Thermal Management

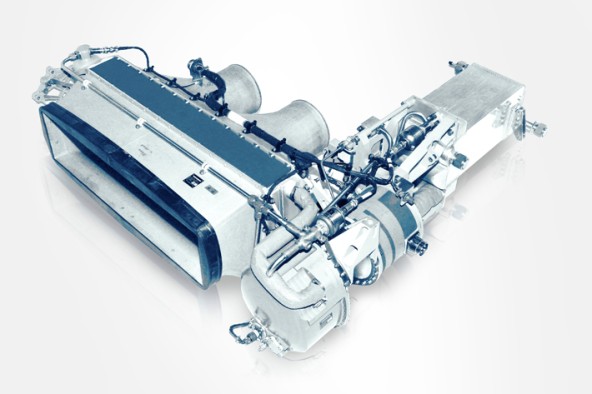

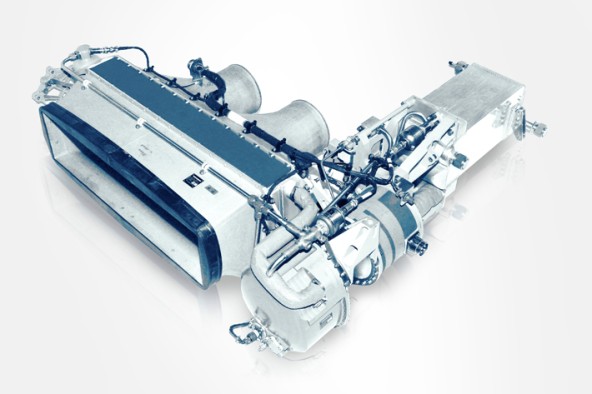

Supplemental cooling system for the Airbus A380

During decades, we have gathered expertise regarding materials as well as the design and manufacture of key components for thermal management systems such as compressors, turbines, heat exchangers.

We manage the complex technology in-house through a dedicated system engineering process and continuously increase the key components’ compactness and efficiency. Furthermore, our manufacturing capacities allow for a high volume production.

Our cooling systems are on board of commercial and military aircraft, as well as helicopters and satellites.

The supplemental cooling system developed and manufactured by Liebherr-Aerospace for the A380 is used for the cooling of food and beverages on board.

For food storage on board some long-range aircraft types, a high power centralized cooling system is necessary. A liquid loop carries and distributes the generated cooling in every place where it is required. A heat exchanger connected to this liquid loop converts the cooling power into air-cooling blown on the food.

Our avionics thermal management systems can also cool down aircraft radars or electronics.

We also supply hydraulic cooling systems to cool down high-pressure (5,000 psi) hydraulic channels onboard the aircraft.

Liebherr is providing evaporators and condensers for Mechanically Pumped Loop (MPL) cooling system for satellites. These are key components of the next-generation satellite’s payload and platform cooling system, which actively manages the electronic heat dissipation.

As part of an innovative MPL, the evaporators and condensers will be in space for at least 15 years without maintenance. This means that the evaporators and condensers have to be completely free from leakage as well as extremely reliable and robust to operate flawlessly during this period at high heat exchange performances.

Component of an oil cooling system

Due to the criticality for the operation of a helicopter, helicopter transmission systems are typically lubricated and cooled with their own oil supply. That is where we step in with our advanced cooling systems comprising heat exchangers, valves, filters and fans to manage the gearbox oil temperature in every situation of the flight.

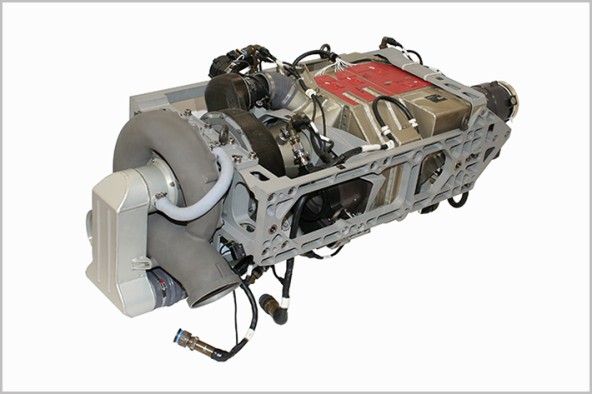

Environmental control unit for POD

External PODs are carried on many types of tactical, transport, and special mission aircraft to provide extended capability for specific missions. Such PODs contain a range of sensor systems that are extremely sensitive regarding temperature. Liebherr POD cooling systems guarantee a reliable temperature control by using vapor cycle or air cycle technology for various cooling power needs. Based on our innovative engineering solutions, our POD cooling systems comply with key operational requirements, as weight, reliability and maintainability.

The innovative liquid skin heat exchanger was tested on board DLR’s A320 in 2014.

Engineers of Liebherr-Aerospace, Airbus and the National Aeronautics and Space Research Center of the Federal Republic of Germany (DLR) have cooperated in the European research program "Clean Sky" to find solutions to counteract the significantly increasing thermal loads and heat density in aircraft

The idea: Dissipate the heat through a so-called liquid skin heat exchanger developed by Liebherr-Aerospace with the help of liquid coolants.

Our specialists for air management systems have designed a test bench of a liquid loop system to simulate thermal loads in the aircraft and to feed the liquid skin heat exchanger with coolant. Both, the liquid skin heat exchanger and the liquid loop system operate completely independent of other systems in the aircraft. For a practical test, both elements were integrated into an Airbus A320 test aircraft provided by DLR in 2014.

Liebherr-Aerospace is working to improve the production process in order to enable serial production of the heat exchanger, and to reduce the weight of the system using composite materials.