Magazine 2019

Magazine 2019

When Peter Pruschek, Head of Electronic and Control System Development at Liebherr-Verzahntechnik GmbH, presents the new LHGearTec control system, he first highlights the striking new features: “We are entering the market with a 24 inch touchscreen monitor – an above-average size for machine tools.

Most read

01

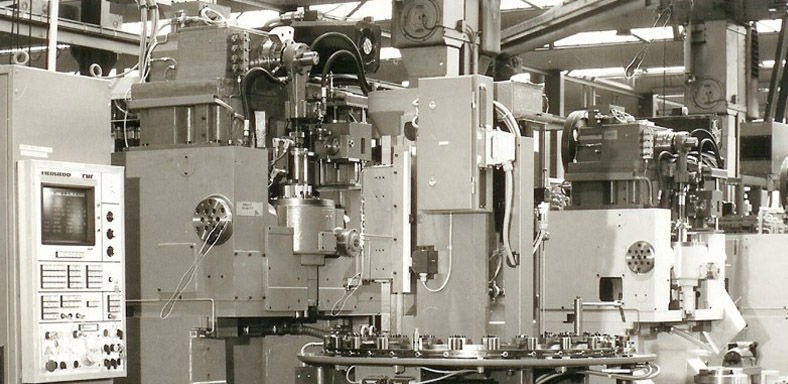

Half a century of Liebherr-Verzahntechnik GmbH means 50 years of commitment to the machinery and plant engineering industry. Gear technology originated in the technology of the revolving tower crane. Hans Liebherr wanted to buy a gear hobbing machine for gear manufacturing, but could not find what he wanted – so he simply built it himself. It’s a typical Liebherr story, since many sectors in the company group have emerged in this or in a similar way. Taking things into one’s own hands: an attitude that can still be found at Liebherr today.

02

Bauer Gear Motor operates two new LC 180 gear hobbing machines at its facility in Slovakia, producing gearing for all facilities. These machines are characterised by their operational versatility, given that they are used to produce around 180 different components in a very wide range of different sizes.

03

“The fire pump is the heart of every fire truck”, explains Michael Schöftner, Head of Mechanical Production at Rosenbauer International AG, the global leader for fire service equipment. The equipment has to withstand enormous loads in cases of operation. Rosenbauer relies on an automation solution for pump manufacturing from Liebherr. The rotary loading system RLS 800 from the Kempten-based automation experts has been deployed in Leonding near Linz for around two years now.

“The fire pump is the heart of every fire truck”, explains Michael Schöftner, Head of Mechanical Production at Rosenbauer International AG, the global leader for fire service equipment. The equipment has to withstand enormous loads in cases of operation. Rosenbauer relies on an automation solution for pump manufacturing from Liebherr. The rotary loading system RLS 800 from the Kempten-based automation experts has been deployed in Leonding near Linz for around two years now.

Lisa Bozzi has been with Liebherr in Saline, Michigan, since 2017. She is an office manager and event coordinator for the Liebherr Gear Technology and Automation Systems division, but also supports the HR team in acquiring new talent for Gear Technology and Automation Systems and Aerospace.

How do you get closer to the customer? For Liebherr the answer is simple: by increasing presence locally.

As before, ChamferCut is a technology with a great deal of development potential. A new upgrade is now pushing the limits of the impossible.

Due to the high demand, the automation division of Liebherr-Verzahntechnik GmbH has restructured the area of robotics and made it a separate department. The editors of Liebherr Magazine went to visit and had a look around.

While we still have some way to go to achieve autonomous driving on the road, factories are miles ahead: AGVs (automatic guided vehicles) are already being used in the area of production.

The aircraft propulsion systems of today are wonders of technology. Since air travel is rapidly growing in demand around the world, the production technology employed until now needs to be modernised.

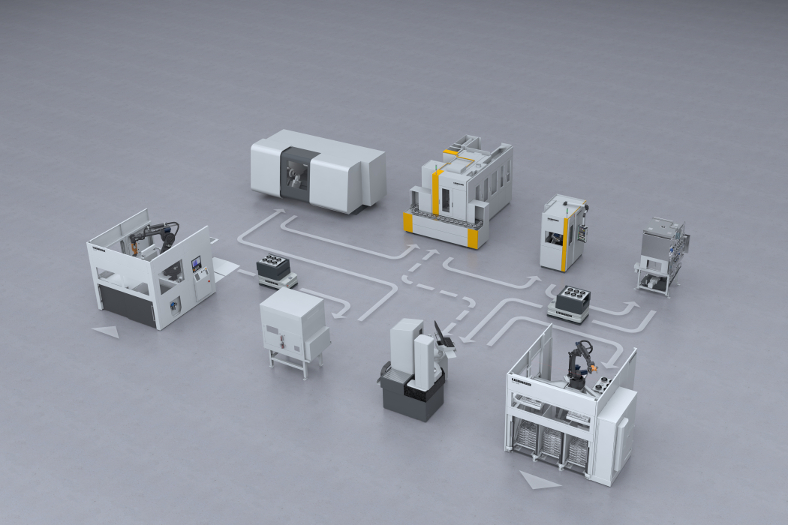

The constantly rising demands from the markets, such as higher accuracy, more effective processes and increased flexibility, require sophisticated machine concepts. For this reason, the new gear skiving machine generation has been equipped among other things with a tool changing system integrated in the machine, multi-machining functions, an integrated measurement device for tools and the option of chamfering during the machining process.