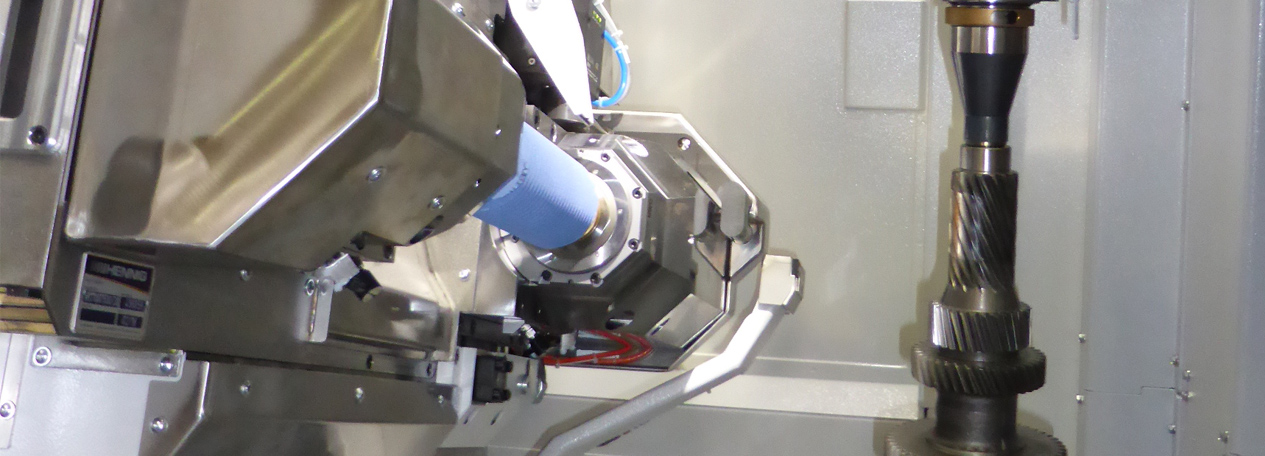

The LGG 400 M has been developed with an eye towards aerospace and job shop customers. It fits into the same footprint as its little sister, the LGG 280, but has grown in height. With a different housing and a column extension, it is perfect for machining long shafts because the travel of the main and counter column has been extended.

"Our users can utilize a variety of grinding heads for internal and external gears," says Oliver Kraft, Manager Development and Design of Gear Cutting Machines. "They can perform generating grinding with high productivity on workpieces up to 280 millimeter in diameter or profile grinding on even larger components up to 400 millimeters. This means even greater flexibility then its sister machine."