Construction sites are often confusing places. Large machines, restricted fields of vision, loud ambient noise and parallel work processes can make it difficult for machine operators to maintain an overview. This increases the risk of collisions with other machines, obstacles or people in the work area.

Camera-monitor systems and 360° surround view systems are effective solutions for reducing accidents, eliminating blind spots and improving occupational safety on construction sites. These camera systems support machine operators in their daily work, improving visibility around the machine and optimising work processes and efficiency.

On the safe side

The 360° surround view system LiXplore® Bird's Eye not only provides a complete surround view, it also increases work safety and efficiency:

✔ Safer maneuvering and working thanks to a detailed overview of the driving and working areas

✔ Greater efficiency thanks to faster maneuvering and reduced downtimes

✔ Less work accidents thanks to collision prevention

Retrofit your machines with the 360° camera system now!

Advantages of the camera-monitor systems

All-in-one solution

All-round support

More work safety and efficiency

HD image quality

Reliable under the harshest working conditions

Ruggedness is paramount in the design of our camera sets. With all the hammering, drilling and vibration on site, our camera stays in place. At the same time, our systems meet the requirements of ISO 16001 for earth-moving machines with object detection systems and visual aids.

Retrofitting with Liebherr camera systems – our service for you

Find the perfect camera system for your requirements

Whether camera-monitor systems or 360° surround view systems – our fully digital HD camera systems reliably ensure a clear view and a better overview.

| LiXplore® CMS Camera-monitor system | LiXplore® Bird's Eye 360° surround view system | |

| Amount of cameras | 1-6 | 4 |

| Field of view (HFOV) | 120° , 150° | 150° |

| Display sizes | 9 inch , 12 inch | 9 inch , 12 inch |

| Views | Gallery mode Single cam | Top view Single view |

| Overlays | ✔ |

Your first steps

Frequently asked questions

Both the LiXplore® Bird's Eye surround view system and the camera-monitor system are suitable for retrofitting a wide variety of machines and vehicles.

However, their area of application extends far beyond construction machinery. Our camera systems also enhance the efficiency of mobile work machines used in agriculture, forestry, off-road work, material handling, waste disposal and special vehicles. Examples include field sprayers, harvesters, reach stackers and municipal vehicles.

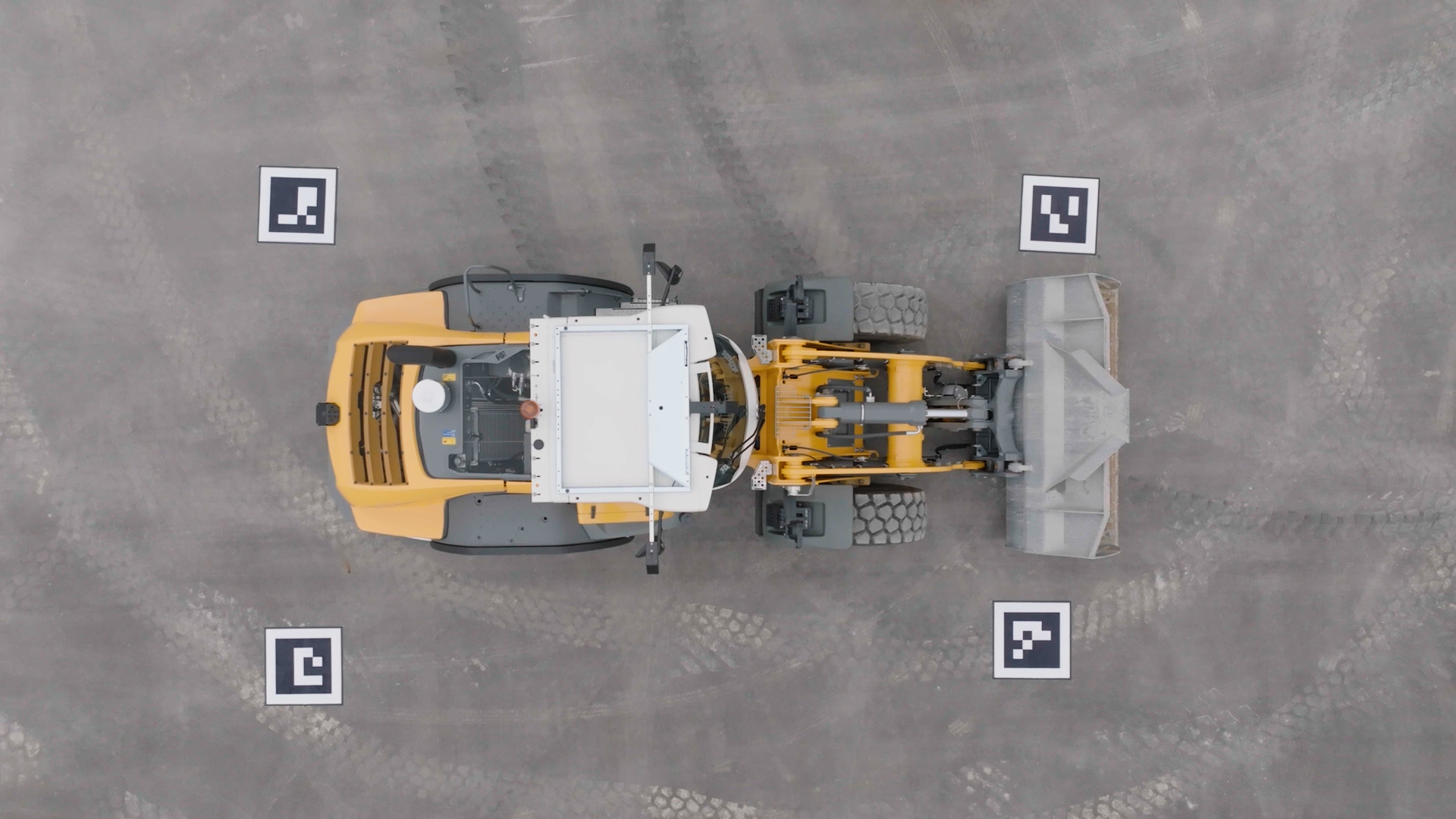

Retrofitting is carried out in several steps. First, the optimal camera positions are determined either empirically or using a field of view analysis. The cameras are then configured and mounted. Calibration mats are laid out to ensure accurate display of the camera images, and the system is calibrated. Finally, the system configuration is created on the machine.

As a rule, retrofitting a camera system does not require long periods of machine downtime. Installation, system integration and calibration can usually be completed in a short amount of time. This keeps downtime to a minimum and minimises the impact on ongoing operations.

Get in touch

We would love to hear from you

Phone: +49 8382 2730 4241

- To the contact form