Sturdy absorbers by Liebherr

Shock absorbers capable of withstanding high loads have a long tradition at Liebherr. External customers, too, rely on the low-maintenance damping systems. We optimise these for application-specific use in mobile and stationary areas.

Liebherr shock absorbers on a mining truck

Low-maintenance suspensions for mining applications

Our mining suspensions are one example of use: Thanks to their compact dimensions and the use of an oil/gas mixture, we can dispense e.g. with an additional piston accumulator system. Furthermore, HVOF piston rod coatings give suspensions very low maintenance properties and ensure that they can be used even in extreme situations. The use of biologically degradable oils also means that Liebherr suspensions do not burden the environment.

Product portfolio

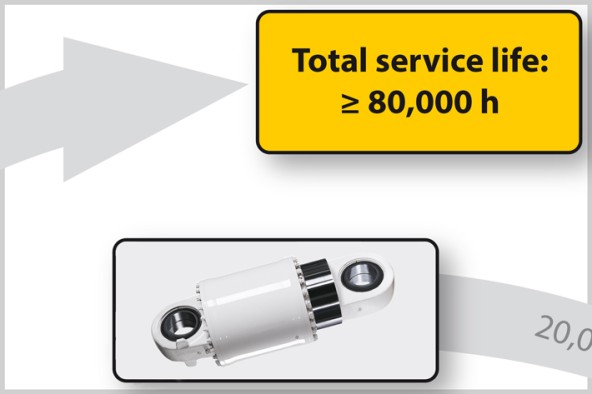

Longer service life for shock absorbers

Longer service life thanks to lifecycle management

Efficient remanufacturing means that the service life of mining suspensions can be extended up to 80,000 operating hours. Within the scope of the worldwide Reman programme, Liebherr targets individual components for reconditioning. In this way, Liebherr allows the suspensions to be used up to three times.

Vibration protection with viscosity absorbers

For effective control of vibrations, Liebherr produces high performing viscosity absorbers. These protect buildings that are at risk of earthquakes, for example. Our viscosity absorbers prove themselves anywhere that requires a reduction in oscillations.