7 minutes | magazine 02/2018

Powerful!

New crawler crane, new transport concept, new ballasting system, new model designation – and truly powerful as well. Liebherr unveiled the LR 1800-1.0 crawler crane at its customer days in 2018. In its basic concept, the 800-tonne crane is designed for jobs in industry.

Klaus Huberle, General Manager Crawler Cranes

Tailored for power

The new LR 1800-1.0 power pack is designed for maximum power and delivers outstanding lifting capacities. It has a passion for jobs involving a luffing jib and derrick system in industry, for power plant construction or in petrochemicals. Wind power is another of its strengths. After its initial unveiling at the customer days, Liebherr will exhibit the new crane as a highlight at Bauma 2019 in Munich.

Klaus Huberle is one of the experts when it comes to lattice boom cranes at Liebherr. In the role of Manager of Technical Sales for Crawler Cranes, he and his team initiate the design of new crane models and systems in close cooperation with the design departments. He says: “I was delighted to receive such a positive response at the customer days after we unveiled our 800-tonne crane. You can see that this is a really good concept with several innovative features.”

One of the main features of the 800-tonne crane is its extraordinary performance. The Liebherr designers focused on the rigidity of the basic machine and developed the individual components with a greater design height for this purpose. Furthermore, the lower section of the main boom has a wider design. This enables the LR 1800-1.0 to achieve particularly high lifting capacities.

The Russian doll principle

“Low-cost transport ideas are becoming more and more important to our customers”, says Klaus Huberle and continues: “We looked for new solutions and for the 800-tonne crane, we developed three system dimensions for the standard crane for the first time. These are simply pushed inside each other for transport. In principle, just like a Russian doll.”

Regular contact with customers in his department goes well beyond simply selling cranes. Receiving input from practice is an important source of information. Huberle emphasises: “We talk to our customers about the challenges of everyday

practice and look for possible designs together. That means that we know what the problems are and we react by developing new solutions.” The three system dimensions for a boom length of 96 metres for the main boom and 96 metres for the luffing jib means that five complete transport units can be dispensed with. The basic LR 1800-1.0 machine is just 3 metres wide and weighs 45 tonnes – perfect values for low cost transport.

The LR 1800-1.0 is the most powerful 3-metre crane on the market. Our focus during the product development phase was firmly on achieving maximum power.

Folding the first: Suspended ballast with an adjustable folding frame

Lights, camera, action – for extremely innovative and highly flexible derrick ballast. The LR 1800-1.0 features a new type of ballast system – the V frame is a hydraulically adjustable folding frame. It enables enormous adjustment distances of between 14 and 23 metres. That delivers maximum flexibility compared to the standard rigid system for large ballast radii. With good job planning, the V frame creates an enormous range of uses and makes it possible to dispense with ballast transport.

The LR 1800-1.0 also features VarioTray – a small part of the derrick ballast can be unbolted quickly and easily. This small part is generally sufficient for hoisting work with the boom fully raised. The large ballast pallet is often only required to raise and lower the boom. This means that there is no need to stack and unstack the ballast slabs – VarioTray saves an enormous amount of time and money.

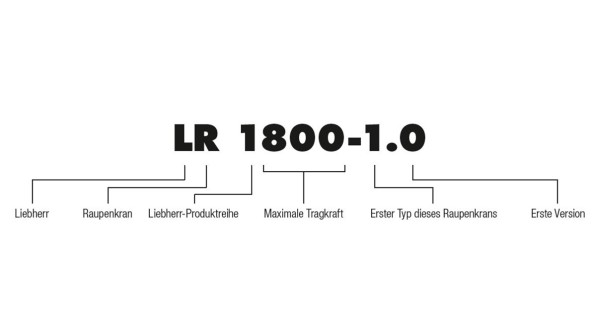

New crawler crane designation

This new crane model also saw Liebherr introduce a new suffix to the model name for crawler cranes: The "1" after the hyphen stands for the first model of the 800-tonne crawler crane. The "0" after the dot means the first version – this number will be incremented by 1 with each major technical modification in the future.

This article was published in the UpLoad magazine 02 | 2018.