Engineering expertise for hydraulic cylinders

With innovative products and highly modern production systems, Liebherr has the credentials of a technological pioneer for hydraulic solutions. At the Kirchdorf site, we have an impetus behind innovations. Numerous certifications represent the high quality of our products.

Innovation strength from sound production processes

Liebherr safeguards its high quality standards through sturdy, reproducible production processes. Highly modern CNC machining systems are used to achieve this. We continue to further develop our production processes. This innovation strength is reflected in our products.

View of modern machine park at Liebherr

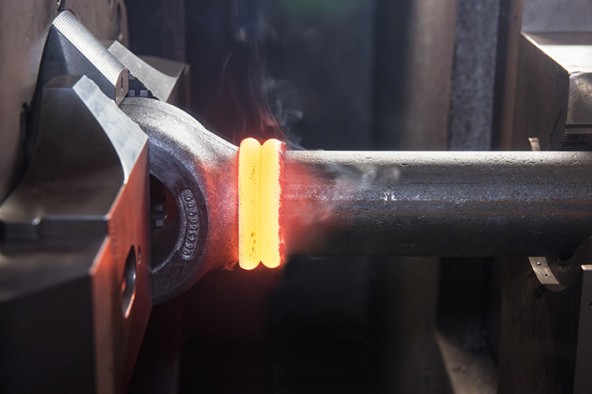

Engineering expertise - friction welding

Friction welding technology

To manufacture hydraulic cylinders, we employ innovative friction welding technology. This makes it possible to weld a whole range of different materials. Numerous combinations of rod heads and round material diameters result in an exceptionally broad product portfolio. As a customer, you profit from high availability and cost efficiency.

Approved quality: certifications

The numerous certifications are testament to Liebherr's high standard of quality. Aside from the usual ISO standards of the quality management system, Liebherr has the following certifications:

- ISO 9001:2015

This norm forms the basis for our QA system and the ongoing improvement process within the company. - EN 1090-2.00302.GSIMue.2016.003 in accordance with EN 1090-1

This certification qualifies us to weld and produce steel support structures. These serve, for example, as earthquake protection in nuclear power stations. - DGRL 97/23/EG – AD 2000

This certification controls the manufacture of pressurised equipment. - Certification according to American Society of Mechanical Engineers (ASME) - Kirchdorf and

Certification according to American Society of Mechanical Engineers (ASME) - Oberopfingen

This certification controls the manufacture of pressurised equipment according to the rules of the ASME for the global market. - DIN EN ISO 3834-2:2006

This norm defines the extensive demands on quality for fusion welding metallic materials.

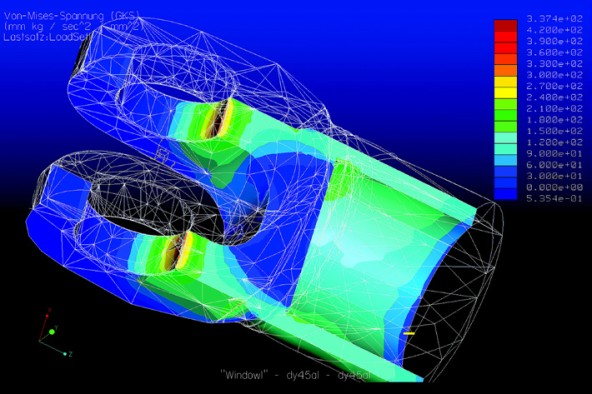

Modern calculation methods

The design and calculation of our cylinders is application-specific according to the relevant applicable standards and regulations e.g. AD 2000, ASME and DIN/ISO. For the calculations, we rely on highly modern analysis and simulation software such as Ansys for FEM analysis. Our cylinders undergo approval inspection as required in co-operation with renowned approval inspection and classification authorities.