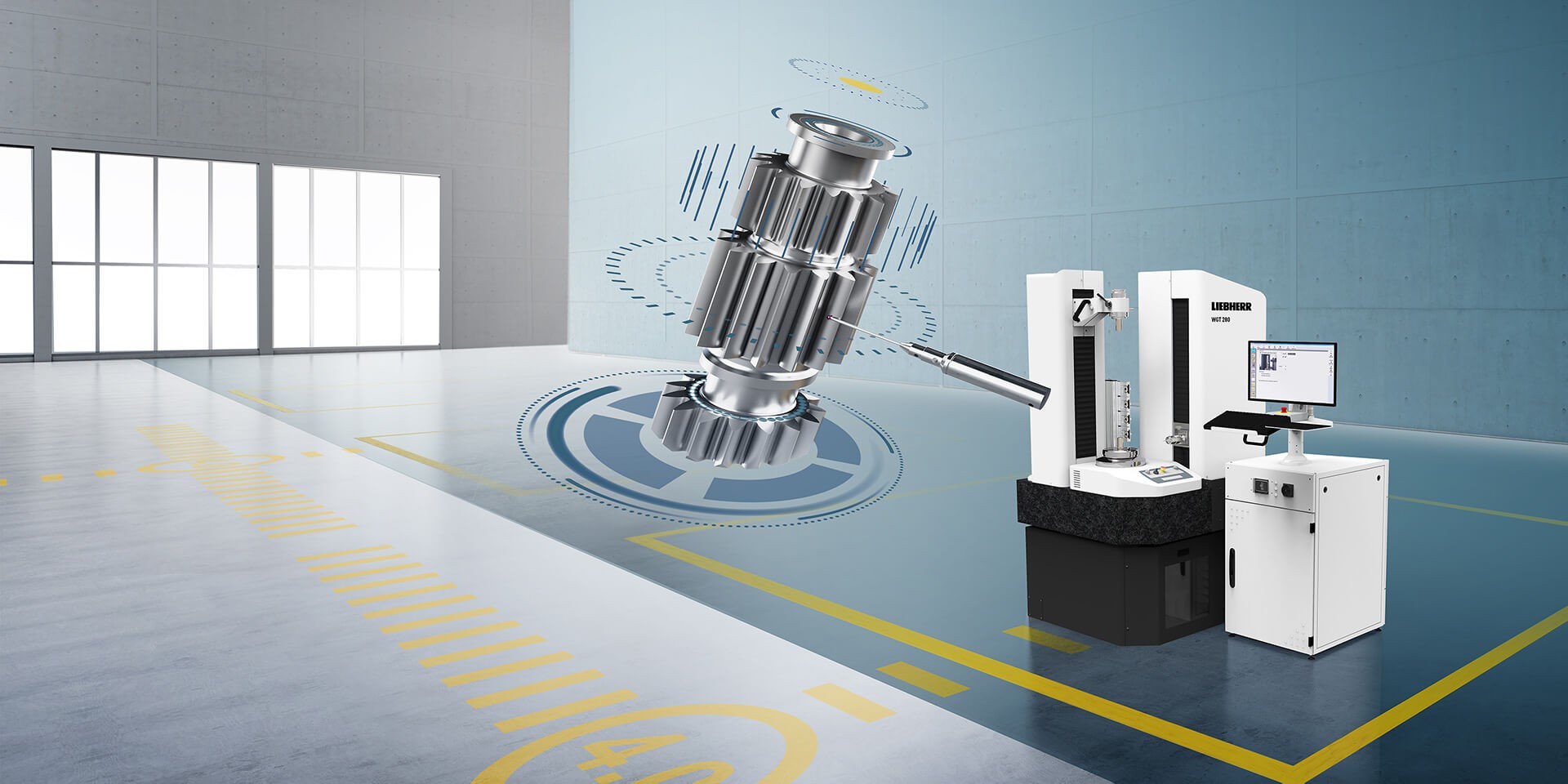

The Liebherr range of gear measuring machines

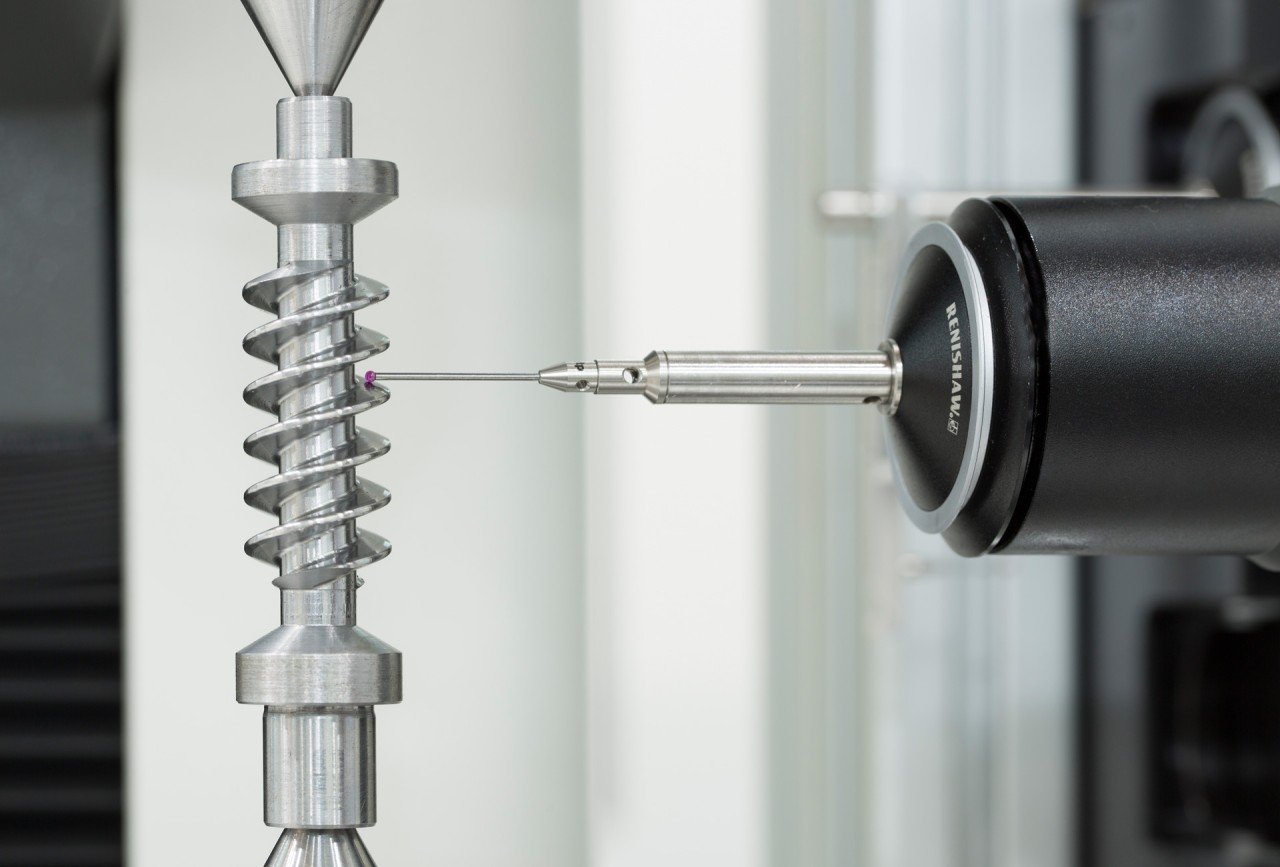

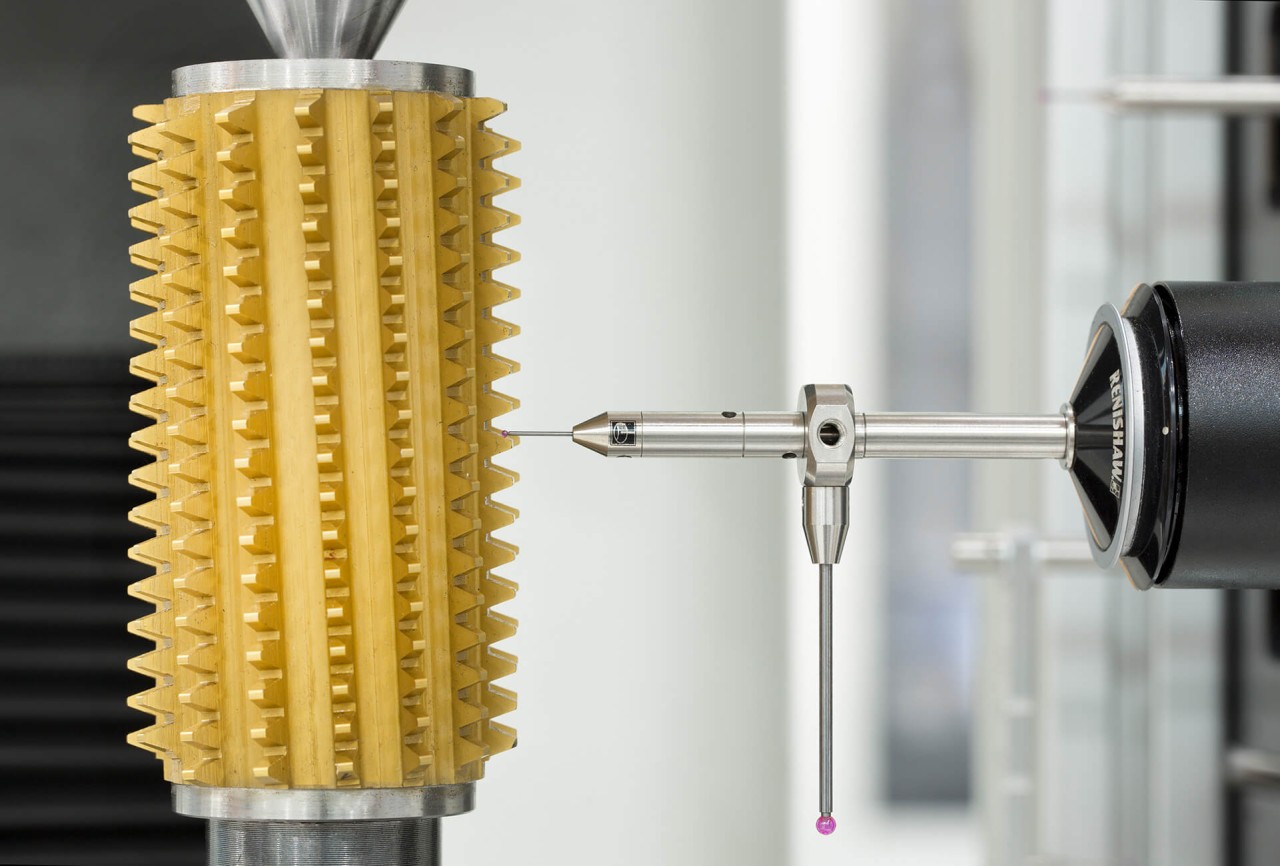

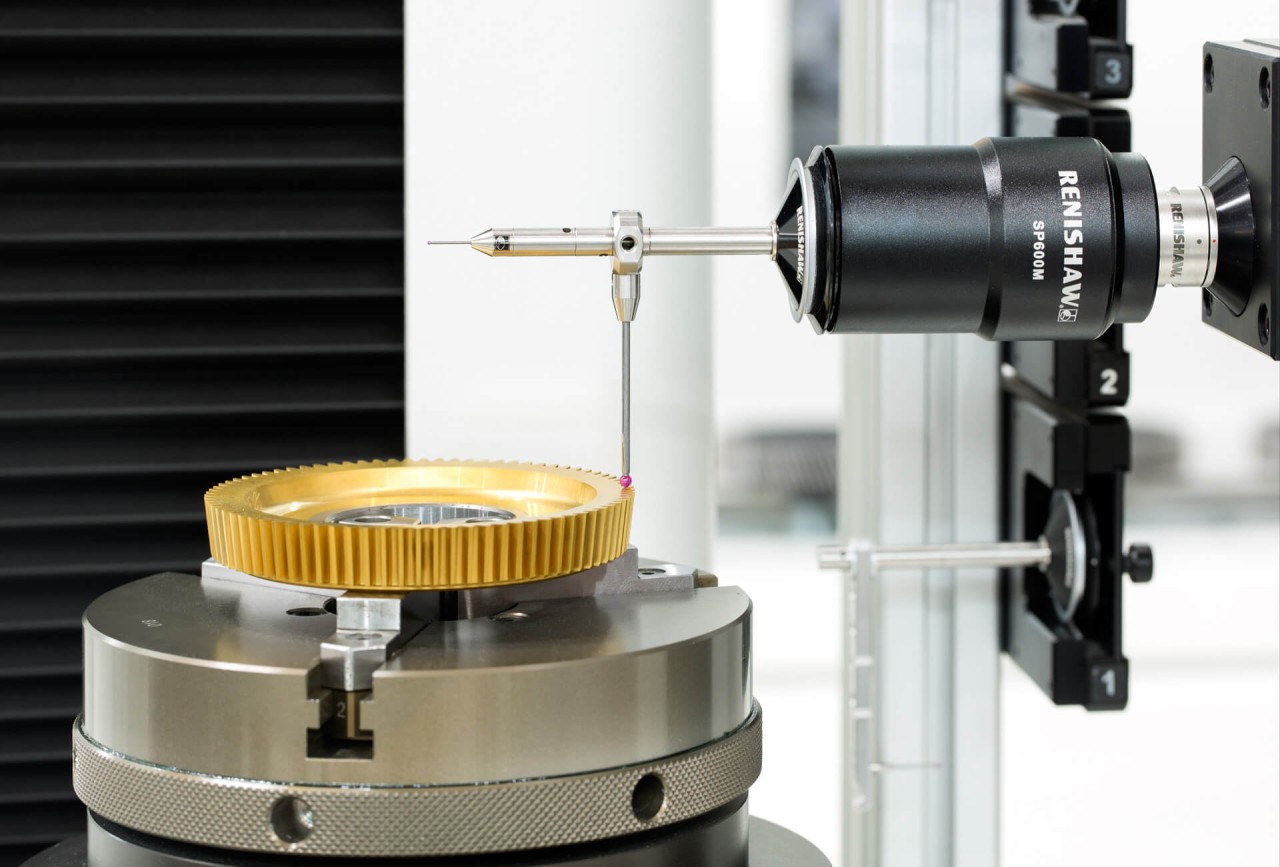

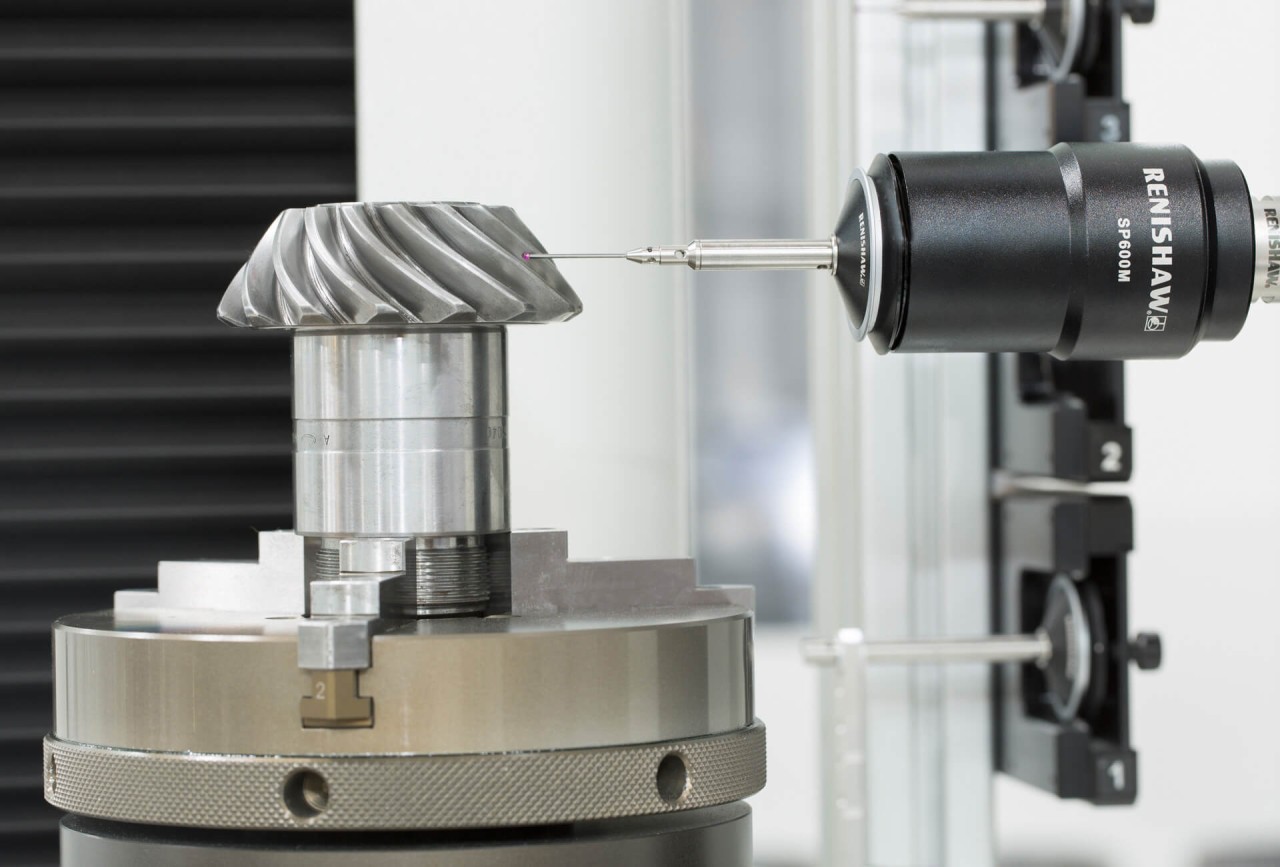

Liebherr offers a wide range of gear measuring machines. The combination of high-precision measuring mechanics and the specially developed gear measuring software guarantees precise measuring results.

Metrology

The Liebherr gear measuring machines are focused on ergonomics and usability, precision, robustness, durability and serviceability. The measuring machines and the corresponding software are used in various sectors, such as automotive, aerospace, and general mechanical engineering.

01/04

Portfolio

Other variants on request

| Max. Ø [mm] | Max. width [mm] | Max. table load [kg] | |

| LMC 280 G | 280 | 530 | 80 |

| LMC 400 G | 400 | 530 / 650 | 180 |

| LMC 600 G | 600 | 650 / 800 | 400 |

| LMC 850 G | 850 with tailstock 1000 without talstock | 1000 / 1500 | 3000 |

| LMC 1200G | 1200 with tailstock 1400 without tailstock | 1000 / 1500 | 3000 / 5000 |

01/02

01/02

More information on metrology

Read interesting articles from our customer magazines and press releases