Mining

MiningPress releases | 02/18/2025

Liebherr to present its latest mining solutions at Bauma

- From 7 to 13 April, the Liebherr Group will be at the Bauma exhibition in Munich, Germany

- Liebherr will display the new autonomous, battery-electric T 264 mining truck with both static and dynamic charging solutions, the R 9400 E electric excavator fitted with Liebherr cable reel, and the latest IoMine technology and service solutions

- Visitors attending Bauma in person can attend daily live demonstrations to see the equipment in action

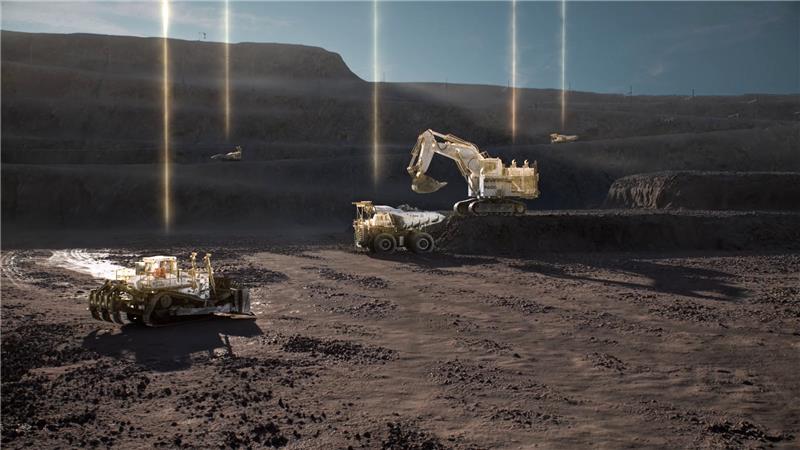

At this year’s Bauma, Liebherr will present its latest solutions for the mining industry, including the autonomous battery-electric T 264 haul truck; the R 9400 E electric excavator; the new integrated technology portfolio, IoMine; and a range of comprehensive service solutions. Aligned with Liebherr’s event motto, ‘Hands on the Future’, the mining product segment’s display will showcase how collaboration with industry partners drives innovative solutions for tomorrow’s challenges, pushing the boundaries of what is possible.

Colmar (France), 18 February 2025 – Liebherr will share its latest news, products, services and innovations for the mining industry at this year’s Bauma – the world’s leading construction machinery exhibition – from 7 to 13 April at Messe München in Munich, Germany. Visitors can see the impressive autonomous, battery-electric T 264 mining truck and R 9400 E electric excavator up close during daily live demonstrations and can also discover the latest mining technology and service innovations in the Mining Technology Pavilion.

Autonomous, battery-electric T 264 mining truck: pioneering mining decarbonisation

The autonomous, battery-electric T 264 mining truck not only represents the culmination of years of hard work and the joining together of the autonomy and zero emission arms of the Liebherr–Fortescue partnership but also showcases the value of working hand-in-hand with industry partners. The autonomous, battery-electric T 264 has a 3.2 MW battery, which was developed by Fortescue Zero – Fortescue’s battery technology arm.

The battery-electric truck supports both static and dynamic charging, both of which will be showcased at Bauma. Fortescue’s stationary fast charging solution delivers up to 6 MW of power, enabling the current battery-electric T 264 to charge in 30 minutes. Also on display will be Liebherr Power Rail, a class-agnostic dynamic charging concept based on Liebherr’s proven trolley bar technology.

The truck on display at Bauma will also be equipped with the Autonomy Haulage Solution (AHS) that was developed as part of the Liebherr–Fortescue partnership. Within the AHS is an Energy Management System that coordinates the static recharge assignments for these trucks and ensures the charger is fully utilised without causing queuing on site.

R 9400 E: more than 40 years of E-xperience

The R 9400 E 350-tonne electric excavator will also be on display at this year’s Bauma, showcasing Liebherr’s commitment to decarbonisation. This machine reflects over 40 years of Liebherr’s expertise in electric excavator development and manufacturing while incorporating the latest innovations from the mining product segment. The excavator on display is also equipped with Liebherr’s cable reel solution, which offers up to 300 metres of autonomous cable management to enhance manoeuvrability and ensuring efficient cable management for increased operational flexibility.

Mining Technology Pavilion: more than machines

At the Mining Technology Pavilion, visitors will be able to discover the latest from the IoMine technology portfolio and Liebherr’s mining service offerings.

IoMine, Liebherr’s updated and expanded technology portfolio, features cutting-edge technology designed to optimise all aspects of day-to-day mining operations. The products within IoMine are split into three distinct product families, each dedicated to a specific aspect of mining operations: Operate, Automate and Maintain. Operate products are designed to streamline and improve day-to-day mining activities by collecting, analysing and leveraging data from Liebherr machines. The Automate product family provides customers with both full and semi-autonomous solutions for their fleets. And the solutions within the Maintain product family are designed to streamline issue resolution for onsite personnel.

Remote Service is one of the company’s latest service offerings and falls within IoMine’s Maintain product family. It enables onsite technicians to connect with Liebherr experts for streamlined maintenance and repairs. At the Mining Technology Pavilion, visitors will be able to experience Remote Service for themselves and explore the rest of the company’s comprehensive service solutions, which range from initial equipment consultation to machine maintenance, customer support and equipment upgrades. Additionally, Liebherr will showcase the latest updates to its Support, Parts and Upgrades services at Bauma, demonstrating the company’s commitment to partnering with customers throughout the entire life cycle of their products.

Contacts

Liebherr Mining Equipment Newport News Co.

Newport News, VA 23607

United States of America