Litronic-FMS 3K evaluation module

A self-sufficient moisture measuring installation with high connectivity and many interesting possibilities. The FMS 3K, the successor to the FMS III Box PC, offers comprehensive signal processing making it a good partner for a modern industrial solution.

At the beginning of each measured section, the calibration per product must be carried out by means of reference procedures. The Litronic-FMS 3K software enables convenient and rapid parametrisation.

The evaluation unit receives the raw values measured by the Liebherr sensors and immediately converts them into the measured value, such as percentage humidity.

Up to 4 sensors can be managed via one device. A curve manager and material and sample management helps the user to create the product-specific calibration.

Once the system has been calibrated, further measuring points can be set up or devices renewed on this basis at any time without great effort. The plant thus always remains reliable, regardless of its previous term and age.

In addition to their high precision and robustness, the measuring devices from Bad Schussenried are characterised by their reproducibility. A sensor replacement or a transfer to another measured section is also possible without recalibration.

| Measuring cycle of the evaluation | up to 30 measurements per second |

| Measured value output | optional: analog 0 (4) -20 (24) mA, 0 -10 V DC , etc. |

| Measuring range | Measuring window can be parametrised as desired |

| Supply voltage | 12-24 V DC |

| Temperature range | -25 to +55 °C |

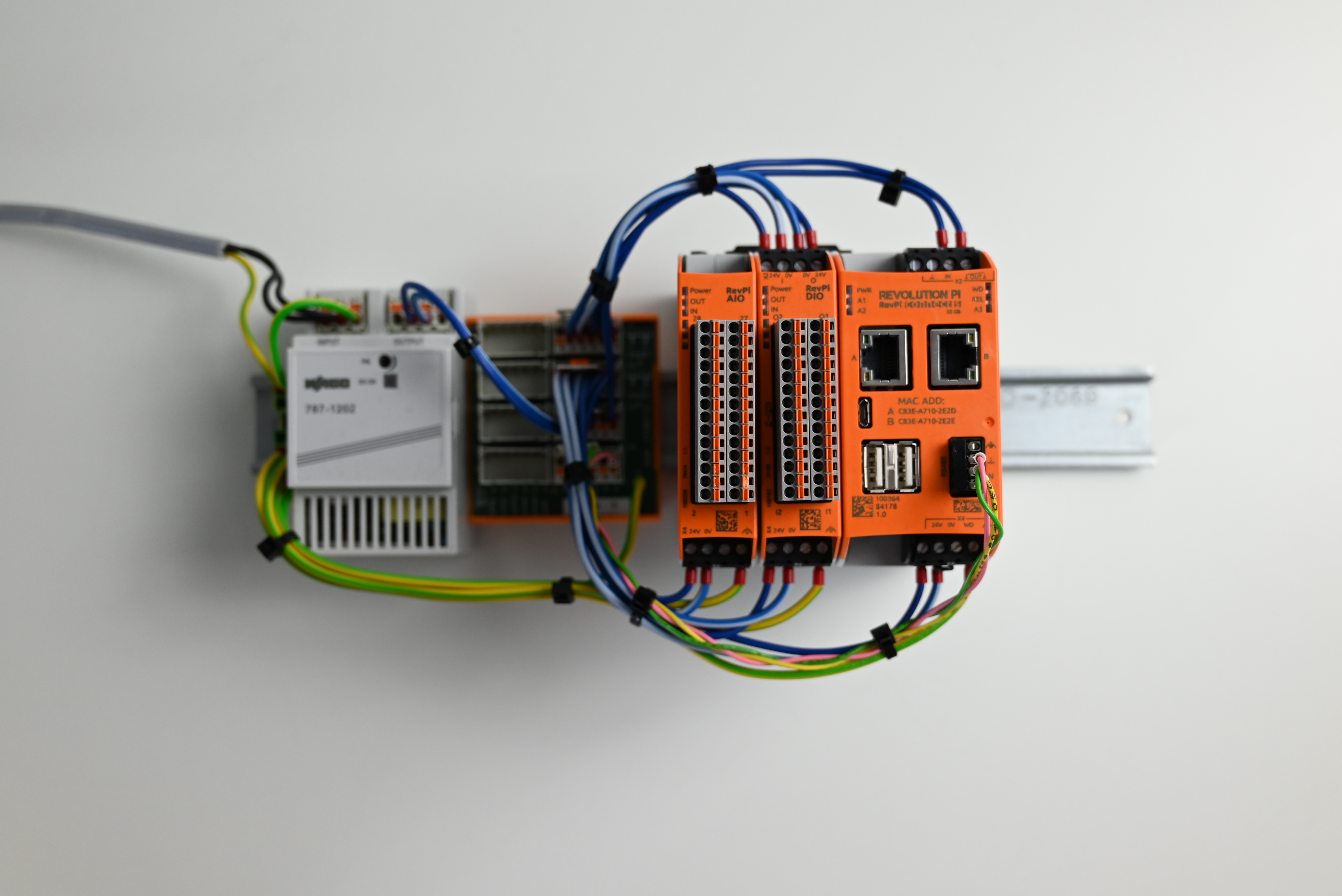

| Evaluation unit | Broadcom BCM2711, 1,5 GHz with Quad-Core-Prozessor Arm Cortex-A72 1 x Display-Ausgang: 1 x Micro HDMI 2.0a (4K) 1 x DVI-D, 1 x DisplayPort 2 x RJ45 10/100 Ethernet (with independent MAC Adresses) 2 x USB A 1 x RS485 Screw clamp connection 1 x Micro-USB socket 1 x PiBridge Systembus 1 x ConBridge Systembus |

Functions

- Connection and addressing of 1 to 4 Litronic streaming sensors

- Alternatively: Connection of a bus cable for bus connection box

- Interface converter RS232 / sensor bus RS 485 integrated

- Overvoltage protection

- Current limitation at short circuit

- DIN rail mounting

- Assembly on standard TS35 mounting rail for simple switch cabinet mounting

Characteristics

- Parameterization and calibration via integrated software

- Different operation modes available

- Channel bundling, Filter, individual adjustments

- 2x Ethernet connection

- Modular design for easy system extension

- Mounting on standard mounting-rail TS35 for simple mounting on switch cabinet

Indirect measuring method: Capacity determination in the high frequency stray field. This method uses the different dielectric constant (permittivity) of water and different materials (solids and liquids)

Fully reproducible sensors: If the plant is subsequently extended with sensors or if sensors are replaced, no recalibration is necessary thanks to the built-in microprocessor.

Multiple measuring points: Up to 4 sensors can be connected to one evaluation unit.

Modular: If required, the FMS 3K can be expanded with further modules such as digital inputs and outputs, analogue outputs such as 0-10 V/4-20 mA, etc.

Well stowed: The evaluation unit is mounted on a TS-35 top-hat rail and can thus be installed in the switch cabinet.

Process control and regulation: Thanks to extensive interfaces, the moisture measurement can be integrated into process control systems and controls.

Limit values: Maximum or minimum limits can be set using the software. Light or sound signals can be triggered if required.

Mean value calculator: The FMS 3K receives the signals from the sensors and can output already averaged values to a higher-level control if required.

Software: The Liebherr FMS 3K software integrated in the system is available for visualization, configuration, measured value recording and calibration.