Process reliability from automation

A range of different materials and methods are applied in dosing and adhesive bonding applications for battery pack assembly. Applying heatconducting paste in the battery tray and sealing the battery pack cover demands complete process reliability – any rejects at this stage become expensive. At the test facilities in the Kempten Tech Center, Liebherr-Verzahntechnik GmbH tests the automation for adhesive bonding and dosing applications and, from a single source, offers customer-specific applications providing process reliability.

Dosing occurs at two points in battery pack assembly. Firstly, a heat-conducting paste – the gap filler – is applied to the base of the battery tray before inserting the battery modules in order to ensure heat dissipation. In the ‘sealing’ stage, the battery system housing is finally sealed. Precision and process reliability are essential as errors at these points can have serious consequences.

Thermal management

In high-voltage battery systems, thermal management has a critical role to play in extending the service life of the batteries and ensuring their safety and efficiency. Without effective heat dissipation, the temperature inside the battery pack can rise uncontrollably. Overheating can trigger thermal runaway resulting in fires and explosions. The increased operating temperature can also accelerate battery cell aging and shorten the service life of the battery pack. Gap filler or thermal interface materials (TIMs) therefore ensure heat is dissipated from the battery modules and cells into the cooling system. Its application in liquid form achieves an optimal coating and improved thermal connection between the heat source and heat sink. Gap fillers or TIMs must be applied precisely and with no formation of air pockets. This is the only way to ensure effective thermal transfer in order that the electronics and battery cells can function safely and in a durable manner within the optimum temperature range.

Sealing the housing

High-voltage batteries must be completely sealed to ensure their performance, durability and safety and to protect them from environmental influences. Moisture, dirt and contaminants can impair the batteries and shorten their service lives. Complete sealing also prevents environmentally harmful electrolytes from escaping. Housing seals can also be applied in the form of hot glues – in most cases hot butyl. These also provide a quick, efficient and complete seal with high temperature resistance on uneven surfaces.

Challenges in the process

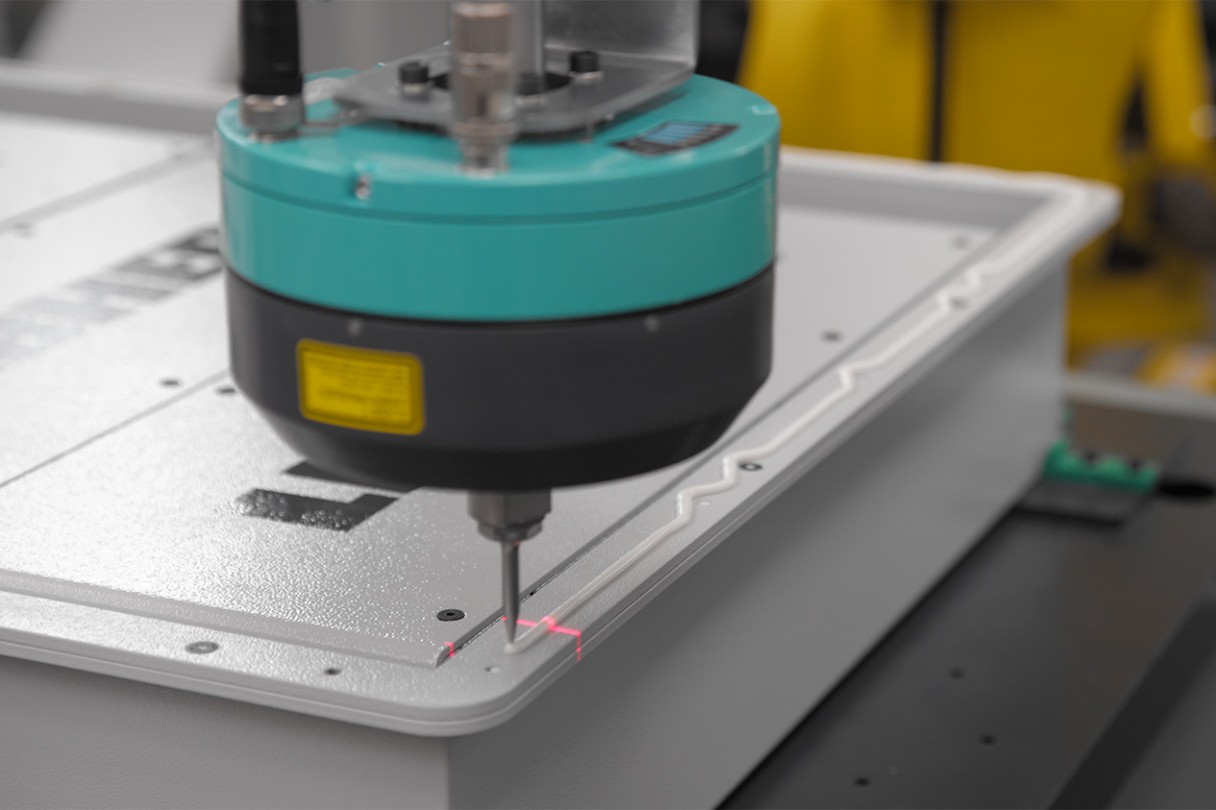

When dosing, exact lines of liquid adhesive and clean bead transitions are vital for ensuring quality. Irregularities in the dosing bead can impair the performance of the seal. When applying material, the challenge is therefore generally to maintain control via the dosing parameters. This ensures an even application throughout the entire dosing process.

Dosing the housing sealant on the sealing surface of the battery pack

Key aspects of dosing

Liquid dosing using one- or two-component media is a delicate process subject to external influences such as temperature deviations. The different material properties in terms of viscosity and curing characteristics must be taken into account from removal to mixing at the dispenser and when calculating the bead paths. When applying the heat-conducting paste on the base of the battery tray, the optimal application pattern is also important for ensuring sufficient coating of the base, preventing air pockets and also for optimal consumption of the expensive material. Pre-treatment methods and activation of surfaces also contribute to optimal adhesion.

Precise application of the heat-conducting paste (gap filler) on the bottom of the battery tray

New: removable tape seal

An innovative alternative to sealing using liquid adhesives is the ACXplus 76730 Box Seal bonding application from tesa, an international manufacturer of innovative tapes and self-adhesive product solutions. The tape requires no curing time and has high compressibility. This also enables large gaps to be filled and sealed. Liebherr offers this application in cooperation with tesa and the tape application experts Vulkan Technic. “The cover can be opened without being destroyed which means the tape can be removed without any residue. This is not just an advantage during production for reworking in the plant, but also for subsequent disassembly in second-life applications or in recycling,” explains Viktor Bayrhof, Product Manager for Automation Systems at Liebherr-Verzahntechnik GmbH.

Overview of methods on the market

“With the large number of methods on the market, it quickly becomes difficult for users to keep track, in particular when weighing the pros and cons and the costs,” explains Bayrhof. Liebherr offers all adhesive bonding and dosing applications for battery packs including the necessary process monitoring. To support this, Liebherr conducts extensive validation at its test facilities in the Kempten Tech Center. This means the company is able to provide its customers with competent advice when choosing the appropriate method. As one of the world‘s leading manufacturers of automation systems, Liebherr also has an overview of manufacturing plant components and peripherals. “For customers, the advantage is getting everything from a single source and no longer having lots of individual contact partners,” emphasizes Bayrhof.