Click RELEASE VIDEO and follow the data protection notices.

At the peak of possibilities

The trolley is snowed in. In mid-September. High up on the Zugspitze, Germany’s highest mountain, this is not a rare event. Luis Schwatz dons his helmet, puts on his climbing harness and climbs the frosty ladder with a colleague until he reaches the boom, then continues for three or four more metres. It’s a first-class vantage point. He’s a dizzying 2,500 metres above sea level, with the shining turquoise Lake Eibsee lying at 973 metres above sea level. The Zugspitze is cloaked in cloud. The views are breathtaking, but it’s a vacuum, so he can devote his undivided attention to the trolley of the Liebherr tower crane. If it starts up with its weight on the hook - a prefabricated concrete part - chunks of snow and ice could fall onto the site below. To prevent this, Luis Schwatz is armed with a scraper and a few blows of a hammer. Now the trolley can work safely and freely.

The crane is perfect for us up here. Its handling is straightforward and it’s the ideal support for construction companies on mountains.

Not for the faint-hearted

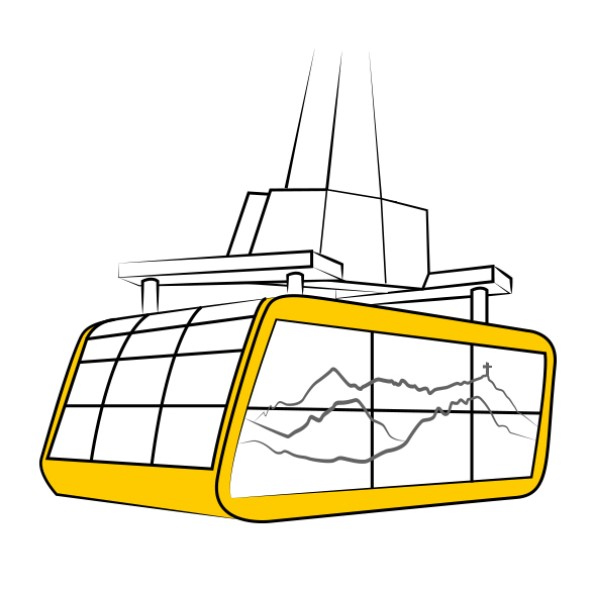

Luis Schwatz is a crane operator on Germany’s highest construction site. Those up here working on the new Eibsee cable car need to be weather-resistant, have a head for heights and not squeamish under any circumstances. It’s the only way to keep the machinery and materials in good condition at almost 3,000 metres above sea level. When Schwatz isn’t clambering around on the 50-metre-long boom, he is operating the Liebherr 150 EC-B 6 Litronic flat-top crane via wearable remote control. “The crane transports materials to the different areas of the site or removes construction waste. This is best done from the site below, where we have a better overview of the different site areas than we would from the cockpit”, says Schwatz. And then there are the visitors that flock to Germany’s top tourist attraction every day, who can also watch the ongoing site work. “We have been working up here for three years”, says Schwatz. “Always with an audience”, he adds with a smile. “Our site has almost become as big an attraction as the mountain itself”. And with good reason. Up on the Zugspitze, technological history is being made.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

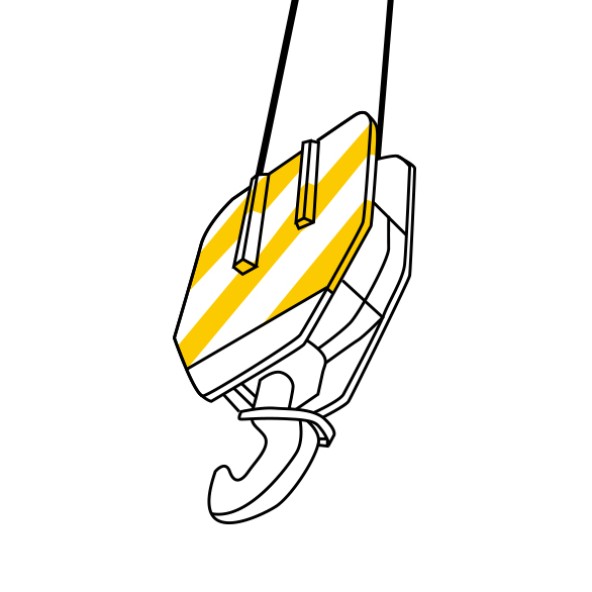

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Really strong: With extreme conditions athigh-altitude, the crane, with parts weighing many tonnes, is assembled by helicopter with millimetre precision.

Building a cable car: it’s an adventure

The old Eibsee cable car was decommissioned in April, making way for the new system. The good old rack railway is currently the only way to climb from the valley station towards the summit of the Zugspitzgipfel, taking around 45 minutes. On board is Martin Hurm. He is the manager of the cable cars and lifts on the Zugspitze and is responsible for the construction of the €50 million new cable car construction project in his capacity as project manager for the Bavarian Zugspitze Railway (Bayerischen Zugspitzbahn). Everything is coming together for the Deggendorf native. “If I had foreseen how much work it entails...”, he says, laughing.

The 49-year-old clearly delights in being part of making technological history in this unique location. And he’s in good company. The tourist development, new construction and extensions have been long-running projects for train operators on the Zugspitze since the early 1930s. The Eibsee cable car was built in 1963 to extend and alleviate the rack railway. It was a success at the time. Perhaps too much of a success, as it reached the limit of its capacity in the late 1960s when the great ski boom was gathering momentum.

A high-altitude construction site is an adventure in many ways. Technological, engineering, logistics, height and weather conditions.

Many virtues required

Ever since, maintenance and modernisation have been long-term plans on the Zugspitze. The thing is, they’re not all that easy to implement up on the mountain. “An alpine construction site is an adventure in many respects”, says Hurm. “Technologically, on an engineering level, logistically, and when it comes to heights and weather conditions. And, last but not least, it’s a constant challenge in terms of patience and persistence”.

The ‘reward’ for Hurm and his team is not only the most spectacular view of the site, but also the end result: a superlative cable car, the like of which has never been seen and which is set to break three world records: the highest steel cable car prop (127 m), the largest total elevation gain (1,945 m between the valley and upper stations), and the longest free span (3,213 m). Its previous capacity of 260 will be increased to 580 mountain enthusiasts per hour.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).On the top: At an altitude of almost 3,000 meters, the Liebherr flat-top crane becomes an attraction - not only for construction workers but also for tourists on the peak of the Zugspitze.

“No room for planning mistakes”

On a construction site at almost 3,000 metres above sea level, everything has to be perfect. This is ensured by the experts at Liebherr Tower Crane Solutions - a department specialising in planning and implementing very specific applications. Here, project manager Michael Weißschädel tells us how Liebherr’s crane technology is being used at the Zugspitze’s summit.

Mr Weißschädel, challenging construction sites are nothing new for Liebherr’s tower crane solutions. What makes a building site on Germany’s highest peak so unique and challenging?

Michael Weißschädel: The mountain location, the strong winds, the temperatures and the snow and ice make it different to a ‘normal’ site. Every detail must be thought through to be able to safely assemble this special crane on the Zugspitze, operate it safely and dismantle it safely, too. And the view from the highest point in Germany is something truly special for the fitters, service technicians and crane operators.

Which mountain ‘configurations’ were required for the crane?

Liebherr cranes are generally operational at temperatures down to -25°C. The 150 EC-B 6 Litronic also has a particularly strong tower combination, which can even withstand extreme wind speeds of up to 280 km/h.

Which skills do Liebherr team members bring to assembling and maintaining the crane up there?

Our trained fitters and service technicians are no strangers to working at heights - otherwise, they would be in the wrong job. The crane itself is not built at a particularly great height, but there is a drop of a few hundred metres right next to it. It’s impressive, but it’s ultimately not that different to working with a suitable crane on a high-rise building.

What has particularly interested you about this project?

The new Zugspitze cable car is a unique site in a unique location. From a technical perspective, the planning and assembly via helicopter at nearly 3,000 metres above sea level expertly done by all involved. As a result, every little detail had to be considered beforehand. Once the parts are up on the mountain or being lifted by the helicopter, everything has to be perfect - there’s no room for mistakes. The team did a perfect job.

Sky high: the Liebherr flat-top crane 150 EC-B 6 on the Zugspitze

- Erected at 2,950 metres above sea level

- With its boom, it overhangs the 2,962-metre-high summit cross by 13 metres

- This makes the crane the highest point in Germany for the construction period and a few months afterwards

- The jib radius is 50 metres at a hook height of 18.6 metres

- Its modular design means that it can be easily dismantled into individual parts with a maximum weight of 3.4 tonnes

- The crane modules correspond to the maximum load capacity of the helicopter required to transport them from Sonnalpin to be assembled at the summit

The project at a glance

A herculean task, right to the end

The countdown is on – there are just a few weeks until the launch. The last of the four new suspension cables for both cabins at the mountain station was moved into place and secured in mid-October. It was a herculean task. Each of the 4,900-metre-long suspension cables weighs 153 tonnes. The suspension cables on the old cable car managed 200 metres per hour on their way to the top. That was with both cables weighing 30 and 39 tonnes - light as a feather by comparison.

Pretty extreme - working on the mountain

Everything is extreme - even the manager’s composure

Around 100 people are currently working on the site. The wind is whistling around up at the summit cross. Ice crystals dance around the steel frame and cables. The -2°C on the thermometer feels much colder. Everything up here, it seems, is extreme. Even the composure of Martin Hurm: “You can’t fight the weather up here”, he explains. “But you can make the best of it”.

The two cable car cabins with floor-to-ceiling glass have already arrived, says Hurm. They’re wrapped up at the valley station waiting to be assembled. “They will be put into operation on 21st December”. There’s no doubt in his mind. And the crane? “It will be staying put until the spring, when all of the work is completed”, explains Hurm. Its concrete foundation will be staying, however. “We know we might need the crane again at a later date”.