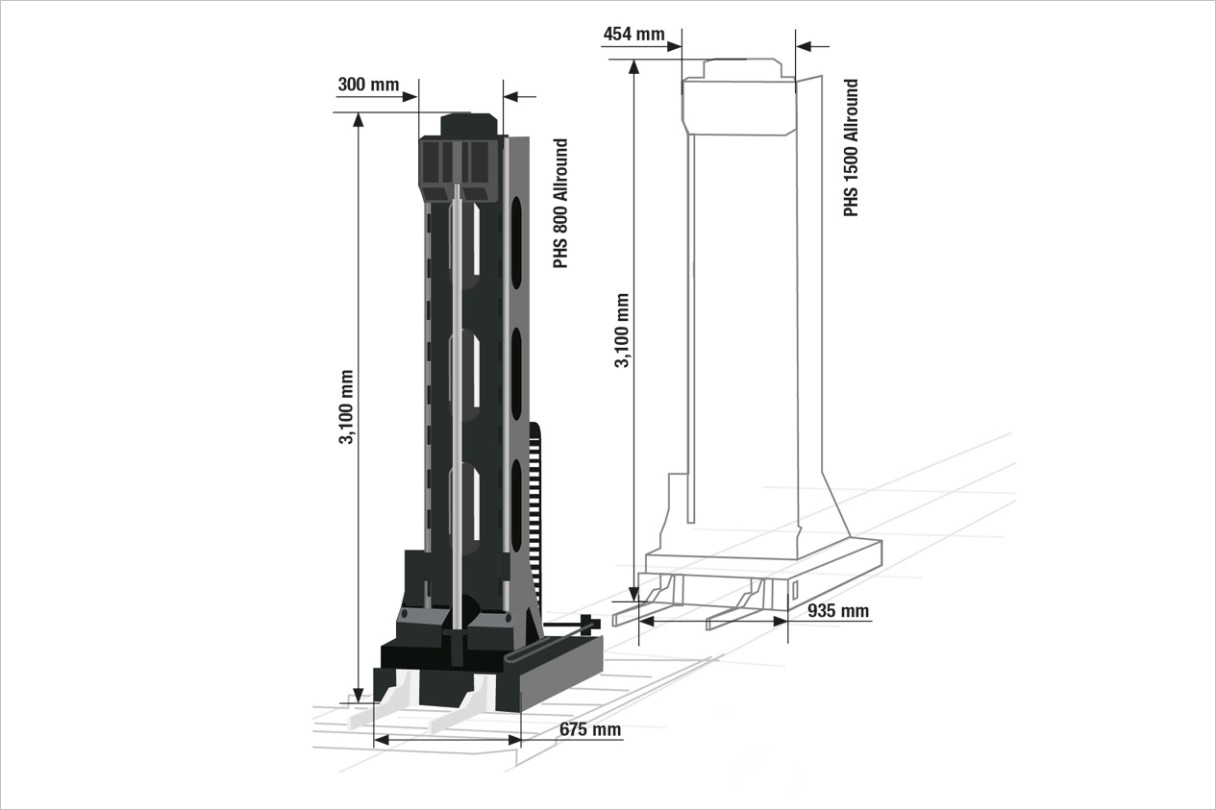

PHS 800 Allround – the slim alternative

Liebherr presents the latest member in the PHS Allround family, the PHS 800 Allround. It has a narrower design than the PHS 1500 Allround, which makes it ideal for automated loading of smaller machine tools while retaining the basic principle of modular design and universal applicability and expandability.

Flexible, modular and uniquely adaptable to the needs of automation customers, the PHS Allround pallet handling system has become Liebherr’s best-selling automation system. Now, the family of Allround systems is being expanded: The PHS 800 Allround is narrower and lighter than its “big sister”, the 1,500 kg version. It can handle transport loads of up to 800 kilograms and although it has the same height, it has a narrower lift module and a narrower telescopic fork for smaller pallets. This means that machines with a small machining chamber can now be loaded automatically.

Tried-and-tested components

The successful Allround system concept has been retained in this smaller version. The possibility of arranging machines, additional devices and shelves at the front ensures high flexibility in the system design. The unique design principle with a detachable front access allows individual machines to be disconnected from the system, while the remaining machines continue to produce without restriction in automatic mode. Two control variants for the master computer (Soflex and Procam) can be exclusively configured to the requirements at hand. Many components of the PHS 1500 Allround are also installed in the smaller version: proven high-quality components such as the floor track, sprocket, mount, C-axis and rotary axis have been retained.

The narrower lift module enables the PHS 800 to load machines with small work areas

Highlights at a glance

- Modular system

- Flexible layout

- Front access

- Optional: double loader

- User-friendly control system

- NEW: narrow lift module with narrow telescopic fork (for PHS 800)

Effective automation from batch size 1

The expanded PHS Allround system not only offers intelligent parts handling, but also maximum flexibility with regard to batch sizes; automation can be effective and economical even from batch size 1. For complex workpieces with high component variance, the PHS system acts as a workpiece storage unit and performs organizational tasks. This means that spindle running times can be increased to more than 90 percent and expensive setup times can be significantly reduced, freeing up operators for value-adding tasks.