburg, Germany, where commissioning and installation takes place.

The cranes details:

- Outreach of 65.7 metres

- Backreach of 27 metres

- Lifting height over rail of 53.5 metres

- Span of 18 metres

Partnership enlarged

When there is a demand for outstanding turnover with highest reliability, the Liebherr FCC series is the perfect choice. Many years of experience gathered from the operation of the FCC series have been invested into the development of the new FCC 360. This statement is best supported by customers, who replace and even expand their Liebherr crane portfolio after almost two decades of operation – as our great Indonesian partner Bayan Group did.

For unloading coal barges at the Balikpapan Coal Terminal, three FCC 300 were purchased to replace the existing FCC 300, installed in 2003. To even extend the turnover capacity, two new FCC 360 with an average turnover of approx. 1000 t/h were also delivered to Balikpapan in Indonesia. Get to know more about the Liebherr FCC 360.

Partnership enlarged

When there is a demand for outstanding turnover with highest reliability, the Liebherr FCC series is the perfect choice. Many years of experience gathered from the operation of the FCC series have been invested into the development of the new FCC 360. This statement is best supported by customers, who replace and even expand their Liebherr crane portfolio after almost two decades of operation – as our great Indonesian partner Bayan Group did.

For unloading coal barges at the Balikpapan Coal Terminal, three FCC 300 were purchased to replace the existing FCC 300, installed in 2003. To even extend the turnover capacity, two new FCC 360 with an average turnover of approx. 1000 t/h were also delivered to Balikpapan in Indonesia. Get to know more about the Liebherr FCC 360.

Floating in the Harbor of New York

At the New York Harbor Sims Metal Management uses a Liebherr mobile harbour crane type LHM 600 to load scrap and unload salt. The crane is placed on a floating barge and can be moved to another terminal of the port if required.

With a maximum lifting capacity of 75 tonnes in 4-rope grab operation, the crane is the strongest floating mobile harbour crane on a barge in the U.S. in 4-rope grab capacity.

Floating in the Harbor of New York

At the New York Harbor Sims Metal Management uses a Liebherr mobile harbour crane type LHM 600 to load scrap and unload salt. The crane is placed on a floating barge and can be moved to another terminal of the port if required.

With a maximum lifting capacity of 75 tonnes in 4-rope grab operation, the crane is the strongest floating mobile harbour crane on a barge in the U.S. in 4-rope grab capacity.

Every BOS is a worker

More than 400 Liebherr Board Offshore Cranes (BOS) are in operation in the field at the moment. Offering seven different sizes for a huge variety of applications, our BOS convinces customers around the world for decades with its high reliability and low maintenance.

Besides, the continuous improvement and expansion of the service network is part of Liebherr’s commitment to offering the best possible support around the globe. Read more about one of the most successful products in the offshore crane segment.

Every BOS is a worker

More than 400 Liebherr Board Offshore Cranes (BOS) are in operation in the field at the moment. Offering seven different sizes for a huge variety of applications, our BOS convinces customers around the world for decades with its high reliability and low maintenance.

Besides, the continuous improvement and expansion of the service network is part of Liebherr’s commitment to offering the best possible support around the globe. Read more about one of the most successful products in the offshore crane segment.

Every BOS is a worker

More than 400 Liebherr Board Offshore Cranes (BOS) are in operation in the field at the moment. Offering seven different sizes for a huge variety of applications, our BOS convinces customers around the world for decades with its high reliability and low maintenance.

Besides, the continuous improvement and expansion of the service network is part of Liebherr’s commitment to offering the best possible support around the globe. Read more about one of the most successful products in the offshore crane segment.

Fuel costs matter

The Liebherr reachstacker offers enormous savings potential in terms of diesel consumption due to its innovative hydrostatic drive system and the resulting smaller engine size. In addition, the hydrostatic drive also eliminates the need for heavy-weight and maintenance-intensive components, like the torque converter, driving axle, gearbox and differential.

Try out our fuel savings calculator and discover your saving potential.

Remote Service App

Liebherr expands its digital product portfolio with the development of a Remote Service tool. This improves assistance through visual information and so leads to faster and easier troubleshooting.

Due to the current pandemic situation worldwide, Liebherr has decided to accelerate the market launch of Remote Service in terms of an extended test phase. This means all Liebherr customers now have the opportunity to use the Remote Service App free of charge until the end of 2020.

A laptop, tablet or smartphone and an internet connection are all that are needed.

Exhibitions & Events (subject to)

Intermodal South America

Find out more

5th Baltic Ports & Shipping

Find out more

Breakbulk Europe

Find out more

Adipec

Find out more

TOC Americas (virtual expo)

Find out more

9th Black Sea Ports & Shipping

Find out more

Offshore Energy

Find out more

Breakbulk Americas

Find out more

International Offshore Crane and Lifting Conference

Find out more