Precise – reliable – cost-effective

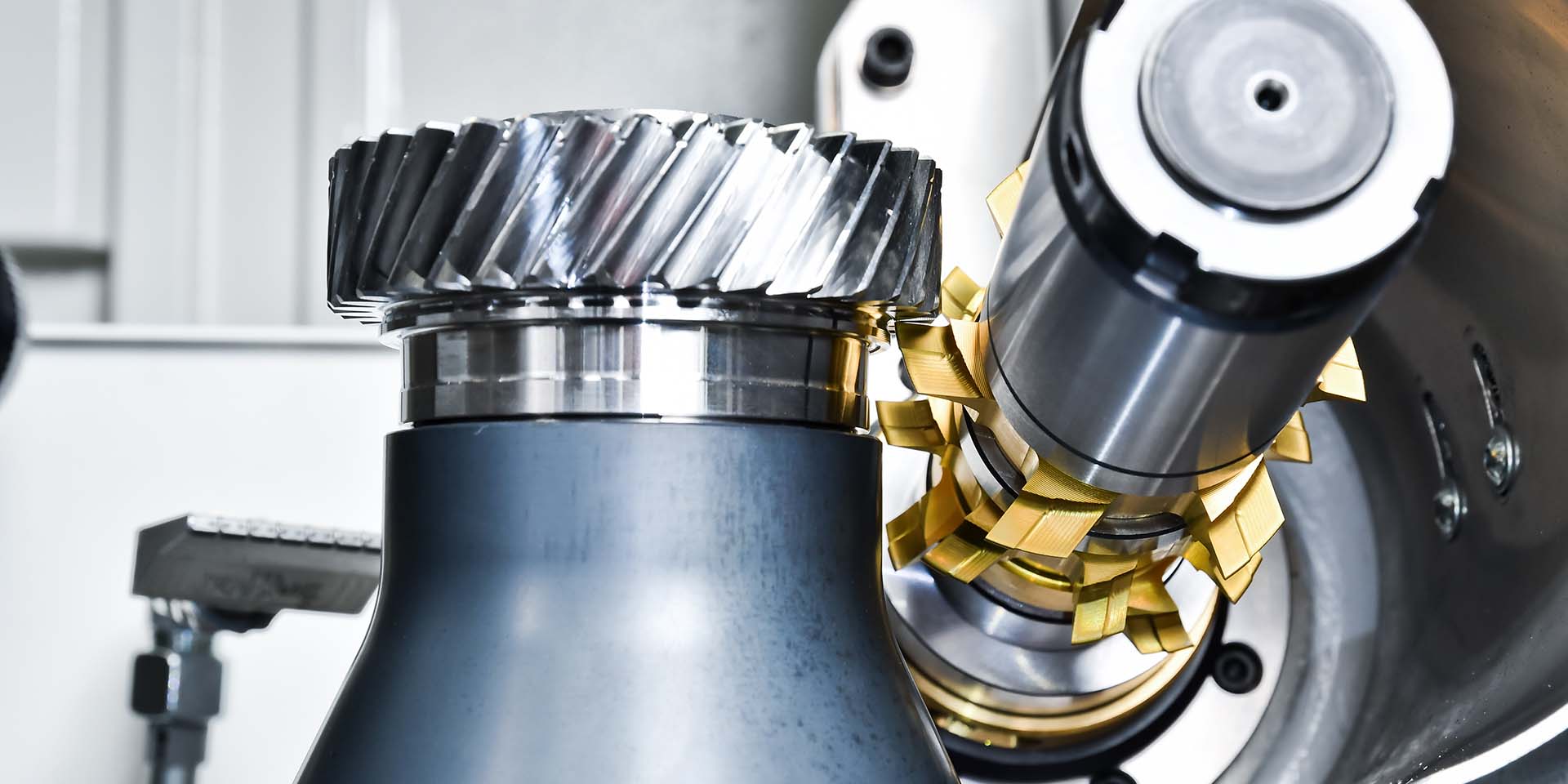

This is the chamfering process.

After chamfering with the patented ChamferCut technology, no additional machining is necessary. There is no need for a second cut, which is often required during the deformation-based deburring process for the removal of build-up material. With the chamfering process, the exact chamfer form is produced. In contrast to deformation-based processes, the material structure is not affected. An optimal starting point is created for the subsequent finishing of hardened gears, particularly gear honing. The quality of such chamfers defines a new standard – with maximum repetitive accuracy.

Advantages

The ChamferCut process

- Very precise chamfer geometry

- Premium chamfer quality and reproducibility

- No bulging or material deformation

- Standard tooth-root chamfering

- Established process in gear production

- Very long tool life

- ChamferCut tools can be re-sharpened approx. 20 times easily and cost-effectively

- Lower tool costs compared to alternative processes

- Short amortization period due to low tool costs

- Applications for gears with module 0.8-42 mm

- 2nd cut not needed for gear hobbing - longer tool life for the hobbing tool

- Short setup time

Liebherr solution

Videos

- ChamferCut

- LC 180 DC

- LC 300 DC

- LD 300 C

ChamferCut

ChamferCut

Economic efficiency

| Workpiece (chamfering) | |||

| Workpiece | speed gear | ||

| Module | 2.7 mm | ||

| Number of teeth | 41 | ||

| Helix angle | 24.5° | ||

| Press chamfering (with burnishing) | ChamferCut | ||

| Press chamfering tool | 4,700 Euro | Chamfer cutter (set) | 3,600 Euro |

| Number of re-sharpenings | 1 | 23 | |

| Total workpieces | 95,445 | 468,293 | |

| Tool costs/workpiece | 6.7 cents | 1.5 cents | |