Space-saving

User-friendly

Highest quality

Versatile

The manually loaded LC 400 M gear hobbing machine provides Liebherr quality with maximum flexibility and short delivery times.

The use of premium components and high-performance drives ensures the highest quality results over the entire product life cycle. Due to the extremely compact machine structure, only a small footprint is required. The machine also offers high productivity and a wide range of components at low acquisition cost.

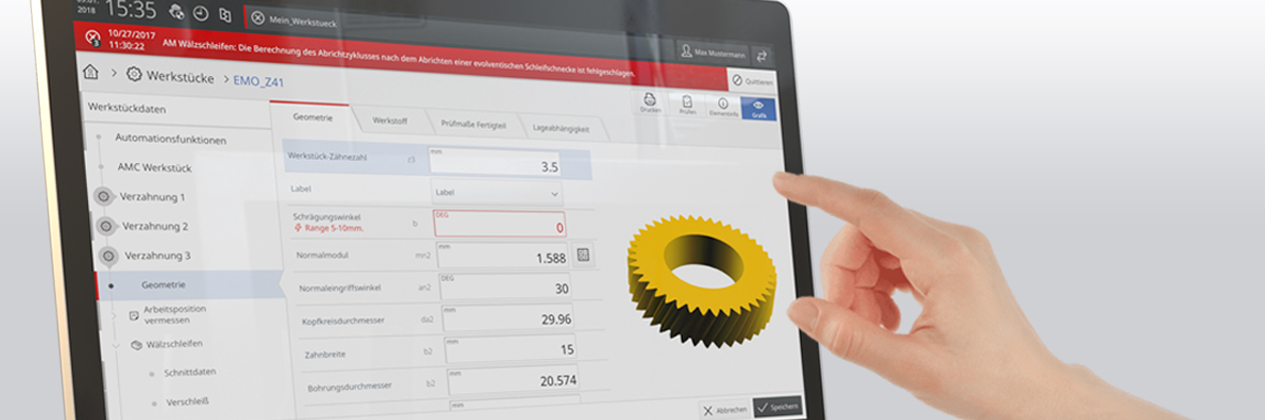

The LC 400 M is delivered as standard with a state-of-the-art operating concept and touch based LHGearTec user interface.

Highlights

- Machining workpieces with max. 400 mm diameter and shafts with length of up to 650 mm

- High rigidity ensures best machining quality

- Thermally stable machine bed with perfect chip removal

- Direct driven machine table for highest quality requirements

- Wet machining as standard

- L-doors for perfect accessibility and crane loading from above

- Available with a handling device (crane) as option

- Extensive software included as standard

- Hook-ready machine for fast installation and commissioning

- Extremely compact footprint

- Optimal accessibility for maintenance and servicing

- Short delivery times and low acquisition cost

Maximized operator friendliness

01/03

Technical data

| Module | 8.00 mm |

| Workpiece diameter | 400 mm |

Video