Liebherr-Aerospace in Saline

Heat Transfer Equipment Servicing is Thriving

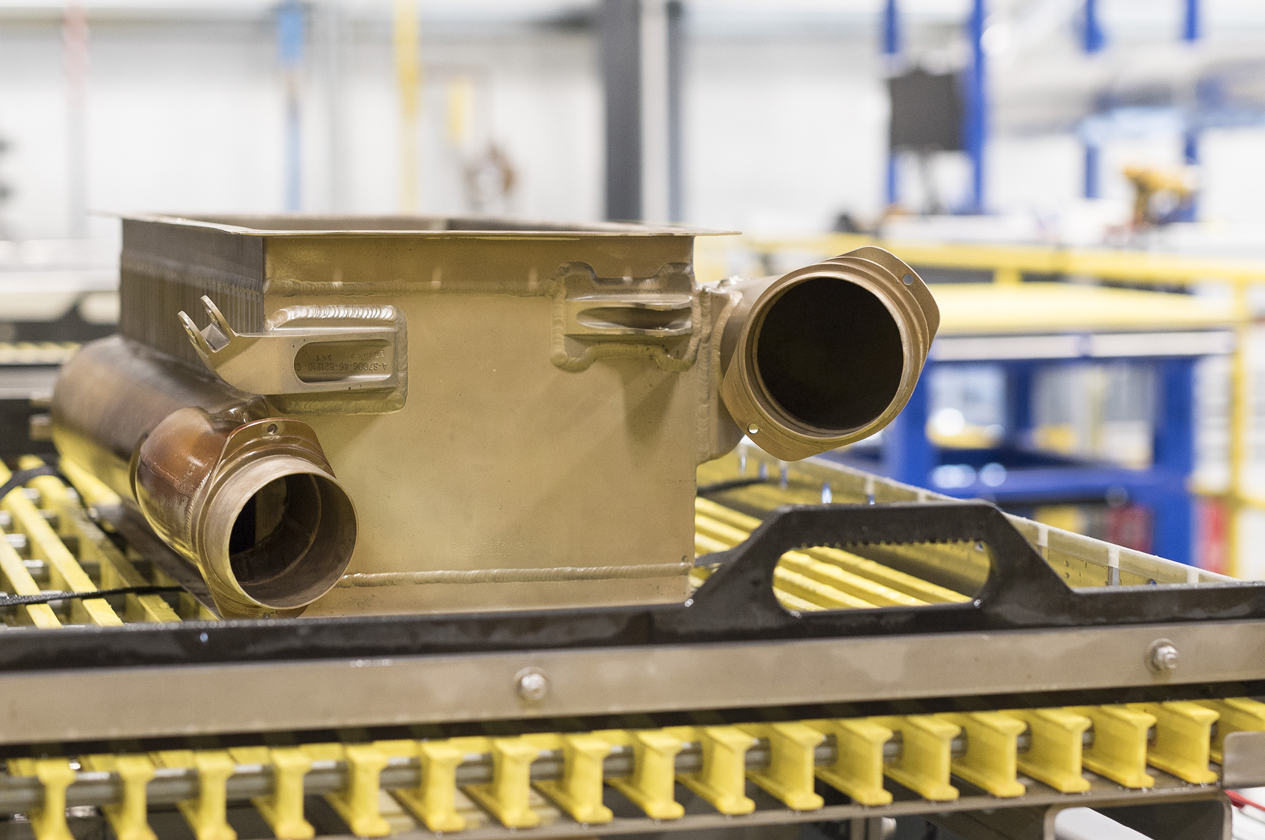

With its purpose-built facility in Saline, Michigan (USA) Liebherr-Aerospace has established capabilities to repair heat exchangers and other components of the environmental control system on board an aircraft. This increases the size of the service and support center by 40%. Liebherr uses state-of-the-art technologies for the repair process.

Video: Discover our state-of-the art facilities

- Advanced production technologies: non-contact metrology, robotic welding, 3D printing

- High-skilled dedicated staff

- Cost-effective quality product on time

- Environmentally-friendly processes

Incoming inspection

Our technicians assess the unit and the customer's requirements.

Built with the future in mind: our chemical processing platform

- 16 fully automated 600 gallon chemical and rinse tanks

- Built-in filtration

- Agitation and ORP adjustments

- Underwater proof pressure tests

"Our facility works per the OEM CMM and only uses original parts."

Dan Malone, Repair Technician Supervisor

We are able to produce the best finished products on the market.

- CMT robotic welding

- Non-contact dimensional verification

- High-skilled TIG welders

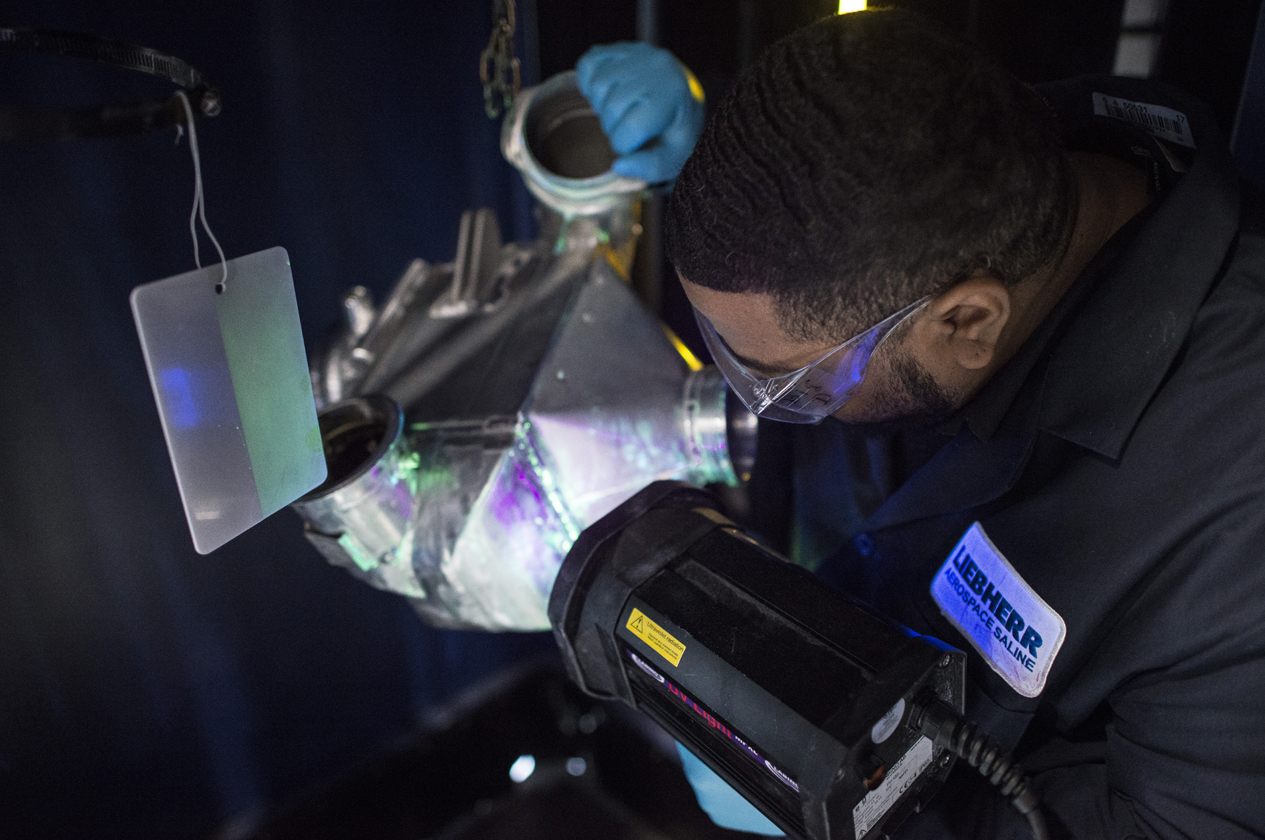

We comply with OEM quality requirements.

Every unit undergoes dye-penetrant inspection to verify the weld quality compliance with OEM criteria.

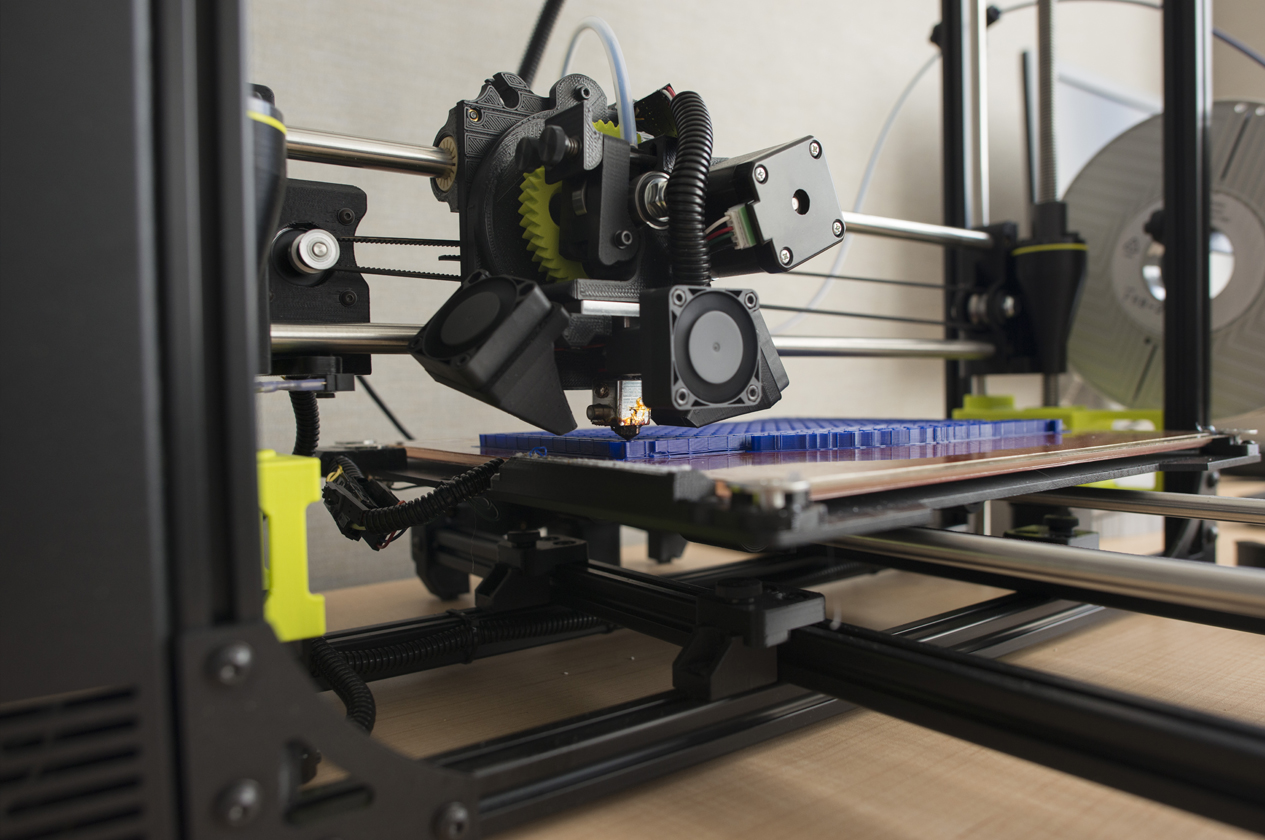

3D printing to speed up our capability development

Printing of V-band clamps for low pressure applications, cradles for parts during welding, adapters for internal varnish application and supports for testing instruments

Our units meet the highest standards.

Final test setup designed to accurately read flows and pressures of a unit, which ensures a long lasting, quality product.

Environmentally-friendly processes

Our waste water treatment plant enables us to remove heavy metals and chemicals from our waste stream.

"Our facility employs skilled people, using the latest technologies to ensure a cost-effective, quality product gets to our customer on time."

Brian Publiski, Heat Exchanger Repair Shop Manager