6 minutes - magazine 01 | 2024

Wear-free

TraXon DynamicPerform proven in practice. Customer experience with the new TraXon DynamicPerform gearbox.

Wear-free

TraXon DynamicPerform proven in practice. Customer experience with the new TraXon DynamicPerform gearbox.

Wear-free starting and centimetre-precise manoeuvring without overheating – this is exactly what TraXon DynamicPerform offers. Over the past few months, we have successively introduced this new transmission – more precisely, the new, oil-cooled clutch module of the TraXon transmission from ZF – into our current range of 5-axle vehicles as well as most of our 4-axle machines. We are currently in the process of installing it in our 3-axle LTM cranes.

Tight construction sites require manoeuvring with centimetre precision.

We are naturally interested in how the new transmission is being received in practice. So we asked our customers. Hubert Maltan, who owns the family business Maltan Fuhr- und Entsorgungs GmbH in Schönau am Königsee together with his brother Josef, is primarily responsible for technical matters and occasionally sits behind the wheel of one of his six mobile cranes himself.

The latest addition to the fleet is the LTM 1150-5.3 with the new clutch module. “In our mountainous region in the Berchtesgadener Land, the oil-cooled clutch is a big step forward. We can now also manoeuvre easily on inclines without having to worry about the clutch overheating. There’s a lot of load on the clutch.” Hubert Maltan’s assessment of the TraXon transmission is generally very positive: “It has many gears and is finely tuned. But with the previous dry clutch, drivers had to be careful when manoeuvring. It’s much more comfortable now.”

Ueli Neuenschwander had the same experience. He’s a crane driver at the Härkingen branch of the Swiss crane and logistics company Emil Eger AG: “Just today, I had to manoeuvre in the snow with my new LTM 1230-5.1 and I have to say the new transmission really is better than the old one. Especially in situations like this, you had to be careful that it doesn’t get too hot. The new crane is also much smoother when starting off on steep terrain, almost like a torque converter gearbox.”

Ueli knows what he’s talking about, having also driven an LTM 1300-6.2 in the past. This crane type, like all Liebherr mobile cranes with 6 axles or more, is equipped with the ZF TraXon Torque transmission with torque converter coupling. Even though very high input torques are involved, starting and manoeuvring is comfortable with no shuddering and also zero wear thanks to the hydrodynamic torque converter.

We are naturally delighted with this positive feedback. Our close collaboration with ZF and intensive testing of the new transmission variant have paid off. What experiences have you had with the new oil-cooled clutch? We look forward to hearing from you, too. Write to [email protected].

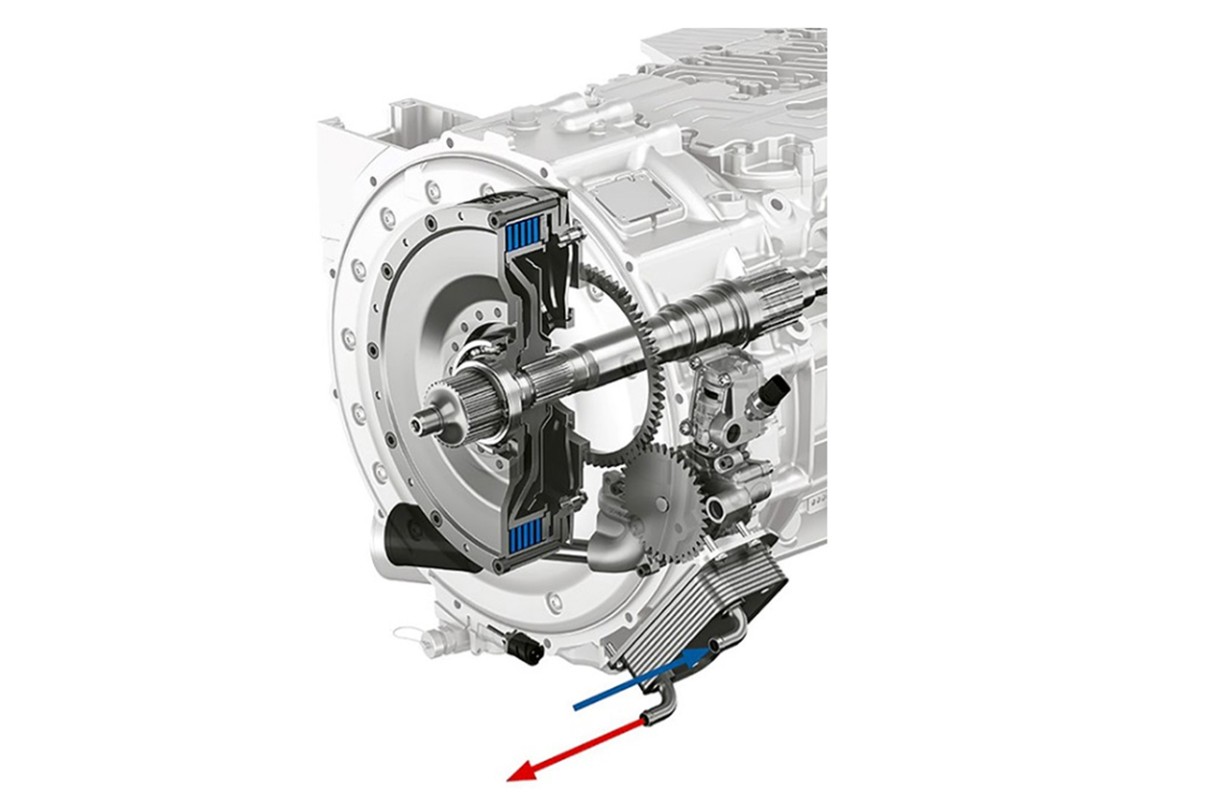

ZF TraXon DynamicPerform gear unit

?? hot oil (from coupling) ?? cold oil (to coupling)

The innovative DynamicPerform clutch module delivers almost zero wear starting and manoeuvring for the modular ZF TraXon gearbox without overheating. It transfers the engine power using an oil-cooled multi-disc package which is immersed in oil. The friction heat generated when starting is dissipated in the clutch oil and supplied to the vehicle’s cooling system via an oil/water heat exchanger. Permanent, almost zero wear manoeuvring is made possible as a result of the high energy and power density using a calculation model. A coupling protection function also prevents the clutch from overheating in extreme load cases, thus preventing the associated wear and potentially the premature destruction of the clutch. This prevents downtimes and helps to significantly extend the service life of the drivetrain. Crane operators thus benefit from greater efficiency and lower maintenance costs. Drivers are assisted by the easily adjustable clutch.

This article was published in the UpLoad magazine 01 | 2024.