We keep the industry moving

System solutions for machining manufacturing

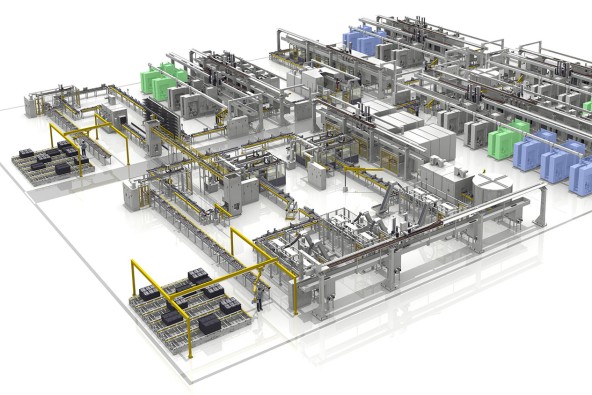

Planning a manufacturing line can be highly complex. With Liebherr at your side, you have an experienced partner with great process and system expertise. We have proven and established ourselves as a reliable automation supplier with strong references in the automotive industry. Manufacturing lines from Liebherr are in use all over the world and ensure optimal production of large quantities of units. Our broad portfolio enables flexible system configuration with maximum productivity.

Discover our product portfolio

Gantry robots

Liebherrs gantry robots can be used in multiple ways. A modular system means the automation system can be custom adapted.

Conveyor systems

Liebherr produces tailored conveyor systems. The high level of vertical integration enables us to implement customer wishes exactly.

Additional devices

Liebherr helps their customers solve complicated tasks. We draw on a large scope of additional services to do this.

Turnkey systems

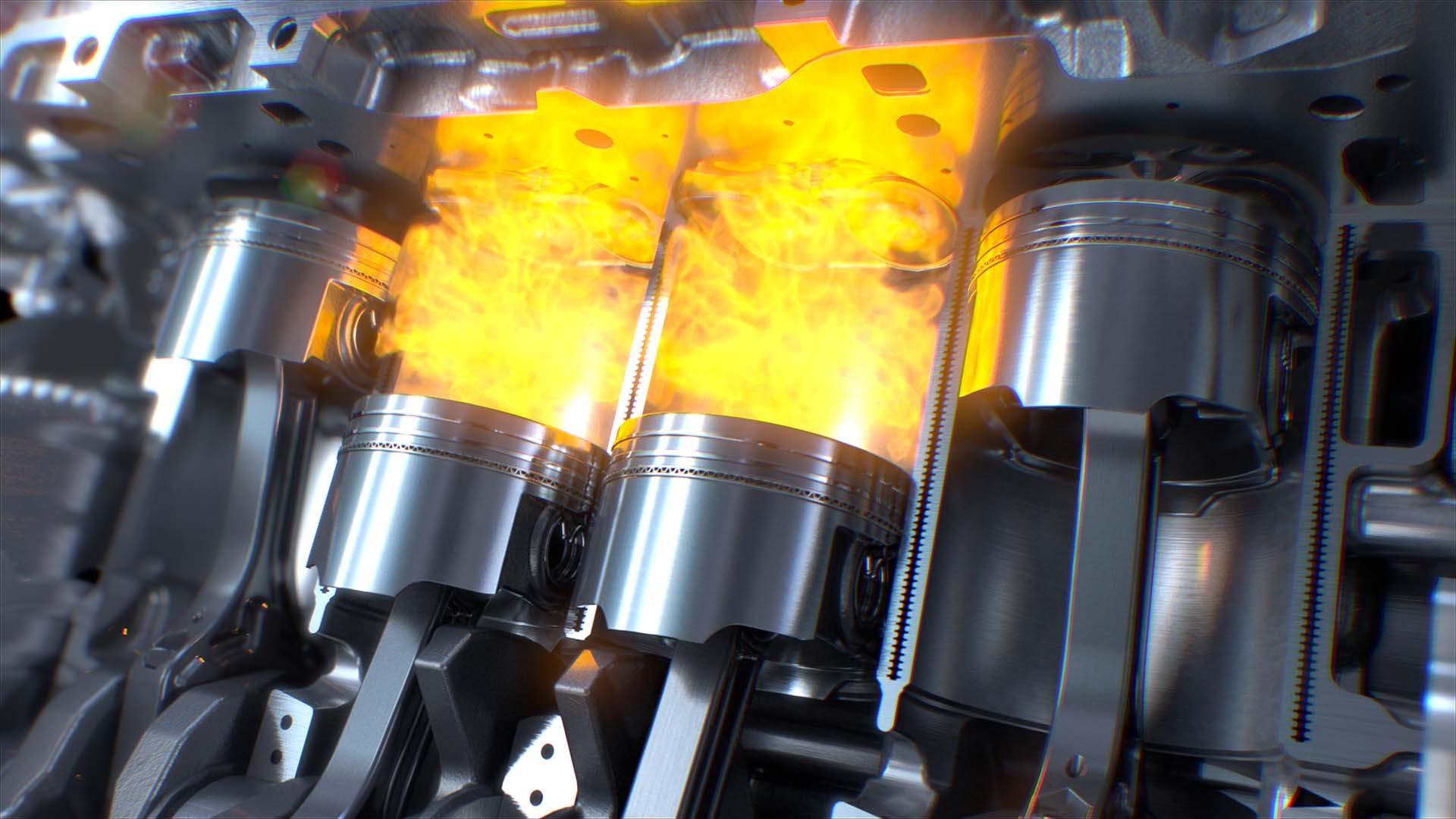

Automated manufacturing systems enable the precise mechanical machining of workpieces for the conventional powertrain. The focus here is to reduce system auxiliary process times and optimize system availability.

The production design involves CNC machines working in parallel in standardized manufacturing cells. Each machine in the cell performs specific machining steps. Engine blocks, cylinder heads or gearbox housings are machined in the area for cubic parts using gear cutting, honing, drilling and thread cutting to give them the desired shapes and dimensions. Rotational and grinding processes are used when machining cylindrical workpieces like crank shafts or camshafts.

The number of machines in a cell depends on the cycle time and number of machining operations. Additional machines can be added easily. Using adapter plates means new types of workpieces can be integrated without costly retrofitting work. Conveyor belts generally facilitate material flow between the cells.

The linear gantry allows unimpeded access to the machines while sliding hatch covers ensure safe access even in Automatic Mode. Maintenance work can therefore be performed without interrupting production and keeps more systems available. Workpieces can be unloaded and loaded for quality assurance using SPC spaces.

Application examples

Liebherr - Liebherr Manufacturing System LMS 4.0

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Further information

Read interesting articles from our customer magazines:

Your contact for automation solutions for the conventional powertrain

We're happy to answer any questions you have on systems and system solutions for machining manufacturing.

Uwe Radigk

Head of Global Key Account Management Automotive

Liebherr-Verzahntechnik GmbH

Kaufbeurer Straße 141

87437 Kempten

Germany

Phone: +49 831 786 1160

Cell phone: +49 160 749 4389

Email