Technical spotlight: Assistance Systems for mining trucks

At MINExpo 2021, Liebherr launched a new range of semi-autonomous Assistance Systems for its mining truck portfolio. These systems included the Trolley Navigation Assist and the Crusher Navigation Assist and were designed to increase operator safety, productivity, fuel efficiency, and to protect customers’ machines from unnecessary damage. At the 2022 Bauma exhibition, both Assistance Systems were showcased inside the Liebherr Mining technology pavilion so that visitors could take a closer look at this new technology in action.

Site infrastructure

For these Assistance Systems to work on a mine site, they need to leverage a site’s existing Global Navigation Satellite System Real-Time Kinematic (GNSS RTK) base station technology. Both systems rely on high-precision GNSS units to perform their respective functionalities. GNSS units use the location correction information collected from the base station to calculate the precise position of trucks on site with centimetre-level accuracy. This level of accuracy is crucial when trucks weighing hundreds of tonnes perform delicate manoeuvres such as connecting to a thin trolley line in the right place or reversing into a narrow, fixed structure.

Planning missions

A valuable component of both of Liebherr’s Assistance Systems is Mission Planner Software (MPS), a computer-based software developed and owned by Liebherr Mining. The MPS allows customers to create missions that both the Trolley Navigation Assist and Crusher Navigation Assist can then execute. A mission is a collection of information that dictates where a truck can travel on site as well as which areas of the mine site require the Assistance Systems to perform particular functions. These functions can include raising a truck’s pantograph or sending a notification to the operator to take their hands off the steering wheel.

The MPS allows for survey images of a customers’ site to be directly imported into the program. The customer can then use these images to accurately map out locations where the missions for each Assistance System will be carried out. After the customer has created these missions and included all relevant information – such as speed limits for path segments and where trucks need to connect to the trolley line – details are then packaged together and sent to Liebherr’s cloud platform. Once the details are saved within the cloud platform, the mission information can be retrieved by a certified Liebherr technician and loaded onto the truck. These original missions will remain installed in the trucks for as long as they have an Assistance System installed. If these missions need to be altered, customers need to ensure that the yearly maintenance fee has been renewed in order to update the system data.

While both the Trolley Navigation Assist and the Crusher Navigation Assist share similar technological foundations, the ways that these are utilised in each Assistance System are quite different.

Trolley Navigation Assist

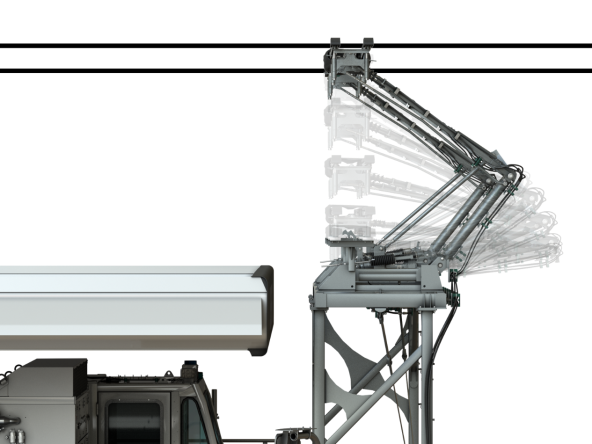

To understand how the Trolley Navigation Assist (TNA) works, it is important to first know what a trolley system is. A trolley system is a power delivery system that allows mining trucks to use electricity from fixed electrical infrastructure as their power source, rather than using a diesel combustion engine. The trucks connect to the trolley line via a pantograph and collect the energy needed to move the machines via this connection. However, it can be difficult for operators to connect successfully to the trolley line, given the small size of the target. Moreover, it can be difficult for operators to maintain a consistent travel path while connected to the trolley.

This is where the TNA can help.

The TNA leverages a mine site’s existing GNSS RTK base station and radio frequency identification (RFID) technology to identify the right time to automatically raise and lower the trucks’ pantographs and to steer trucks while connected to the trolley line. The onboard GNSS unit stores the location data of the trolley line and compares this to the position of the trucks. The TNA will then make steering corrections to keep the trucks aligned with the trolley line. The RFID technology is a secondary system that helps to control the pantograph and its connection to the trolley line. Once the system has been installed, the customer can create trolley guidance missions using a combination of the imported site survey imagery, landmarks known to the survey team, and the trucks’ overall operating area. The MPS allows the customer to designate different areas of the mine site as signifiers for when the TNA needs to take certain actions. Within the software, the customer can highlight which area on site is the “operation area” for the TNA and thus, when this system needs to come online. Inside that area, the customer can nominate the “hands off area” for when the system needs to notify the operator – via audible chime and visual cues on the TNA screen – to remove their hands from the steering wheel. This is when the TNA would take control of the truck and guide it to the appointed “starting area”, where the system will raise the pantograph to connect to the trolley line. The truck will then steer itself along the trolley line in the operating area until it reaches the place that the customer has designated the “ending area”. Here, the system will automatically disconnect the pantograph from the trolley line and alert the operator that it is time to take control of the truck once more.

Customers can allocate alternate access points along the designated trolley path to accommodate times when the operator needs to disconnect their truck from the trolley. For example, if the path is blocked due to a stalled truck or spillage, the operator can deactivate the TNA, travel around the blockage, and can reactivate the TNA at a predetermined alternate access point. Alternate access points can also be used in instances where trucks need to enter the trolley line from an intersection within the line. The TNA can maximise trucks’ time under trolley by ensuring that they are connected to the line properly and can automatically follow the trolley line’s path. This results in a reduction of the fuel consumed by the trucks. Further, the TNA can help to reduce the pressure on operators to keep the trucks perfectly in line with the trolley, thus ensuring increased efficiency and decreased operator stress and fatigue.

Crusher Navigation Assist

The Crusher Navigation Assist (CNA) helps operators to successfully reverse their mining trucks into a fixed, and often narrow, structure such as a crusher. To do this, the system relies on a foundation of high precision GNSS and ultrasonic technologies to reverse trucks safely and accurately into these tight spaces. The GNSS provides the guidance system with the exact geospatial location of the relevant trucks. The ultrasonic technology is a secondary system that ensures that the trucks stop in the right place to safely dump their loads into the crusher.

After the CNA has been installed, the customer can use the MPS to map out the pathway the trucks will need to take to reverse into the crusher safely. If needed, the customer can map out multiple unique crusher missions within the MPS, each with its own designated travel path and specific speed characteristics.

Within the map of their site in the MPS, the customer can nominate the “operating area” which will determine the scope of the CNA's influence. Within this area, the customer will also designate the “staging area”, which is where the CNA is activated. From this area, the customer will then plot out the reversal path that trucks need to follow to reverse safely into the crusher. When operators enter the area and navigate onto the path, they will be notified via audible chime and visual cues to remove their hands from the wheel as the CNA will then be in control.

The reversal pathway is comprised of two sections: the forward motion and the reversal motion. The forward motion is when the system is steering the trucks so they are properly aligned with the crusher. Once this motion has concluded, operators will need to put the trucks in reverse so that the reversal motion can begin. Towards the end of the reversal motion, the CNA will alert operators – via audible chime and visual cues – when the guidance system has completed the mission successfully. After completion, operators will be advised to place the truck in neutral and set the handbrake. The CNA will then advise via visual indicator that it is fine to dump the trucks’ load.

Using the CNA helps to reduce the risk that the trucks may be damaged during the reversal process while also decreasing cycle times. This in turn will allow for increased productivity on site and reduced stress for the operators.

Installation and integration

Liebherr’s Trolley Navigation Assist and Crusher Navigation Assist are available for the T 264, T 274, and T 284 mining trucks and have been extensively field tested to ensure their efficacy when used in customers’ mining fleets. Both of these Assistance Systems are designed to serve as individual solutions to specific inefficiencies within a mine or to serve as a combined solution for multiple mine challenges.

Liebherr’s Assistance Systems can be retrofitted into trucks that are already operating on site. And if a truck already has one of these Assistance Systems installed, the second one can be installed later in the life of the machine. An additional kit can be provided with the harnesses and sensors necessary for the new system to work alongside the system already installed.

This impressive technology is ready to be integrated into Liebherr mining trucks to ensure that customers can make the most out of their equipment while also ensuring the safety and wellbeing of their staff.