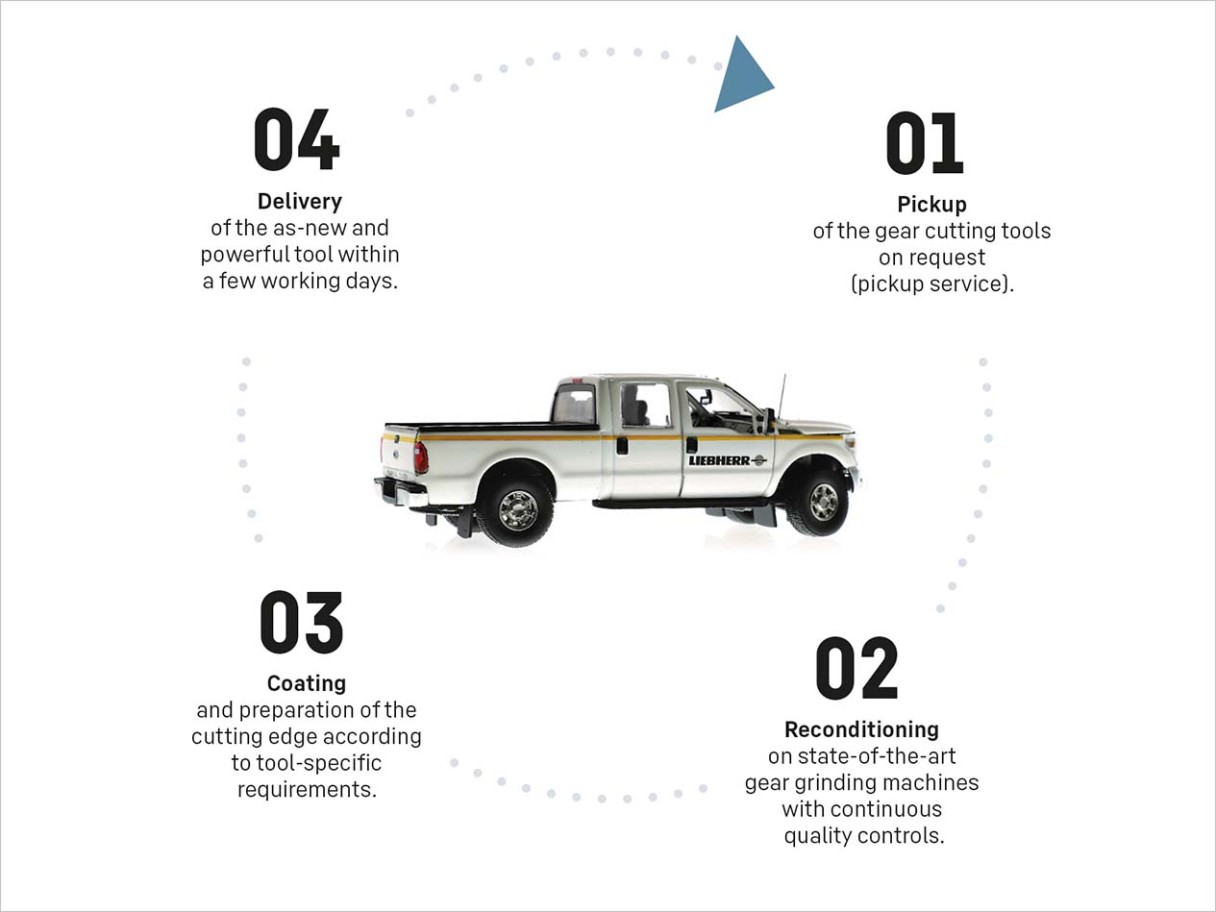

Gear cutting tools such as hobs, ChamferCut, shaper cutters, skiving wheels and CBN tools for hard-fine machining are usually repaired and reused multiple times. Liebherr offers a service for sharpening and resurfacing these tools, which restores the worn tool to its original condition. In addition to the quality of the tools, short turn-around times are important, because this way, companies can keep their tool inventory and the associated costs to a minimum.

Free pickup service

Liebherr also now offers a free pickup and delivery service from its Ettlingen site. “Our pickup service makes things easier for our customers by reducing their handling and administrative tasks,” explains Haider Arroum, Head of Sales for Gear Cutting Tools in Ettlingen. The Liebherr van makes regular trips to companies that frequently have their tools reconditioned – several times a week if necessary. “Often, the tools are ready for picking up by the time our driver arrives – which is a great sign of trust for us,” says Arroum.

Quality and short turnaround times

Liebherr not only reconditions its own tools, but also those of other manufacturers. Thorough tests and checks ensure the quality of the tools. From pickup to delivery, reconditioning takes a maximum of two weeks. Alongside this, Liebherr offers expertise and advice. “Customers know they can rely on us,” says Arroum. In addition to the Ettlingen site, Liebherr’s service partners in the United States also offer pickup service, and it is also planned for the Turin site.