Technical spotlight: Liebherr Power Efficiency

Fuel consumption is a constant preoccupation for mining companies. It’s a major source of greenhouse gas emissions, as well as a massive part of operational expenditure. Liebherr Mining seeks to alleviate these issues through Liebherr Power Efficiency – the company’s proprietary engine and hydraulic control systems for its excavators.

In recent years, there have been a number of impressive innovations in the zero emission technology and alternative fuels spaces, helping mine sites to drastically decrease their fuel consumption. However, these innovations are not yet suitable for all mine sites around the world. In some regions it’s not possible to rely on solutions like hydrogen, electrification or battery technology. Adequate infrastructure may not yet be in place, or the price of these power sources may be too expensive to be feasible. As such, it is vital that OEMs (original equipment manufacturers) like Liebherr Mining keep finding ways to optimise the systems in diesel-powered machines to keep fuel costs and greenhouse gas (GHG) emissions to a minimum. Liebherr Power Efficiency (LPE) is one such optimisation. These engine and hydraulic control systems can significantly reduce the amount of fuel consumed – and therefore the amount of GHG emitted – by Liebherr’s excavators. LPE can also extend component service life while maintaining the productivity and reliability of these machines.

Designing LPE

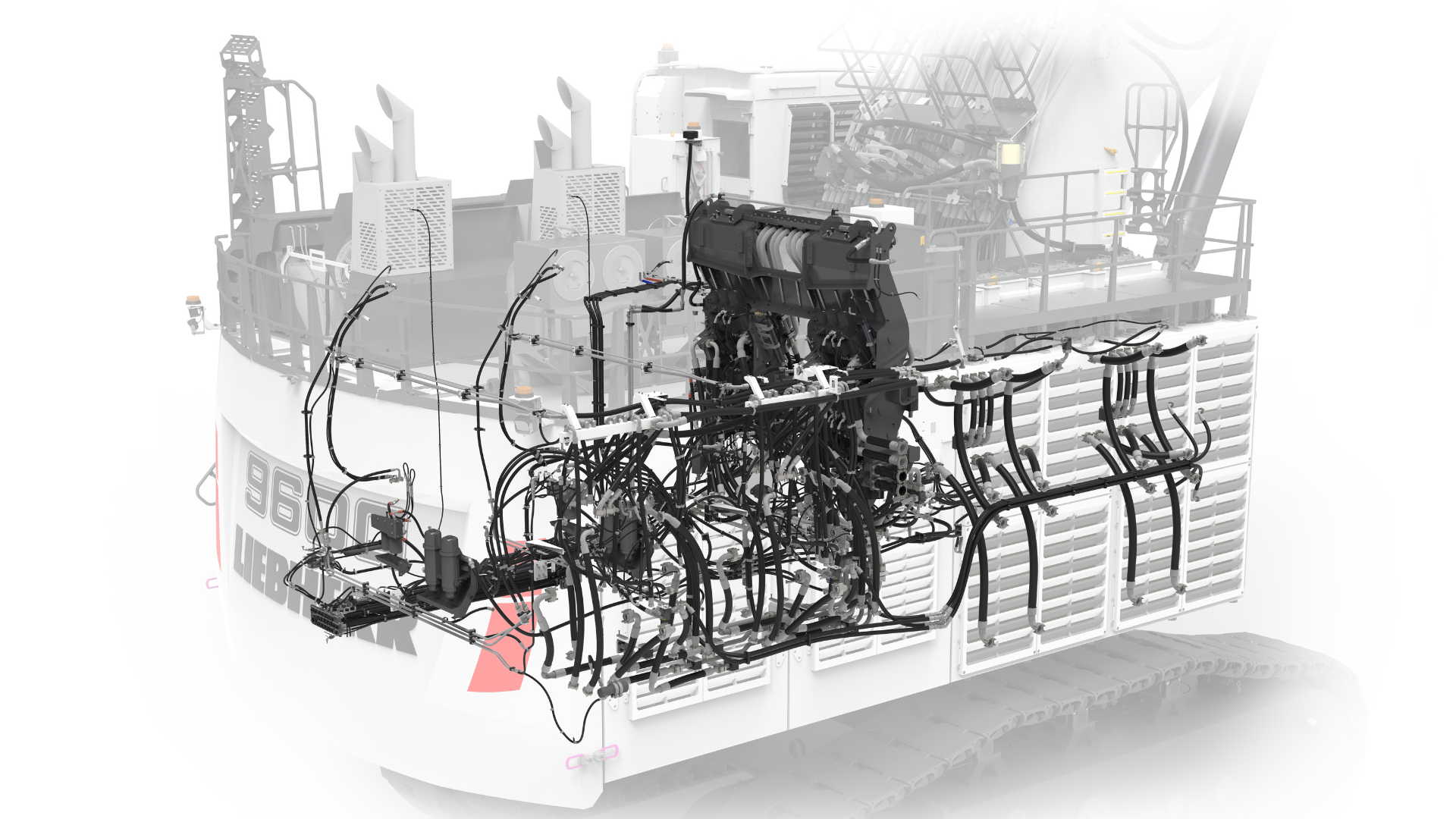

When designing the LPE systems, Liebherr’s engineers wanted to create a solution that would extract maximum energy efficiency from the excavators’ existing power transmission chain, instead of implementing additional systems that can often be complex and costly. Liebherr’s engineers used their in-depth knowledge of the different applications in which the company’s excavators are used – as well as their understanding of energy losses in the excavators’ powertrains – as the basis for LPE. The LPE systems are made up of two different solutions: LPE Engine Control and LPE Hydraulic Control.

LPE Engine Control

There are multiple working phases within an excavator’s digging cycle, and they often have different energy requirements. It’s within these different phases that excavators can burn a lot of unnecessary fuel. To keep this from happening, Liebherr’s patented LPE Engine Control targets the working phases with highest specific fuel consumption. Using a combination of sensors and piloting and electronic signals, LPE Engine Control analyses the operator’s commands and adapts the engine’s RPM to each working phase. This ensures that the engine always operates within its optimal operating range and therefore reduces fuel consumption.

LPE Hydraulic Control

LPE Hydraulic Control keeps losses within the hydraulic circuit – such as throttling and linear losses – to a minimum. A combination of enhanced hydraulic hardware and specialised software adapts the rate of oil flow to match operator requirements and distributes hydraulic power according to load profile – or how hard the engine needs to work at any given time. By adapting the oil flow rate to each working phase, LPE Hydraulic Control reduces the engine’s overall load factor, which helps extend the life of all components within the powertrain, while also decreasing pressure losses and heat generation. LPE Hydraulic Control can also be used on the latest generation of Liebherr’s electric excavators to reduce electricity consumption by a similar amount.

The whole package

LPE comes standard on all Liebherr excavators with an internal combustion engine or electric motor from Generation 7 onwards. Observations of LPE have consistently shown that, when the engine and hydraulic control systems work together, they reduce fuel consumption by up to 20 %. Plus, because LPE reduces the overall load on all powertrain components, the service life of these components is considerably longer in excavators equipped with this system. Thus, these benefits can help mining companies reduce their operational expenses by minimising fuel consumption and maximising service life, all while reducing GHG emissions.