Aerospace and transportation systems

Aerospace and transportation systemsThe product was added to your wish list.

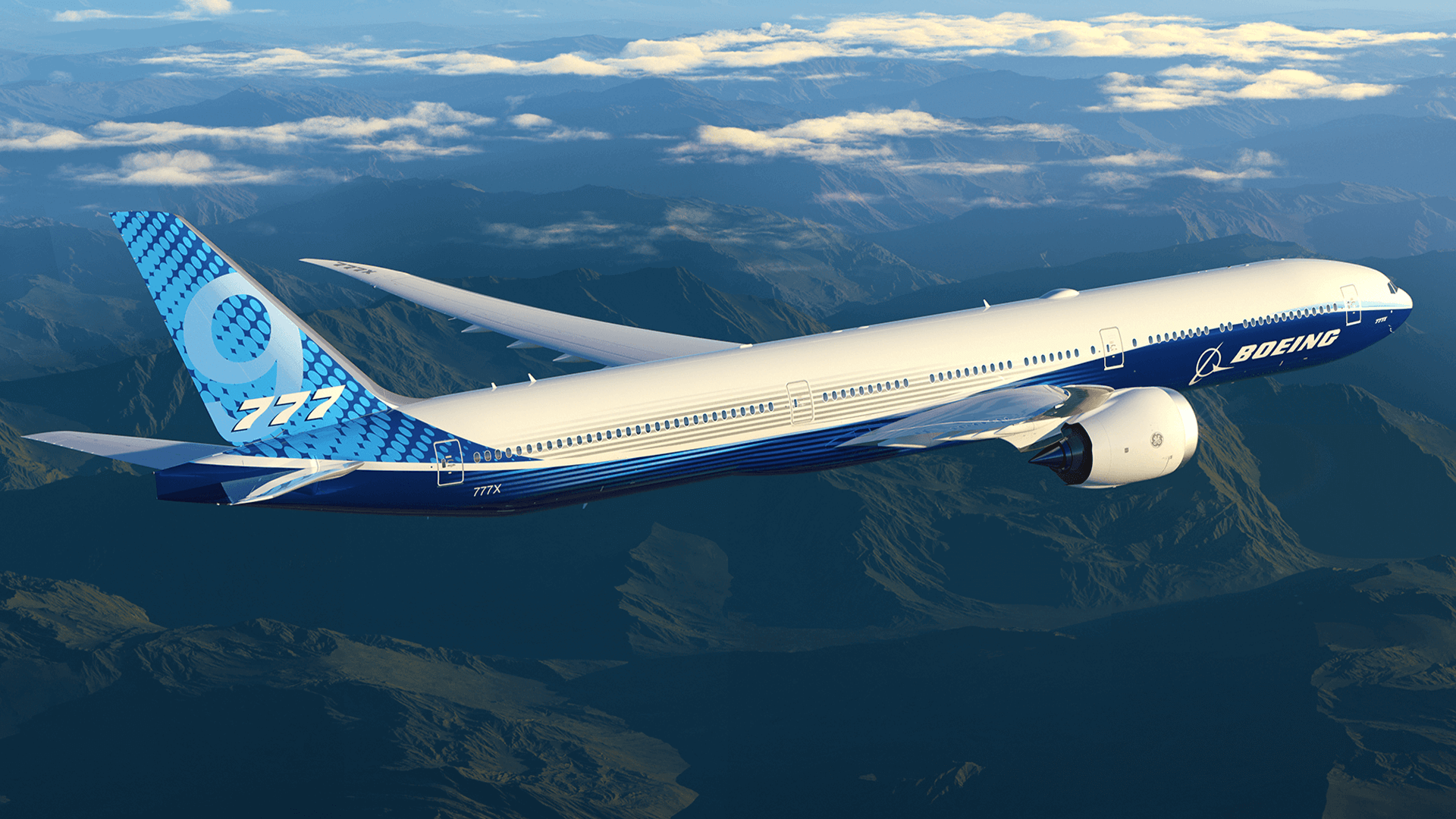

777X

Liebherr has been selected to manufacture major components of the high-lift system, as well as the folding wing tip system for the 777X, Boeing's latest widebody aircraft program built on the basis of the market-leading Boeing 777.