Liebherr on the Rolls-Royce UltraFan®

Liebherr-Aerospace and Rolls-Royce have established a 50:50 joint venture called Aerospace Transmission Technologies GmbH to develop manufacturing capability and capacity for the power gearbox for Rolls-Royce’s new UltraFan® engine.

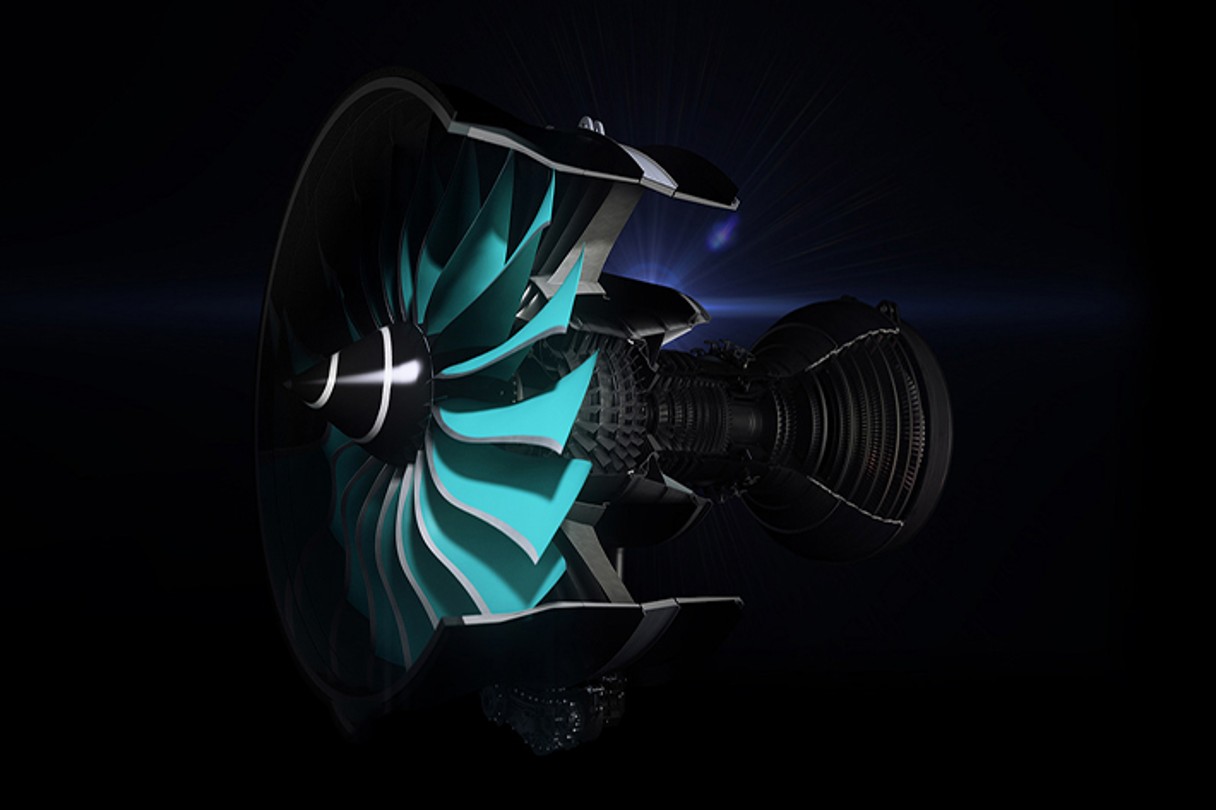

UltraFan ® - Photo : Rolls-Royce plc

The power gearbox

The power gearbox will enable the UltraFan®, a geared design, to deliver efficient power over a range of take-off thrusts for high-bypass ratio engines of the future. For the highest thrust engines, each single gearbox will be capable of handling the equivalent horsepower produced by more than 500 family cars. UltraFan® is based on technology that could be ready for service from 2025. It will offer at least 25 per cent improvement in fuel burn compared with the first generation of Rolls-Royce Trent engines.

First run

In October 2016, Rolls-Royce has run the gearbox for the first time at its new test center in Dahlewitz south of Berlin, marking a significant step in the development of the UltraFan® engine design.

The first run took place on Rolls-Royce’s altitude rig, which allows engineers to simulate the effects of the gearbox being on the wing of an aircraft that is climbing after take-off, coming in to land or banking while in flight. The initial run confirmed rig dynamics and oil system functionality at low pressures and speeds.

Aerospace Transmission Technologies - The joint venture

Located in Friedrichshafen (Germany), the joint venture Aerospace Transmission Technologies GmbH (ATT) provides production engineering for the power gear drive train components. The manufacturing of the components is initially being done in existing Liebherr facilities, more precisely in its Friedrichshafen plant, which is Liebherr-Aerospace’s center of excellence for helicopter and aircraft gears and gearboxes, and in its plant in Biberach an der Riss (Germany), which specializes in the manufacture of planetary gears and other components. These are used in a wide range of products such as Liebherr cranes, mining trucks, earth moving applications and port equipment as well as in wind power plants. As production volumes increase, the joint venture will look at options for creating a standalone manufacturing infrastructure.

Apart from Liebherr’s know-how in the production of gears, ATT also benefits from the Group’s expertise in machining centers for gears, which it has been developing and manufacturing in its plant in Kempten (Germany) for decades.

Rolls-Royce leads the design definition and design integration of the power gearbox, as well as the testing activities.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Video: Rolls-Royce Power Gearbox New Test Centre

Contacts

Adelheidstrasse 40

88046 Friedrichshafen

+49 7541 40280-0

[email protected]