E-drive for mobile harbour cranes

We are confronted with the topic of greenhouse gas reduction on a daily basis. In addition, both legal regulations and social demands place specific requirements on the manufacturing industry to conserve resources and minimise CO2 emissions. Consequently, the transition to environmentally friendly drive types has long been essential.

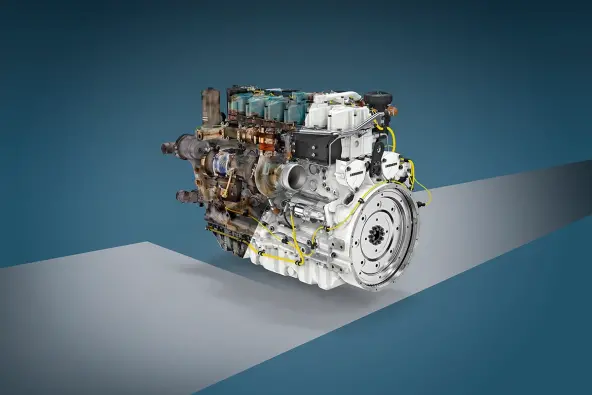

Our electric drive enables you to operate your crane locally emission-free. Of course, an e-drive can be installed in a new machine from the beginning, but even as a retrofit kit the conversion of a diesel to an electrical drive offers significant benefits.

Transform your machine to dispense with fuel in your daily work and you will make your business more sustainable while also reducing operating costs.

Your benefits

Zero CO2 emissions

Reduction of costs

No fuel and lubrication

Significantly reduced noise

Flexible drive systems for mobile harbour cranes

Liebherr offers various types of electric drive systems for its mobile harbour cranes, making an important contribution to improving energy efficiency and reducing emissions in the maritime industry.

- Electric-hydrostatic drive

- Diesel-hydrostatic drive

The electric-hydrostatic drive has technical similarities to the all-electric drive. This drive type is connected to the local power grid, too. That allows for locally zero-emission operation. The drive concept offers two ways of energy recuperation. The energy recovered during lowering can be fed into the local power grid or alternatively stored in the hydraulic Pactronic system to be retrieved when needed.

The Pactronic system consists of a powerful hydro-pneumatic storage, which temporarily doubles the primary power for highly efficient crane operation. Both options reduce operational costs compared to conventional drive systems. The main gear uses a closed hydraulic system to ensure maximum drive efficiency.

The electric-hydrostatic drive has technical similarities to the all-electric drive. This drive type is connected to the local power grid, too. That allows for locally zero-emission operation. The drive concept offers two ways of energy recuperation. The energy recovered during lowering can be fed into the local power grid or alternatively stored in the hydraulic Pactronic system to be retrieved when needed.

The Pactronic system consists of a powerful hydro-pneumatic storage, which temporarily doubles the primary power for highly efficient crane operation. Both options reduce operational costs compared to conventional drive systems. The main gear uses a closed hydraulic system to ensure maximum drive efficiency.

Get in touch

High voltage versus low voltage

For emission-free operation of your mobile harbour crane, you can choose two options depending on the harbour infrastructure. Connect your crane to a low voltage network from 400 volt or a high voltage network up to 20,000 volt. In case you use a high voltage supply, a converter installed on the undercarriage transforms high to low voltage. Thus, only low voltage is present in the crane itself.

One cable drum, different solutions

We offer the option of a cable-reeling drum for the safe movement of the crane with the cable. Cable length can accommodate customer requirements depending on the voltage present at the feed point. This ensures emission-free lifting and electrical travel of the crane along the quayside.