Liebherr segment clamping arbor SECLA

The clamping fixture for optimum quality and very fast delivery times

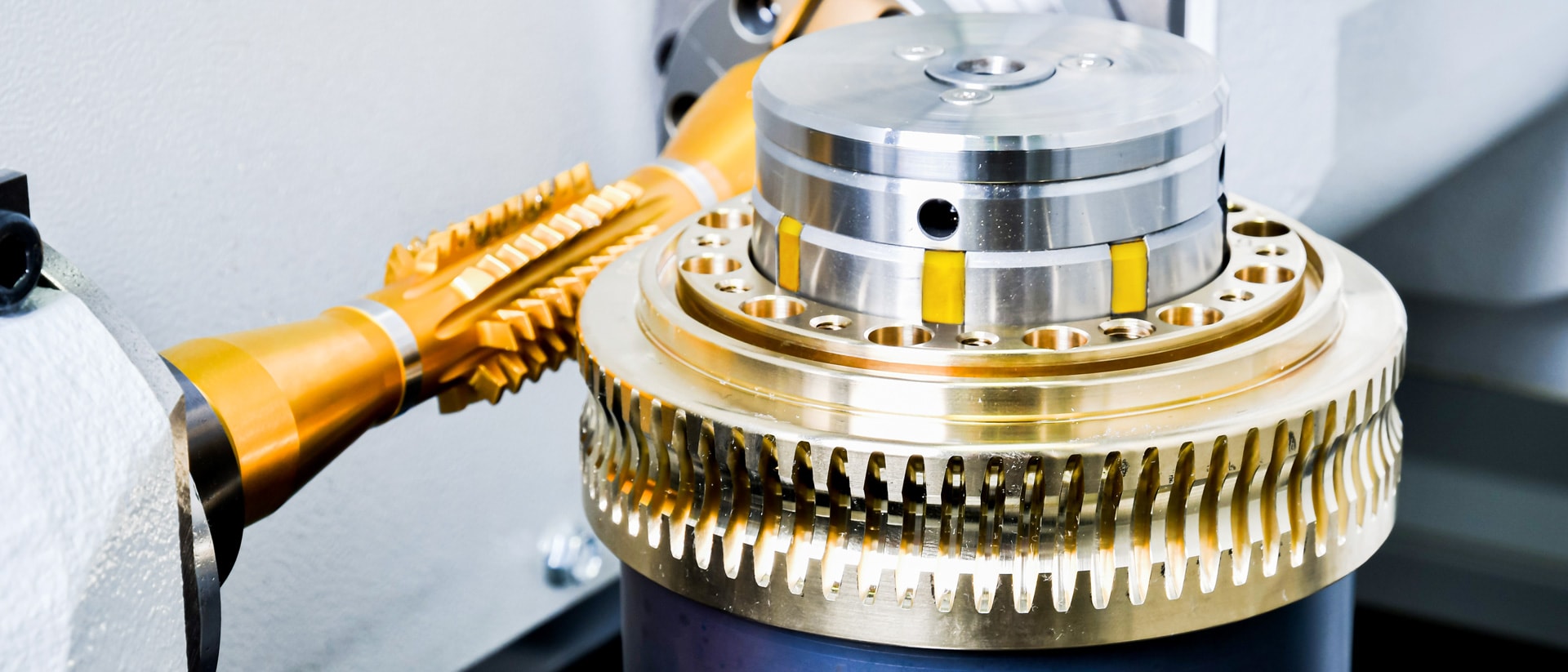

Clamping systems for gear manufacturing are usually very individual and have special requirements regarding concentricity and interfering contours. For this reason, it is particularly important to find the right clamping device for the application.

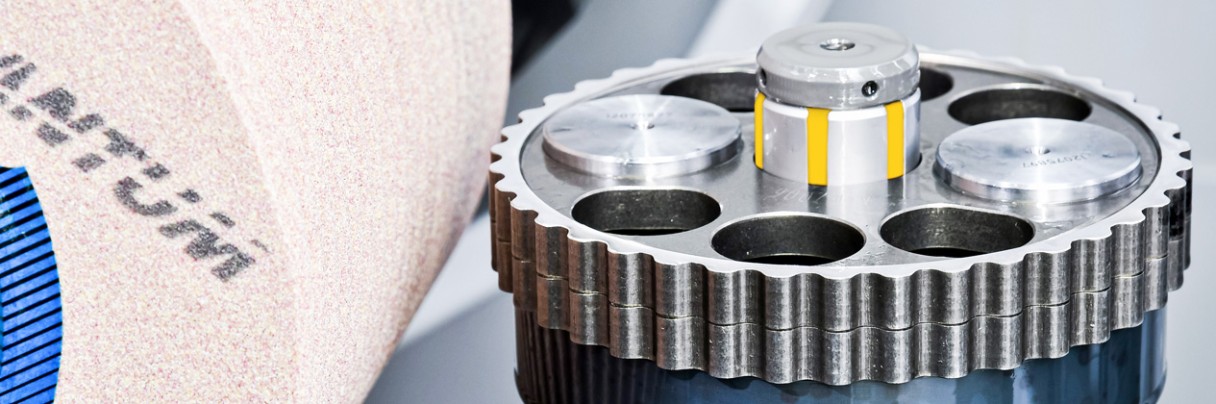

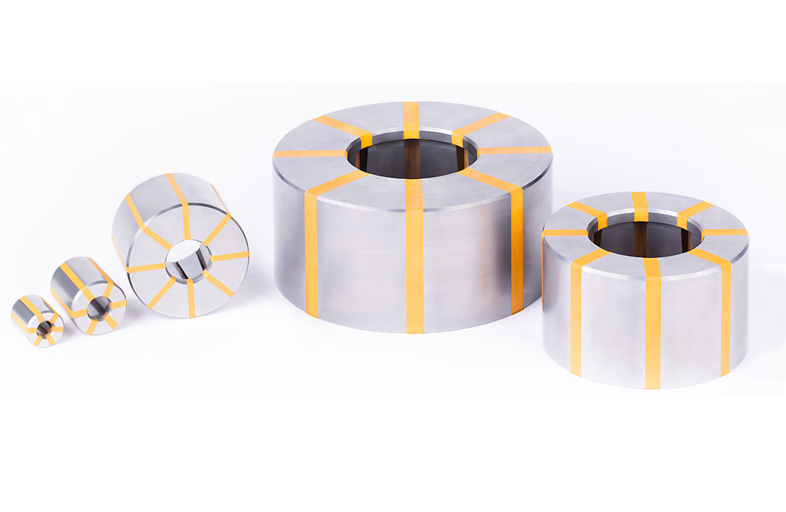

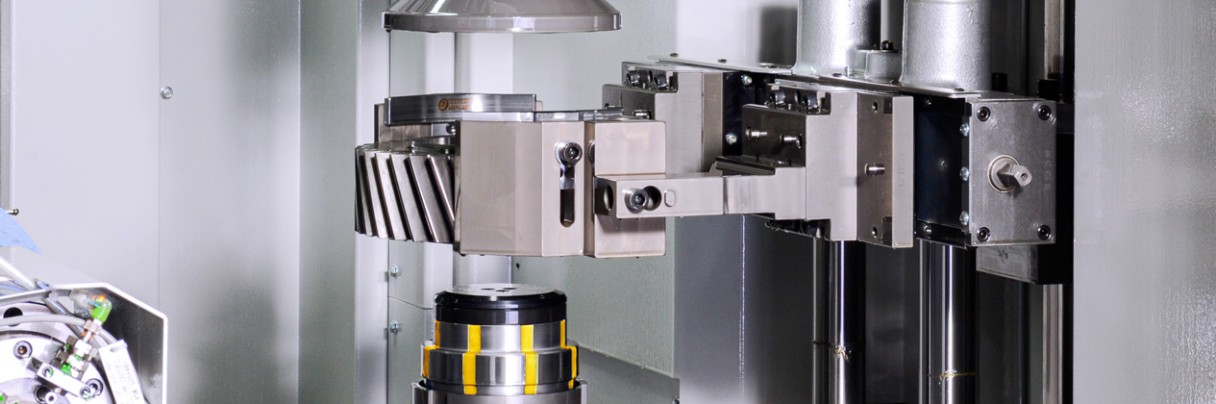

Liebherr’s segment clamping arbor SECLA is an innovative, inexpensive standard solution which will be delivered to you within just ten weeks. The clamping technology reduces expensive downtimes and is suitable for all Liebherr technologies (gear hobbing, shaping, skiving, grinding).

01/02

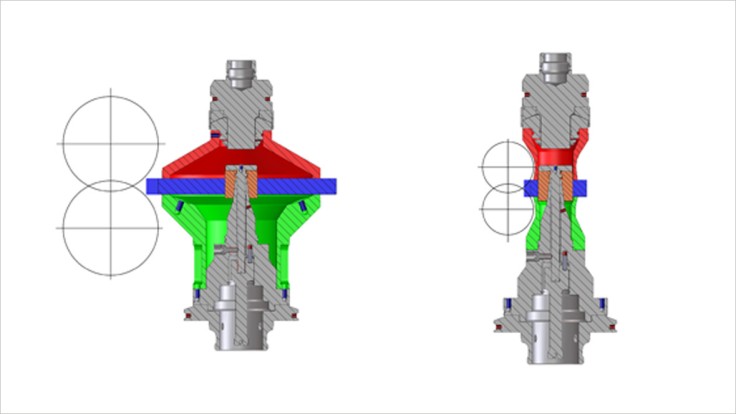

Video: The operating principle of our segment clamping arbor explained

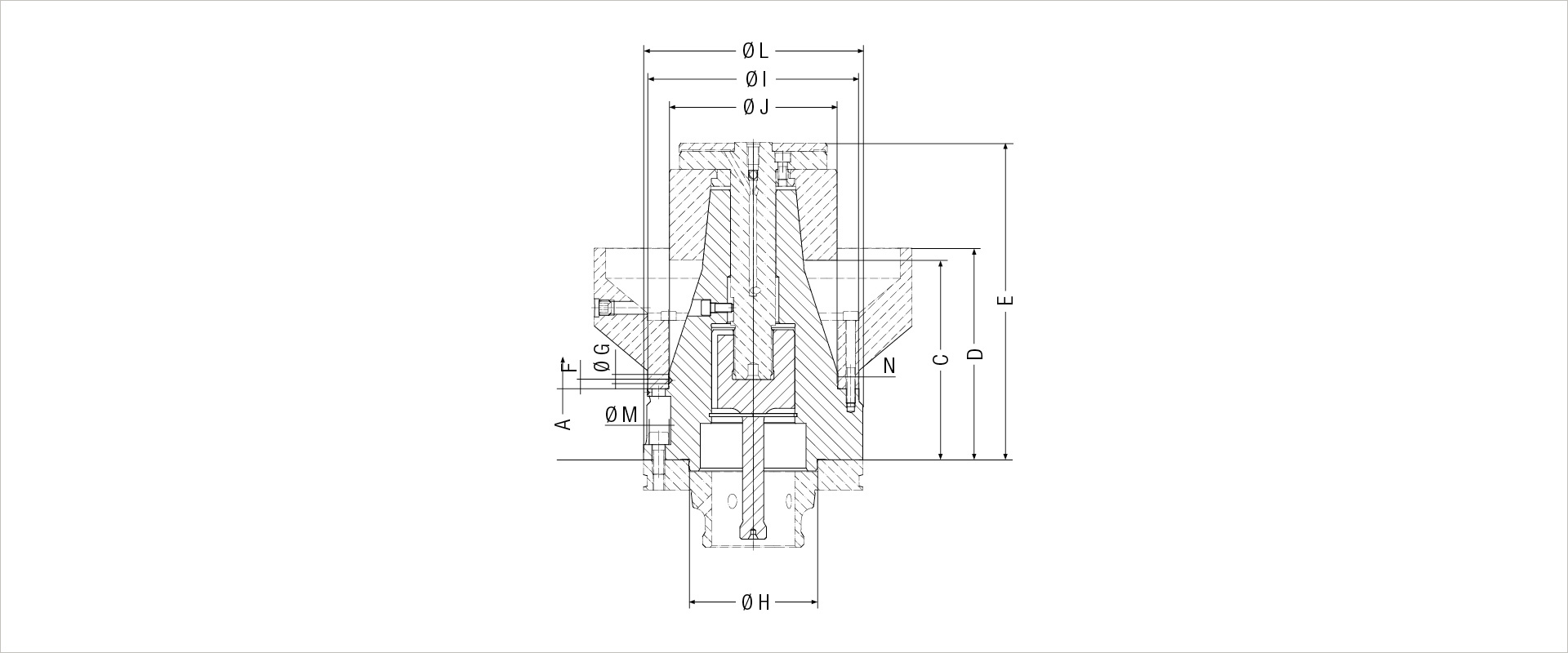

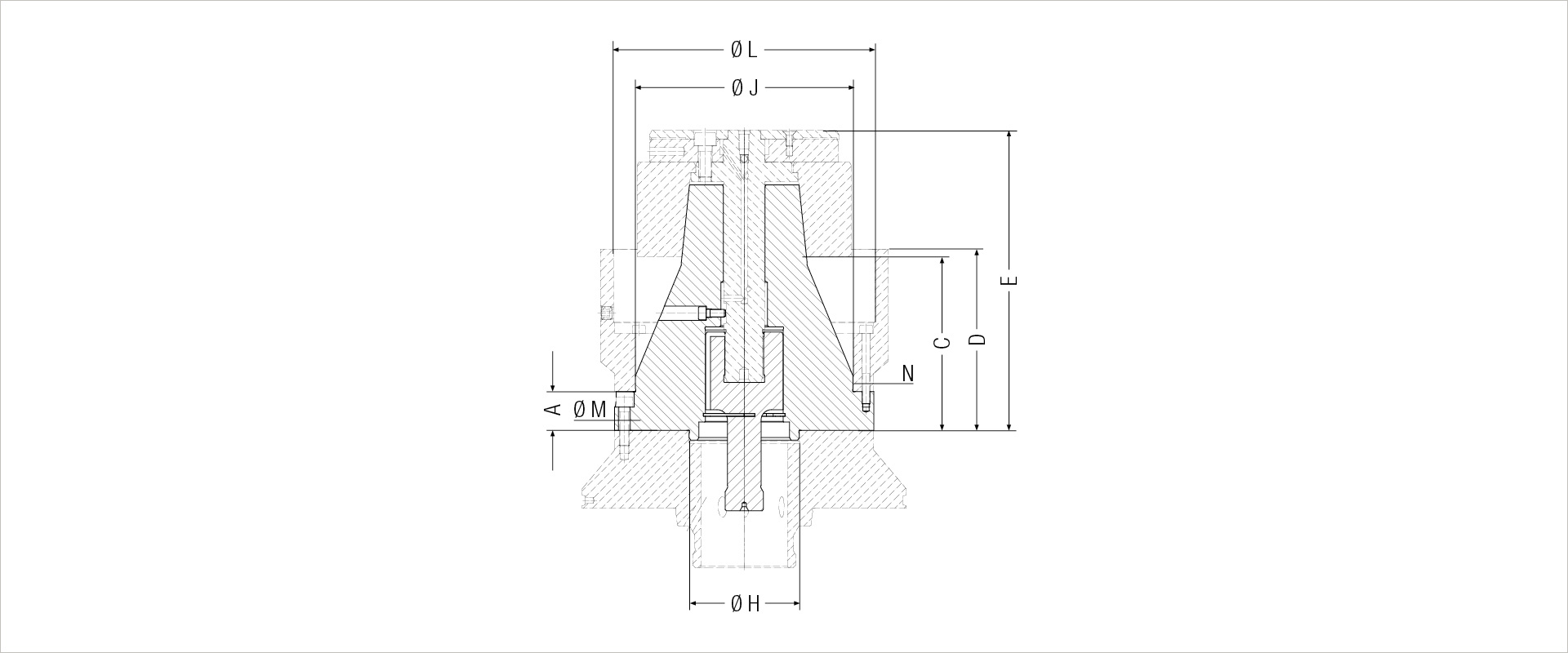

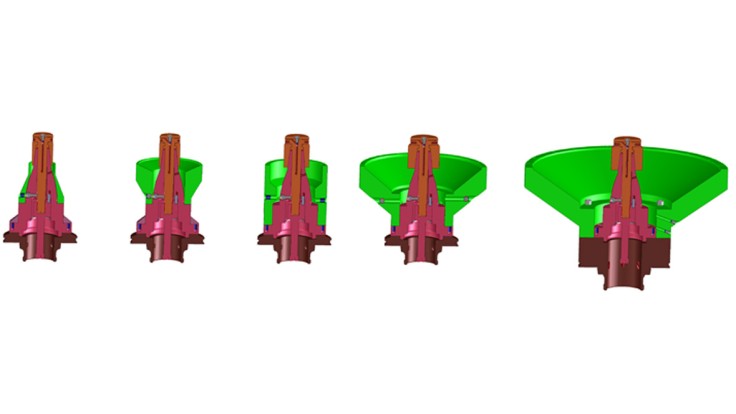

Standard segment clamping arbor

Size 1-4

Optional

- Collision and working area investigation*

- Adapter for Liebherr standard machine table interface

- Suitable grease

* may extend the delivery time

- Suitable tools

- Load handling attachment for ergonomic handling

- Test workpiece and measurement report

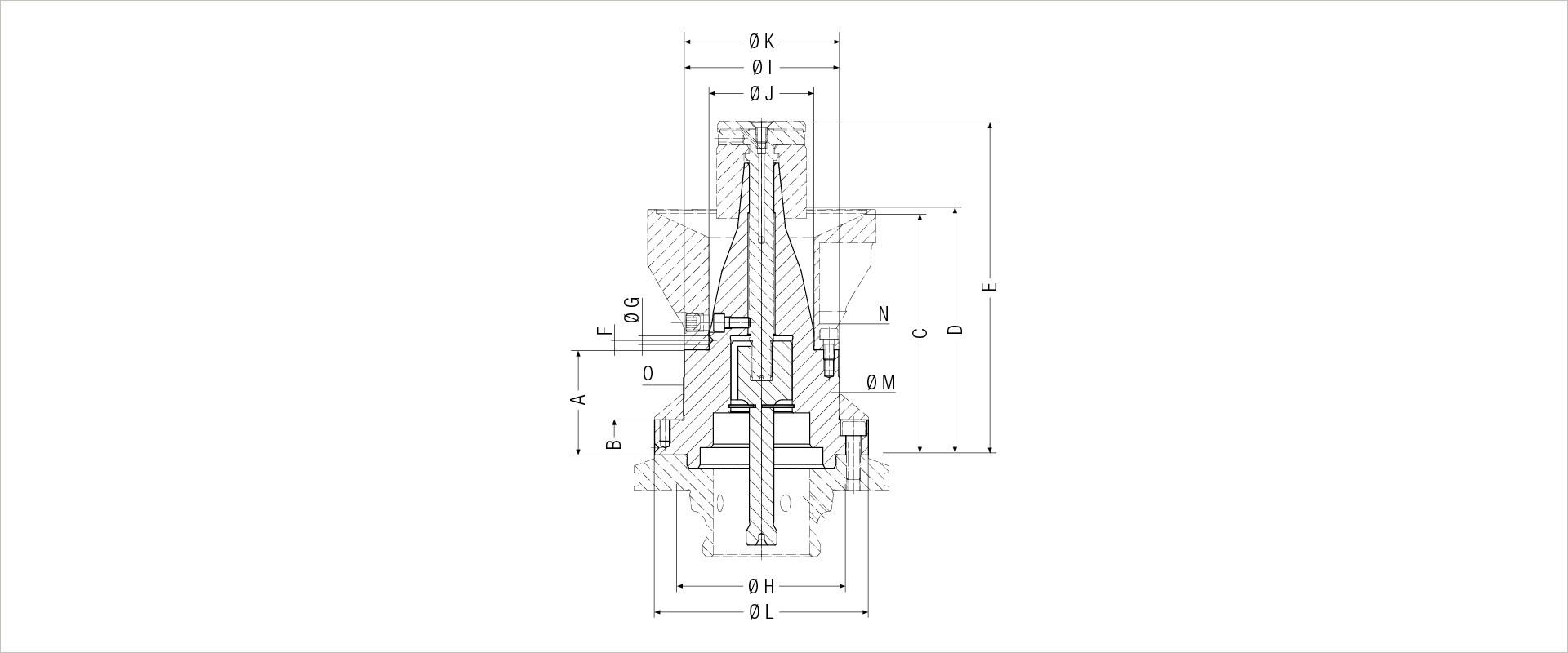

| Size | 1 | 2 | 3 | 4 | |

| Clamping range | mm | Ø 20 - Ø 32 | Ø 25 - Ø 41 | Ø 32 - Ø 51 | Ø 41 - Ø 62 |

| Radial runout | mm | < 0.008 | < 0.008 | < 0.008 | < 0.008 |

| Max. actuating force | kN | 8 | 10 | 12 | 25 |

| Clamping margin* | mm | 1.5 | 1.5 | 1.5 | 2 |

| Release stroke* | mm | 2 | 2 | 2 | 2.5 |

| Max. stroke of the clamping bushing | Ø mm | +0.2 / -0.3 | +0.3 / -0.4 | +0.3 / -0.4 | +0.4 / -0.5 |

| Permitted clamping range** | Ø mm | ± 0.05 | ± 0.1 | ± 0.1 | ± 0.2 |

| A | mm | 80 | 77 | 60 | 60 |

| B | mm | 20 | 20 | 20 | 20 |

| C* | mm | 135 | 135 | 135 | 136 |

| D | mm | 140 | 140 | 140 | 140 |

| E* | mm | 170 | 177 | 190.5 | 198.5 |

| F | mm | 5.5 | 5.5 | 5.5 | 5.5 |

| Ø G | mm | 5 | 5 | 5 | 5 |

| Ø H | mm | 85 | 85 | 85 | 85 |

| Ø I | mm | 60.5 | 69.5 | 88 | 89 |

| Ø J | mm | 32.5 f7 | 41.5 f7 | 60 f7 | 63 f7 |

| Ø K | mm | 89 f7 | 89 f7 | 89 f7 | 89 f7 |

| Ø L | mm | 122 -0.05 / -0.2 | 122 -0.05 / -0.2 | 122 -0.05 / -0.2 | 122 -0.05 / -0.2 |

| Ø M | mm | 9 | 9 | 9 | 9 |

| N | mm | M 6 | M 6 | M 6 | M 6 |

| O | mm | M 6 | M 6 | M 6 | M 6 |

| *for clamping units; mean value of clamping range in “clamped position” | **for clamping unit with nominal bore dimension with tolerance <= IT8 | ||||

Application examples for the clamping system in gear technology

Your contact for the perfect clamping technology solution

We are happy to answer any questions about our clamping fixture.

Service for segment clamping arbor

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten

Germany