In order to accommodate the largest dimensions, the Liebherr portfolio also includes segmented large slewing bearings alongside its one-piece slewing bearings. Starting from a diameter of around 9.5 meters, the bearings can be produced in this segmented format.

The large slewing bearings, tailored individually to match the customer project, can be used for rotating thousands of tonnes of steel, and are characterised by their low torque and high load carrying capacity. In this way, Liebherr is able to support the ongoing development of offshore machine construction, and the ever-larger dimensions at play in this sector.

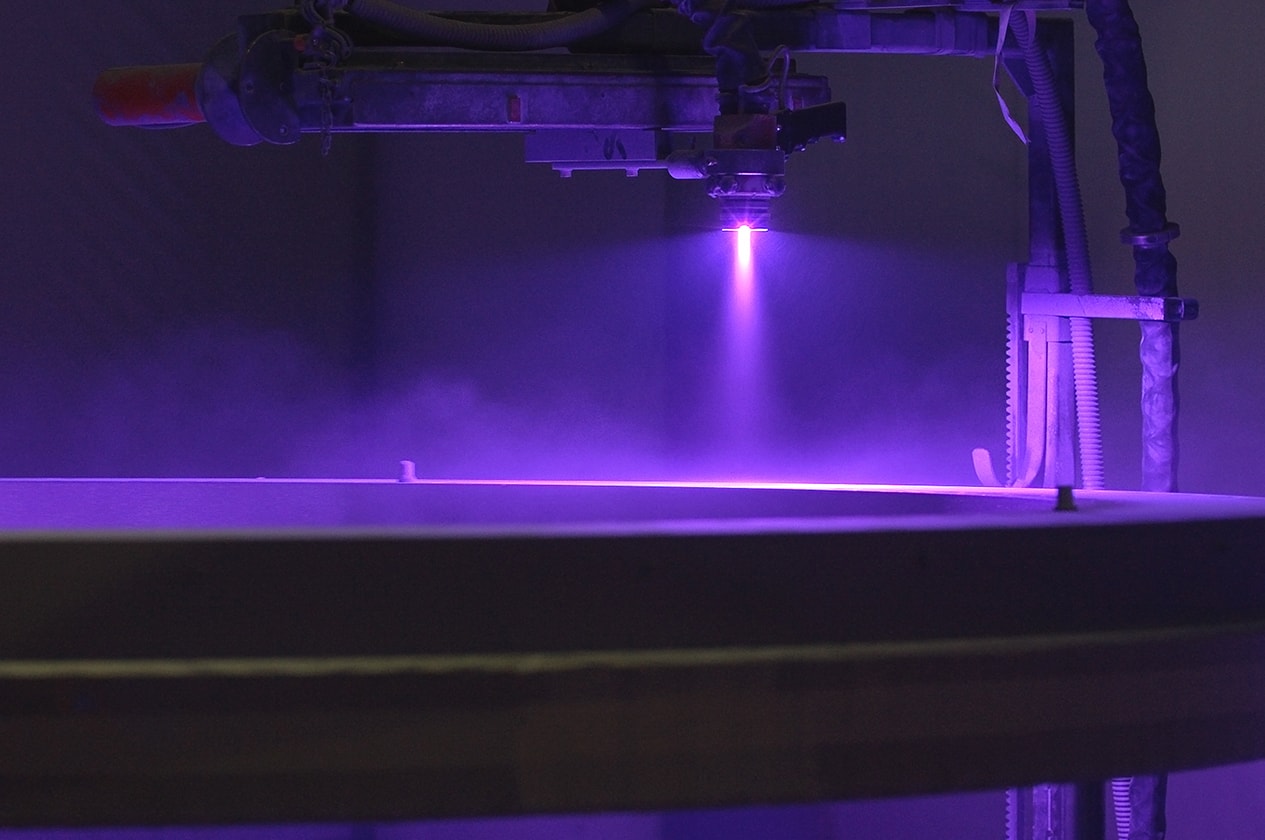

The surfaces of the bearings can also be protected with a corrosion-proof coating in the case of segmented bearings, too. For this, various technologies are deployed in line with DIN EN ISO 12944 and DIN EN ISO 2063.

With its state-of-the-art systems technology in the coating of parts, Liebherr sets new standards in surface protection. Liebherr supplies bearings in all corrosion protection categories, from C1 to C5M. The implementation and nature of the surface protection is adapted according to need and purpose of use.

Liebherr can count on its own in-house manufacturing skills for the production of the bearing raceways. The raceway contours are shaped using CNC turning and milling machines. For segmented bearings, the bearing raceways are then induction-hardened in their segments. Specific induction hardening machines guarantee the highest quality. Alternatively, through-hardened insertion plates can be used as raceways. In both cases, the hardening extends the service life of the bearing and reduces wear and tear during operation.

On account of the individual configuration of the large bearings by our engineers, direct cost advantages are generated for our customers. Based on FE simulations, the components are also optimally tailored to suit the adjacent construction.

The segmented design not only makes transportation easier, but also significantly facilitates the handling of the large slewing bearings. For on-site assembly of the components, our service team is available to provide advice and assistance.

As well as the corresponding specialist skills, we can make available to you, for preassembly, a mobile assembly table including drive. This consists of individual, interlinked blocks, and can in this way be individually adapted to the diameter of the slewing bearing.

The world's biggest cranes are used in the offshore sector. Slewing bearings that are used in this environment need to fulfil particular requirements, and not just in relation to their dimensions. Stability and reliability are indispensable in the harsh conditions of offshore use.

Liebherr works with all the common classification companies to obtain the usual certifications in this sector. These certifications guarantee that our slewing bearings fulfil the highest quality requirements.

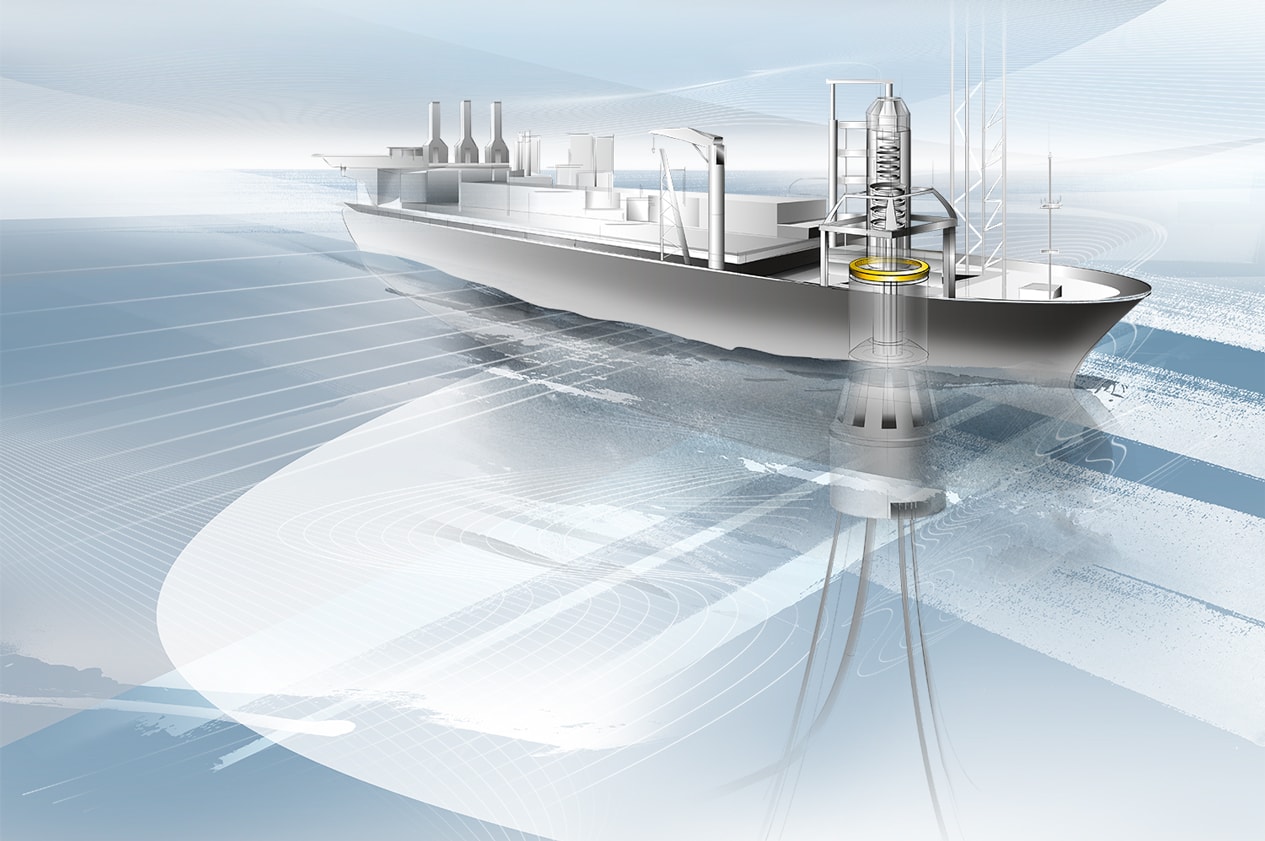

Floating Production Storage and Offloading Units (FPSO) are oil tankers that are used for the production, storage, cleaning and offloading of extracted crude oil or natural gas. These are secured to the deep sea floor by means of slewing anchors. Segmented slewing bearings incorporated in these anchors ensure that the ships can freely rotate around the oil pipelines.

When designing its bearings, Liebherr always focuses squarely on the application requirements. Since offshore anchoring systems are extremely demanding in terms of load transfer and sealing, we optimise the bearings used in this environment according to these criteria.

Then get in touch:

- Tel. +41 56 296 43 00

- E-Mail [email protected]