Engineering partner for drive systems

Planetary gearboxes and rope winches from Liebherr are orientated around specific applications. Experienced designers work out the right gear solution for each requirement. During the design of drive systems, Liebherr employs state-of-the-art development and calculation methods. We continue to develop components and complete systems further.

High standards in design and manufacture

The integral construction method of Liebherr's gears allows for compact shapes and an optimum power to weight ratio. Well conceived design principles ensure an even load distribution of the individual stages and therefore a high power density.

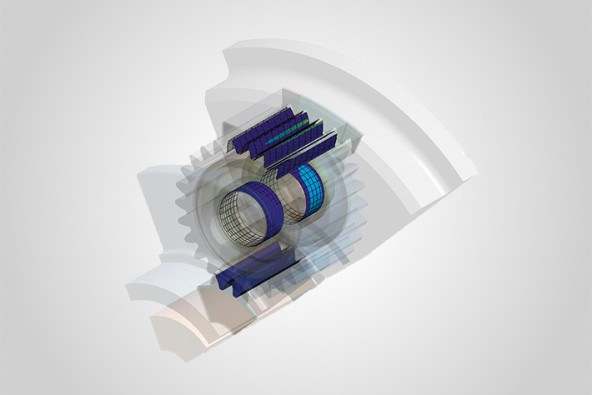

Using FEM, it is possible to determine the stress curve during meshing of planetary gears

Professional design

During the intricate design of Liebherr gearboxes, our experts rely on progressive simulation and calculation technologies such as the finite element method (FEM).

In the process, Liebherr acquires important knowledge on the load bearing behaviour or gearing safety. This results in constructive adjustments and contributes towards the ongoing optimisation of our products.

Liebherr rope winches with own planetary plug-in gearboxes during assembly

Unique vertical integration

Liebherr attaches great importance to high vertical integration while, at the same time, concentrating on the core processes. The resulting linked production and process competencies are the basis for high quality products.

Our production facilities, such as fully automatic gear production lines or state-of-the-art induction hardening machines are at the cutting edge of technology. They enable not only variable batch sizes but also guarantee consistently high quality.

Engineering competence for large diameter bearings

Liebherr works with renowned classification companies

Reliability on all levels

To assure the high standards, all company processes are orientated around quality in the area of gearboxes and rope winches.

Our drive systems comply with the specifications of various classification organisations such as Det Norske Veritas - Germanischer Lloyd (DNV GL), American Bureau of Shipping (ABS) or Lloyds Register of Shipping (LRS). Moreover, our certified suppliers are also required to comply with quality standards specified by Liebherr.

High quality materials

All torque-conveying gearbox components are made of top-quality case-hardened and tempered steels which are certified to the Liebherr works standard. This goes beyond the conventional industrial standards and includes a 3.2 material certificate in accordance with DIN EN10204.

Load test bench

State-of-the-art testing methods

Our calculation engineers rely on load bearing measurements performed using own high frequency pulsation and FZG stress test benches. In this way, we acquire precise configuration results. The calculated material curves are more precise than those from specialist literature and provide even greater accuracy.

Computer-supported documentation in BDE system

Consistent quality management

We document all production and assembly processes in a computer-supported production data acquisition system (BDE system). The central quality management system records all measures relating to production and assembly. This enables comprehensive control, monitoring and subsequent traceability.

Approved quality: certifications

The numerous certifications are testament to Liebherr's high standard of quality. Aside from the usual ISO standards of the quality management system, Liebherr has the following certifications:

- DIN EN ISO 9001:2015

This norm forms the basis for our QA system and the ongoing improvement process within the company Liebherr-Components Biberach GmbH for the business unit gearboxes and rope winches. - EN 1090-2:2008+A1:2011; EXC3 in accordance with EN 1090-2

This certification qualifies us to weld and produce steel support structures. These serve, for example, as earthquake protection in nuclear power stations. - DIN EN ISO 3834-2:2006

This norm defines the comprehensive quality standards for the fusion welding of metallic materials with regard to components of drive and control technology.