Magazine 2020

Magazine 2020

When founding the Industrial Services for Gear Technology and Automation Systems department in 2018, Liebherr already began rolling out the topic of services again from a user perspective. By now, customers can choose the service that fits their individual requirements from a total of five different service packages.

Most read

01

In August 2019, trainees Fabian Altenried and Julia Fetzer participated in the Liebherr Summer Program at Liebherr Gear Technology Inc. / Liebherr Automation Systems Co. (LGT / LAU) in Saline, near Detroit. There, they ran the PLC programming course for pupils of the robotics course from the local high school, which was offered for the first time, and got to know the work routine at the Liebherr site. Fabian reports on his experience here:

02

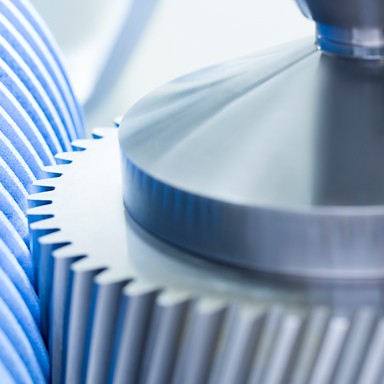

Liebherr presents the new series of generating and profile grinding machines for hard machining of external and internal gears on workpieces with diameters of up to 500 millimeters. The LGG series follows the successful Liebherr LCS 300 to 500 series. With an impressive range of added features, they offer more flexibility and grinding performance with a significantly reduced footprint.

03

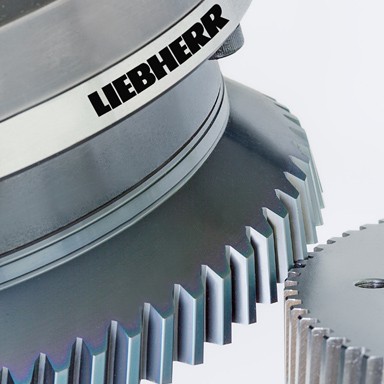

Gear skiving is over 100 years old and has recently been experiencing a renaissance as a flexible and economical alternative to other gear cutting methods. However, this complex process frequently presents great challenges to users. In addition to Skiving3, a “complete package” consisting of machine, tool and technology, Liebherr now also offers skiving tools for suppliers and contract gear manufacturers – and the appropriate consultation, if desired.

Liebherr opened a new test hall for automation systems in Kempten. Prototype solutions are tested and the systems are “put to the test” here. This new facility allows the customers to experience the tests “live” and gives them the opportunity to conduct virtual tests themselves.

x

Close to production, with high cleanliness and air conditioning standards: The two new measuring rooms of Liebherr-Verzahntechnik GmbH at the Ettlingen site are used for quality control during the production of Liebherr gear cutting tools and for contract manufacturing.

A year ago, Wenzel GearTec GmbH, a successful manufacturer of gear inspection machines, was integrated into Liebherr-Verzahntechnik GmbH. How are the customers, technology and employees benefiting from this today? We spoke to Peter Biemer, Liebherr’s divisional Head of Sales Gear Cutting Machines, and Heinrich Brüderle, Head of Measuring Technology, formerly of Wenzel GearTec GmbH.

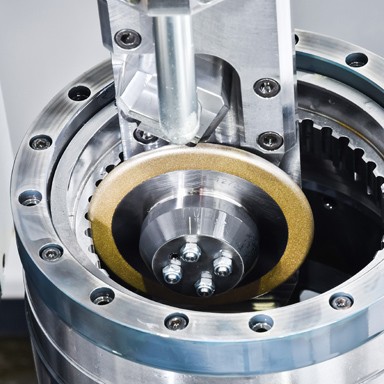

The machining of gears with interfering contours for the aerospace industry places the highest demands on the grinding tool and often cannot be carried out with standard grinding heads due to the small tool diameters. Liebherr has developed an auxiliary spindle for these applications which can be retrofitted. This enables the production of challenging aerospace components on existing LGG gear grinding machines.

Karl-Heinz Klöble is responsible for putting large gear cutting machines into service in China. We spoke to him about his experiences there and what fascinates and motivates him in his unusual job – and why he’s too busy to retire yet.

Liebherr in the United States is proud to celebrate five decades in North America and establish itself as a leading manufacturer. Liebherr has built its U.S. business on a foundation of trust, innovation and engagement with customers. Five decades later, Liebherr’s growth, diversity and stability are evidence of how the company is united by success with customers as they work on the challenges of tomorrow and focus on the future together.

Until now, Liebherr has provided Bin Picking solutions with software supplied by a partner. Now the company offers its exclusive software package with new features that can also be integrated into systems from other manufacturers. Liebherr’s combined expertise in software development and industrial application also makes LHRobotics an interesting product for integrators.