Automation solutions for aviation

Aviation

Highest demands on material, quality and efficiency

From small to large, top performance is achieved every day in aerospace manufacturing. From high-precision components for landing gear or flight controls to large valve blocks or structural components, high-quality, reliable and on-time manufacturing processes are crucial but so too are costs.

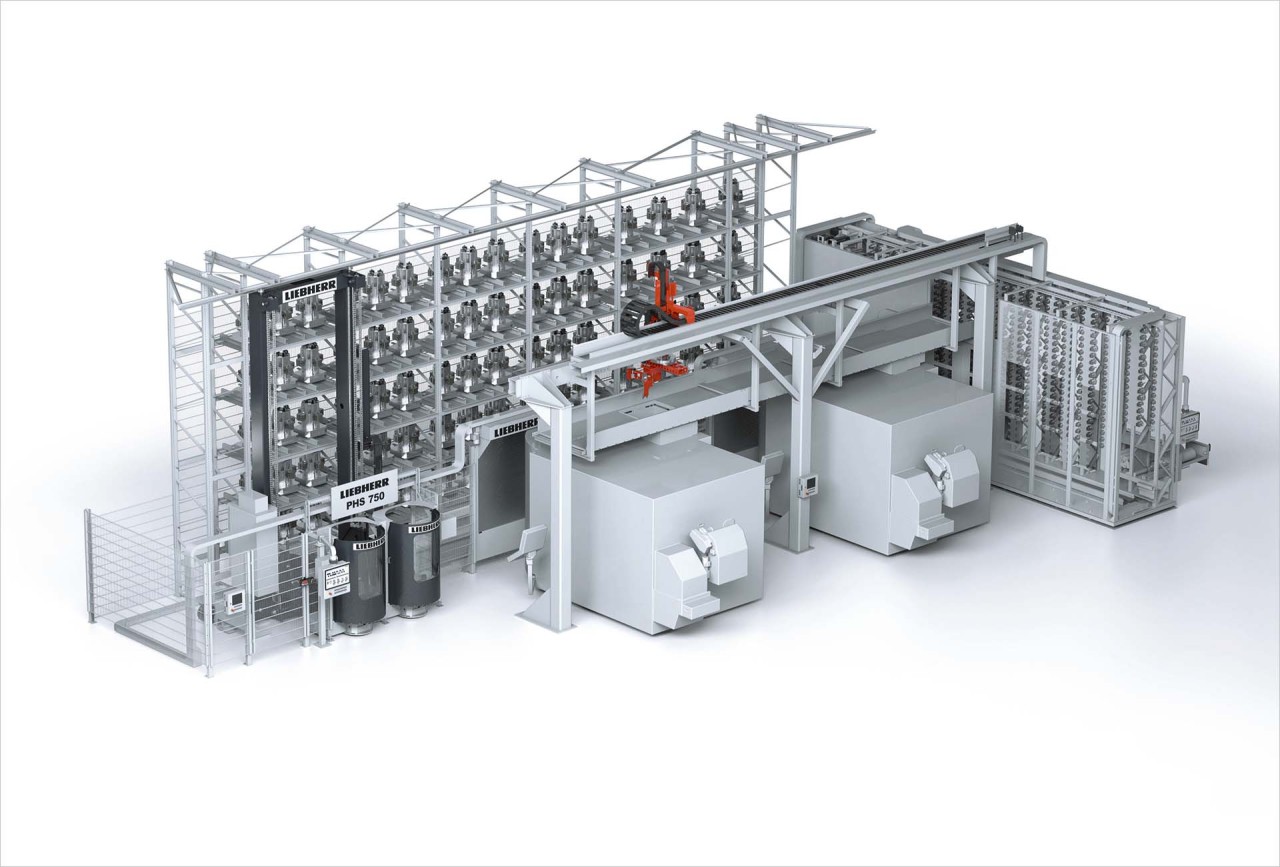

The increased volume of air traffic is leading to rising demand and manufacturing capacities have to be expanded. At the same time, more competitors are entering the market and price pressure is increasing. We want to help meet these challenges and ensure the ideal utilization and therefore cost-effectiveness of your high-tech machines with intelligent automation concepts. Low-manpower manufacturing can reduce costs and alleviate the shortage of skilled workers. Automated processes improve planning reliability and adherence to schedules and enable just-in-time component manufacturing.

Aerospace: How to automate your manufacturing

Flexible manufacturing system at MTU: blade production with autopilot

The system we have created together is very complex and far ahead of the previous state of the art.

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).From the development phase to commissioning, mutual trust and close communication were crucial to our success. With Liebherr-Verzahntechnik as our industrial partner, we can continuously improve the reliability of our production equipment and guarantee optimum performance.

Contact your sales partner:

By clicking on “ACCEPT”, you consent to the data transmission to Google for this map pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each Google map individually in the future and want to be able to load them without this blocker, you can also select “Always accept Google Maps” and thus also consent to the respectively associated data transmissions to Google for all other Google maps that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and thr Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).