Your application is our mission: We are there when you need us.

Over 20,000 slewing bearings leave our plants every year. And, relying on 70 years of experience in the construction of slewing bearings, we form the competent partner our customers need in engineering and production. For our customers, we are here to assist worldwide with comprehensive services for our slewing bearings. Our standard ranges from our own calculation models to state-of-the-art quality management to easy-to-use grease analysis kit.

Packaging and storage

Fully enclosed, sealed and heavy-duty protection for slewing bearings

The slewing bearings are packed according to the requirements. Liebherr offers various types of packaging, such as boxes made of high-quality and heat-treated hardwood and VCI film with suitable preservation for safe shipping.

Multiple use packaging: Environmentally friendly, lower carbon footprint

It is also possible to use a circulating packaging, if requested. This kind of packaging is designed to pack and transport slewing bearings repeatedly. The multiple use contributes to a greener environment.

Transport pallet

The slewing bearings can be packed on a special transport pallet. This can be flexibly transported with a forklift truck. On request, they can also be packed in VCI film – depending on the coating, transport duration and transport route.

“Stackable” load-bearing box packaging

The packaging is designed to carry the full weight of the slewing bearing. The selected lifting device can be placed around the box at the marked points. In addition, it is possible load and unload the box by means of a forklift truck

Carry-along box packaging

The handling of the packaging takes place via the lifting points directly fitted to the slewing bearing. In order to save storage space, the boxes can be stacked. With different designs and sizes, Liebherr also offers a lightweight variant of this type of packaging.

Combined box packaging

This packaging combines the features of a carry-along and a load-bearing packaging. The box is designed for transport by forklift and sling around the box. In addition, attaching slings directly to the lifting points on the slewing bearing is possible, optimally also stacking of the boxes.

Long-term storage packaging

By adding additional desiccant and special VCI wrapping, it is possible to pack slewing bearings on a long-term basis. With an additional humidity indicator, the climate and relative humidity inside the packaging can be read.

Storage: Protected from environmental influences

Liebherr offers various conservation options to protect the slewing bearings from corrosion. A standard conservation can be between 3 and 6 months.For shipping overseas or planned storage slewing bearings can be conservated up to 36 months.

Additionally, a protected storage solution environment without high temperature fluctuations can contribute to a longer storage life.

Transportation for large slewing bearings

The transportation of slewing bearings in particular is a logistical masterpiece by because of their dimensions. Numerous challenges due to infrastructures must be considered nationally as well as internationally.

Because of their dimensions and weight, slewing bearings often place high demands on transportation company. If horizontal transportation of the product is difficult for logistical and/or road transport circumstances, Liebherr offers alternatives suitable for everyday use. These include diagonal or vertical loading with the aid of skids, as well as special equipment made from wood, plastic or metal, which ensure smooth transportation.

Organized transportation for all around the world

Liebherr's shipping and logistics experts organize national and international transport by truck, overseas vessel and air freight. Since the transport is customized according to the delivery location, the Liebherr team develops a transport strategy during the quotation stage. The work with strategic suppliers in the transport and packaging sector, makes it possible to deliver the slewing bearings to various countries around the globe.

Lifted the right way

Liebherr mobile cranes are a big helper when it comes to lifting our slewing bearings the right way. During crane transportation the slewing bearings must always be moved using suitable hoists and lifting gears. These must be secured to the intended transport lifting holes (Points) with suitable lifting eyes. The number and arrangement of the lifting eyes are defined during the project planning stage.

Safe and secure

For Smooth transportation, specially trained experts take care of a safe transport and conduct multiple checks of the packaging and load securing. Due to the fact that each transport is planned precisely, individual steps are documented for transparency. In addition, our experts take care of the necessary infrastructure. This also includes the general transport organization for our slewing bearings, as well as potentially necessary police escort or even the approval for special routes and the roads.

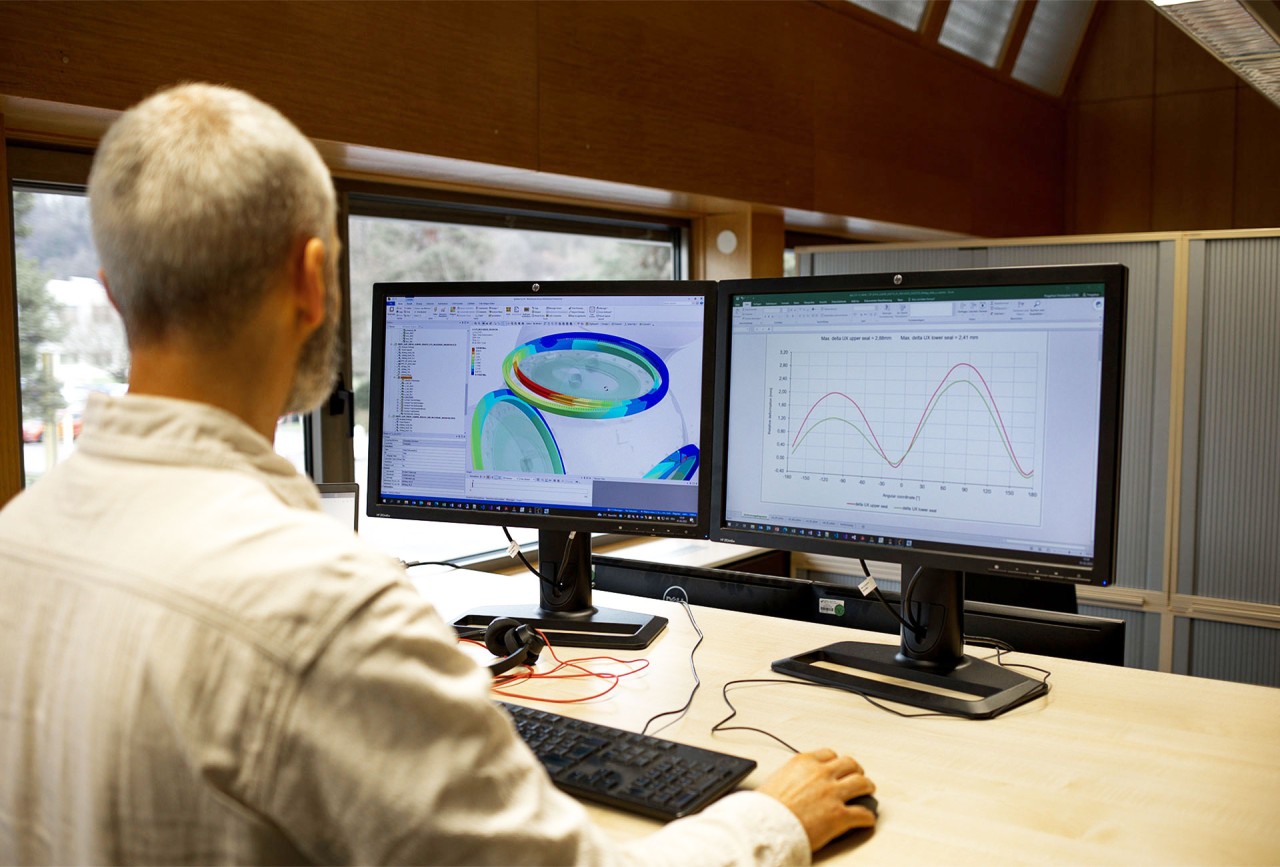

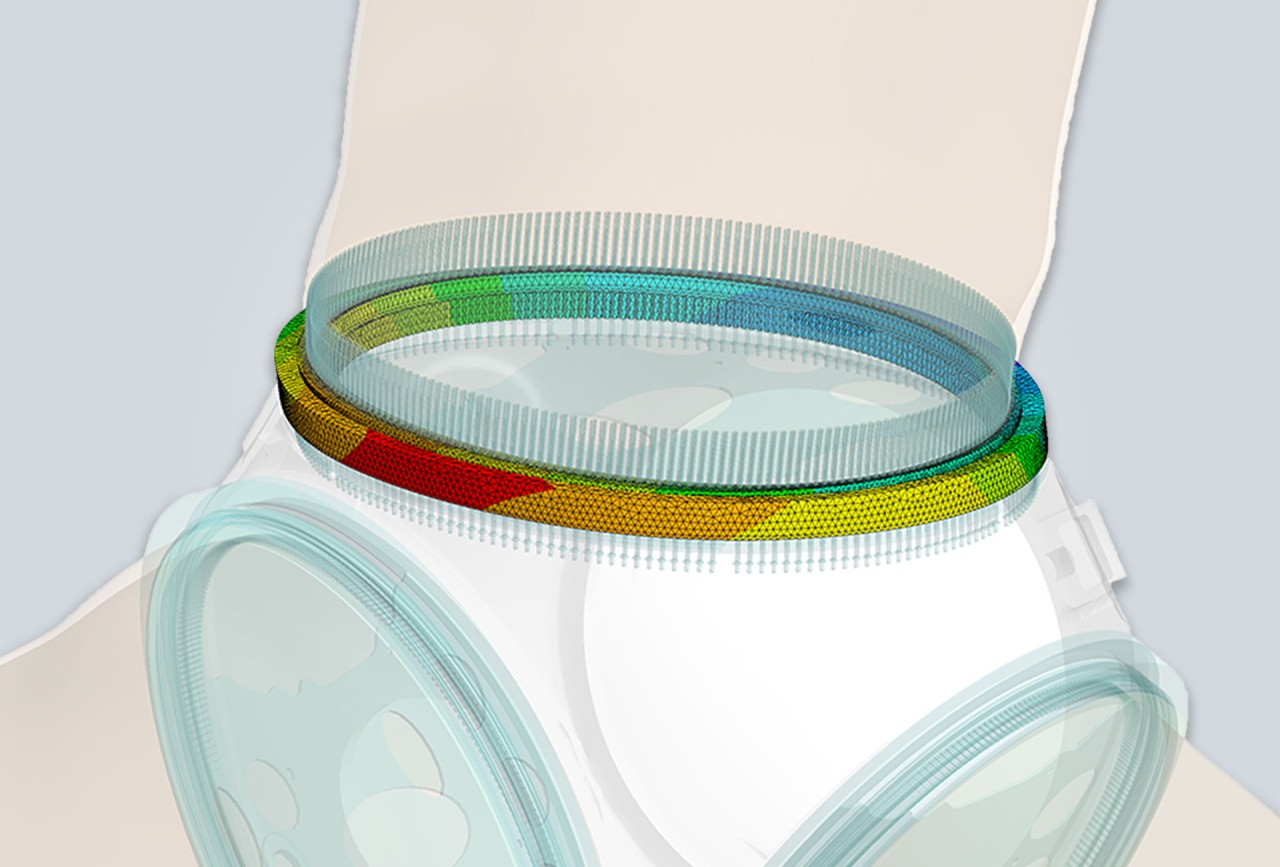

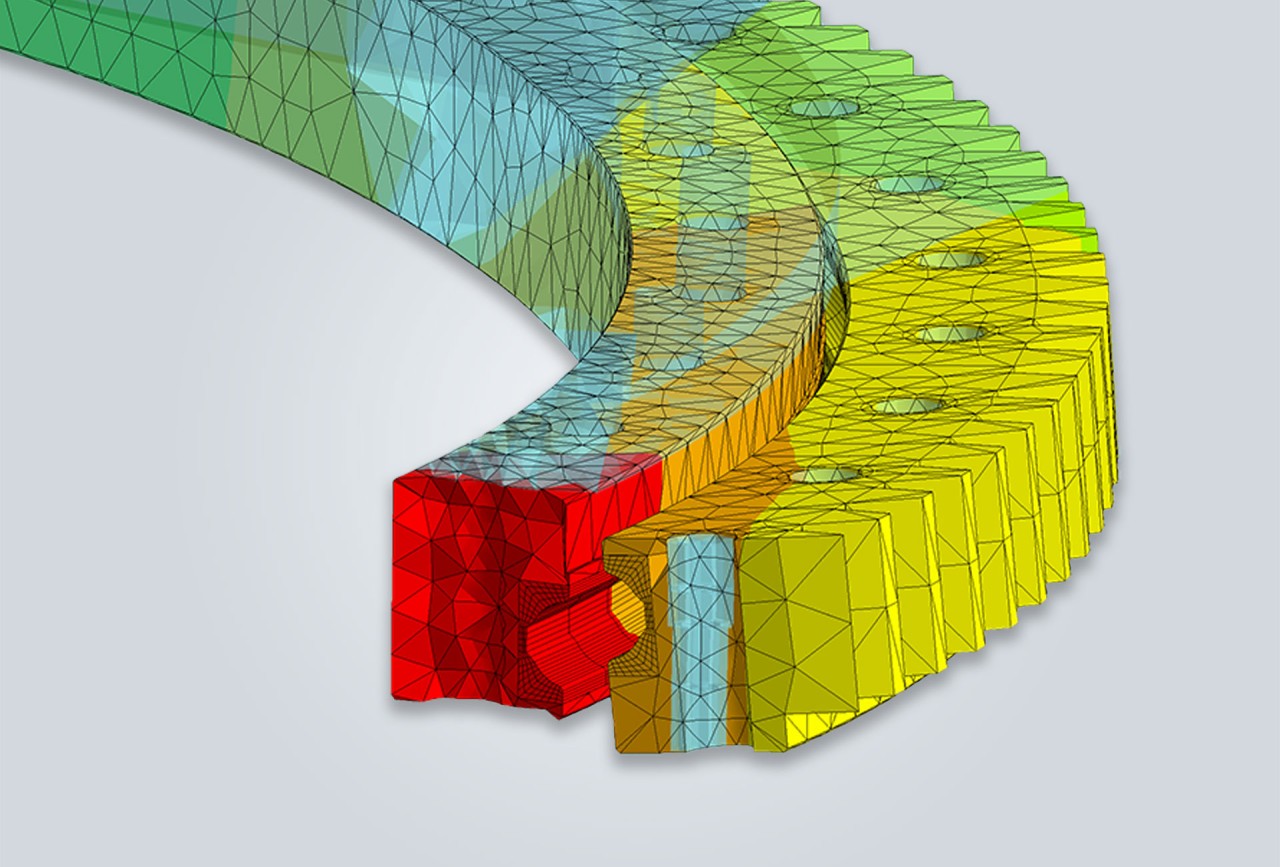

Finite Element Analysis: Component design and calculation

Accurate calculations for absolute reliability in your application

To ensure maximum safety and a long service life of the slewing bearings , various load cases and specific requirements are calculated using the finite element analysis as early as the development and prototype phase.

Customers always benefit from the complex and long-standing know-how of the FEM-specialists at Liebherr. Our specialists are on hand as a reliable development partner and responds to individual requests.

Safety for your application. Right from the start.

Taking into account the application-specific companion structures, the slewing bearings are checked for various load cases using the FE Analysis calculation. This makes it possible to prevent unwanted influences based on the companion structure with regard to ring stresses and bolt stresses as well as deformations leading to leakage and to maximize safety for customers and their application.

For the big picture. Calculated in every detail.

Liebherr slewing bearings are calculated within the FE Analysis with all the necessary details. This results in various outcomes such as:

- Load distribution in slewing bearings

- Pressure distribution in all rolling elements

- Verification of static and dynamic load carrying capacity of bearing rings, bearing raceways and screw connections

- Edge hardness depth

- Behavior at the contact joints

- Deformations at the sealing gaps

- If required by the customer: Stresses and deformations in the adjacent construction

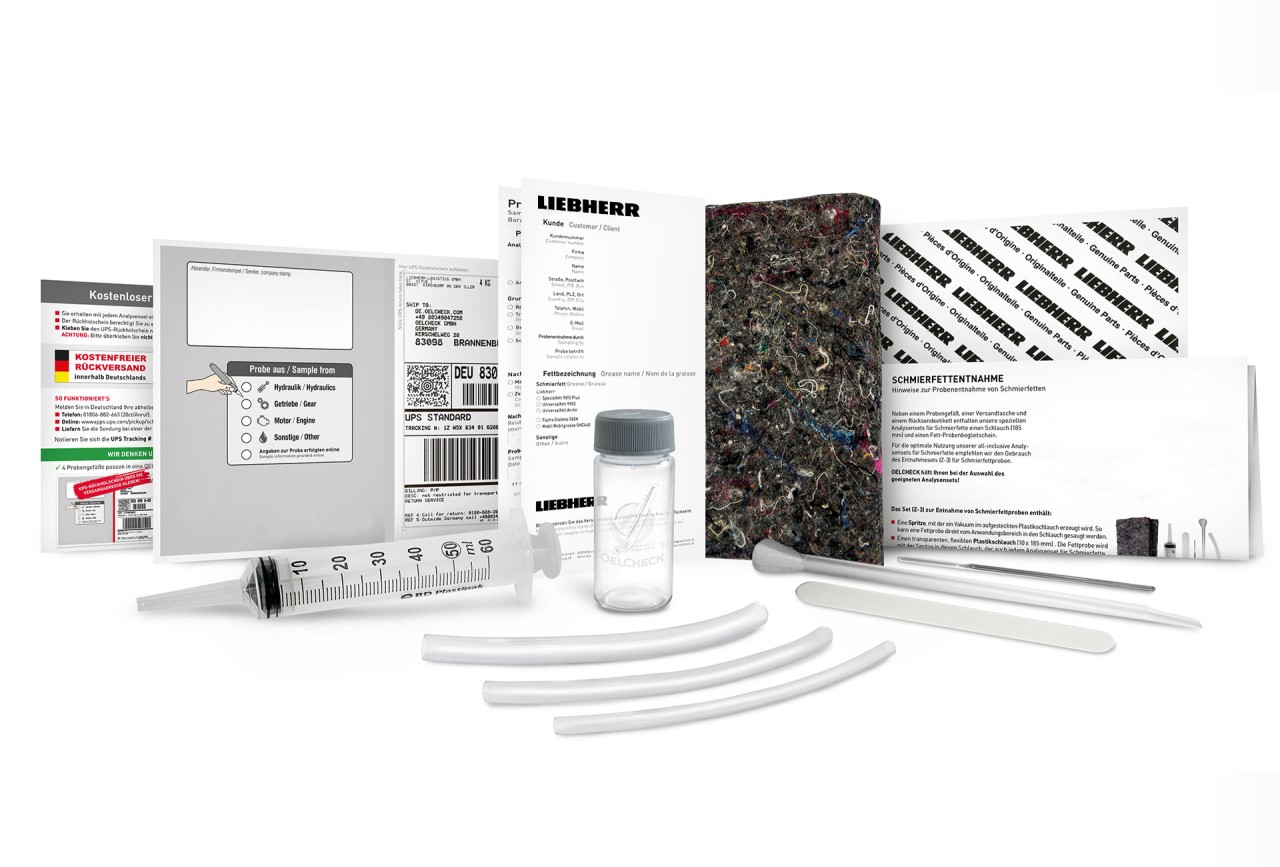

Grease analysis kit: grease sampling for slewing bearings in field use

Analysis with specific limit values set by Liebherr

- Liebherr limit values for a higher quality statement about the grease condition of the slewing bearings

- All-inclusive grease-analysis-kit: complete measurement accessories, instructions, return envelope and return label

- Fast evaluation within 2 – 4 days

- Execution of various tests, such as particle test, oil bleeding test, test for non-ferrous metals, test for organic substances

Scope of examination: Liebherr grease analysis kit

Scope of examination: Liebherr grease analysis kit

- Expertise: Evaluation of the grease sample and, if necessary, on-site assistance regarding endoscopy, tooth flank clearance, sealing examinations, visual inspection, dentures

- Solution provider: Seal kits, completely new bearings or overhaul of bearings

- Element analysis with AES for the determination of wear metals, additives, impurities

- Base oil condition by FT-IR spectroscopy

- Sample image / visual assessment

- Magnetic metal abrasion as PQ index

- Water content in ppm according to Karl Fischer

- Residual oil content

Approved quality: certifications

The numerous certifications are testament to Liebherr's high standard of quality. Aside from the usual ISO standards of the quality management system, Liebherr has the following certifications:

Regular audits and internal company standards

All corporate processes at Liebherr are focused on quality, from the selection of raw materials and suppliers to the after-sales service. Each individual component of the slewing bearing is subject to strict quality requirements. This is why we only work with select suppliers, who are audited on a regular basis. Internal company standards apply to certain raw materials like rolled steel rings. These standards contain requirements, which go beyond the common industry standards.

Sophisticated quality management

Liebherr bearings are characterised by their high quality and reliability. To guarantee and further improve our quality standard over the long term, we document all manufacturing and assembly processes in a production data acquisition system. This also serves as a central quality management system for production and assembly measurements, thus allowing comprehensive control, monitoring and tracking; deviations are quickly eliminated, and processes are constantly optimised.

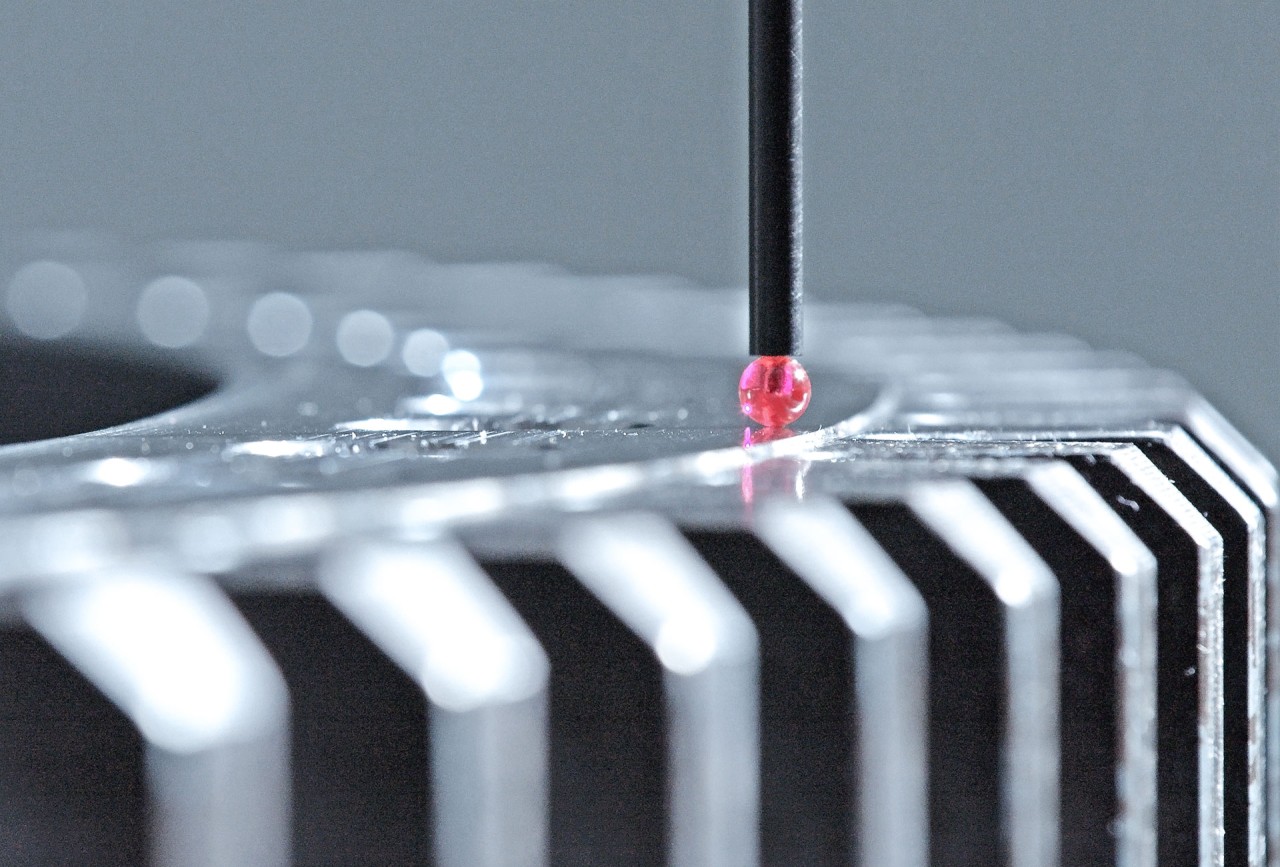

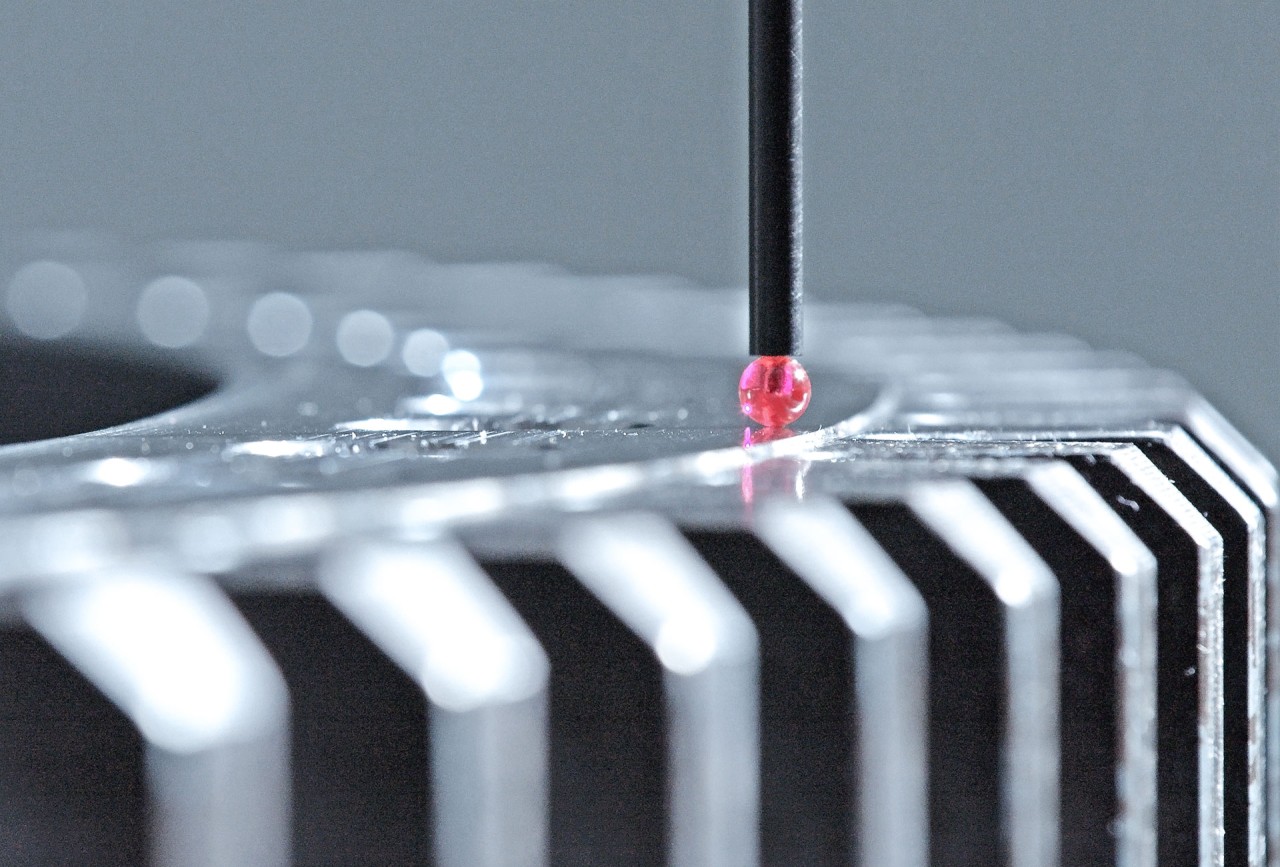

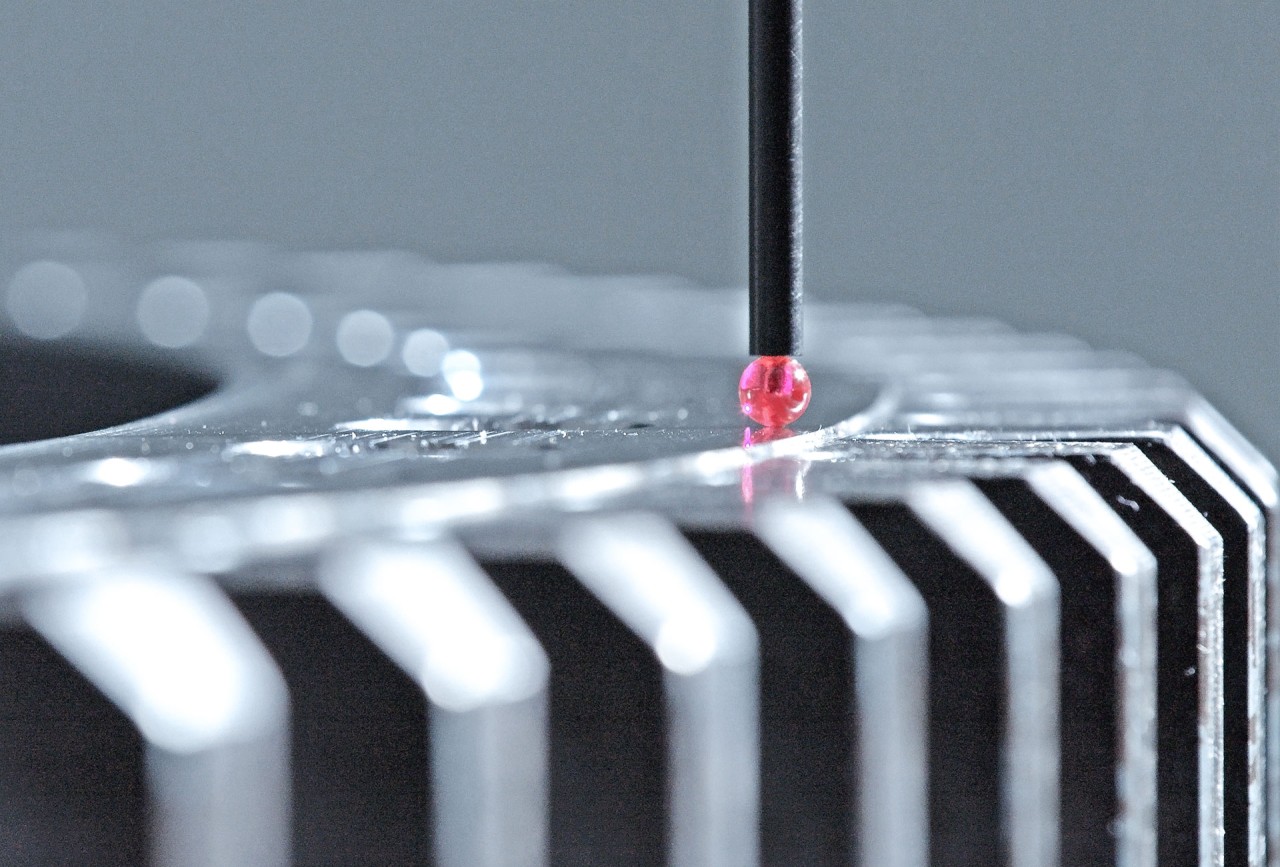

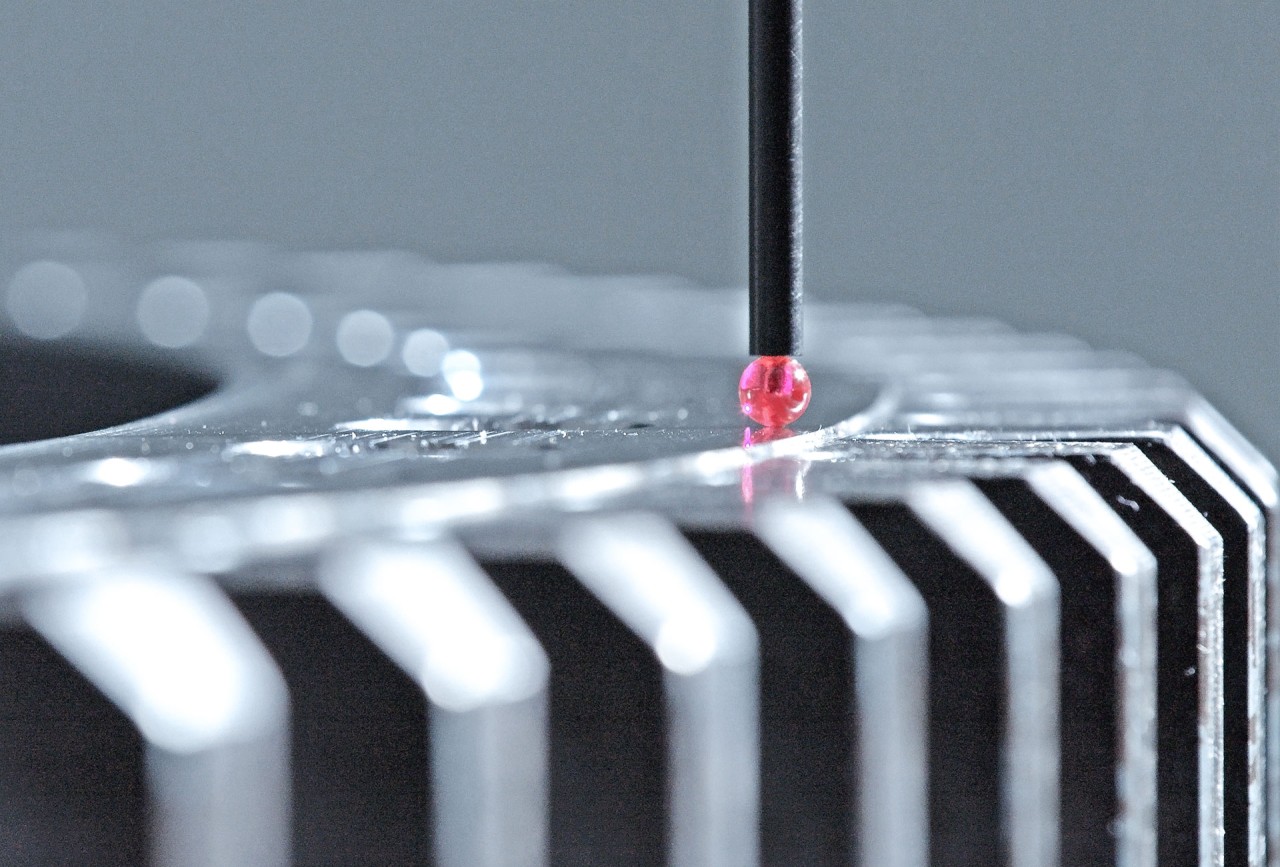

Ultramodern measurement methods

Liebherr not only makes regular use of traditional computer-aided measurement methods. The Liebherr Group also possesses numerous highly specialised measuring devices. In recent years, for example, the company has invested in a state-of-the-art crack detection system using high frequency magnetisation and a fully climate-controlled slewing bearing measuring chamber. 3D measurements of slewing rings with a diameter up to 6,000 mm can be effected. This type of measurement is unique worldwide.

Classification

Many years of collaboration with certification and inspection authorities

The certification and classification by internationally recognised certification and inspection authorities serves as an external quality certification for Liebherr. Classifications and certifications of components and complete systems are common in the area of maritime applications and in the wind industry. Liebherr looks back here on the many years of successful collaboration with classification companies.

Classification companies

We work with the following certification and inspection authorities, among others:

Certificates in accordance with EN 10204

The European standard EN 10204 defines various types of inspection documents and test certificates. Depending on the requirement of the test and documentation scope, we may provide various certificates in accordance with EN 10204 for the raw parts. Certificates in accordance with EN 10204 include:

For typical applications in mechanical and plant engineering:

- Certificate of Compliance 2.1

- Factory Certificate 2.2

- Acceptance Certificate 3.1

For special requirements:

- Acceptance Certificate 3.2

The classification companies require certain certificates within the framework of a prescribed classification approval. Upon request, Liebherr issues and supplies the necessary documents.